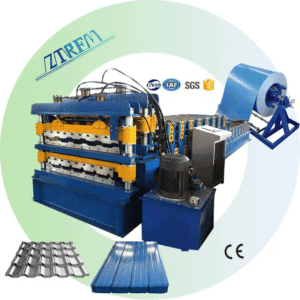

Zhongtuo Roll Forming Machinery (machines de formage de rouleaux)

fabricants de machines à fabriquer des tôles de couverture

One-Stop Supplier Of roof sheet making machine

Global Trust : Trusted by customers in over 156+ countries and regions, our roofing sheet making machines are recognized for their outstanding performance and reliability worldwide.

Excellence certifiée : Avec plus de 25 certifications ISO9001 et CE, nos machines répondent aux normes internationales les plus strictes, ce qui vous garantit une qualité et une sécurité optimales.

Fournisseur unique : From essential parts to complete roof sheet forming machines, we offer a one-stop solution that simplifies the procurement process, saving you time and reducing complexity.

Gamme complète de produits : As a leading roofing sheet making machine manufacturer, we provide a full spectrum of products tailored to meet your specific production needs, including versatile roofing sheet manufacturing machines and precision-engineered roof sheet forming machines.

Expert Support: Our dedicated team is here to assist you at every stage, ensuring that you select the right equipment and receive ongoing technical support to maximize your operational efficiency.

Machine à former les tôles de toiture

Pourquoi zhongtuo est-il votre premier choix pour

roof sheet making machine?

Technologie des services de renseignement de pointe

OEM/ODM et service de personnalisation à guichet unique

Zhongtuo Cold Rolling Forming Machine Factory Has The Rolling Machine Deign Experience Of More Than 10 Years. For The Metal Roofing Sheet Sheets Machine, We Have The Following Popular Designs Like, Roof Sheet Forming Machine, Corrugated Board Rolling Forming Machines, Step Tile Rolling Machines, Glazed Tiles Rolling Machines, Sandwich Panel Panel Rolling Machines And Others.

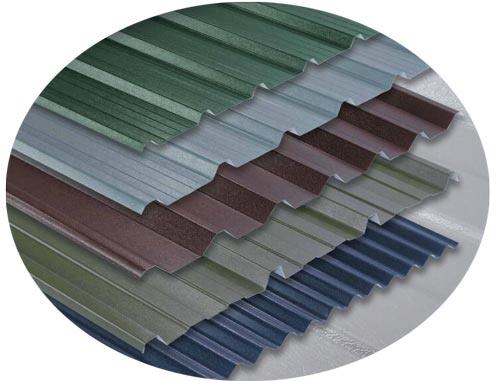

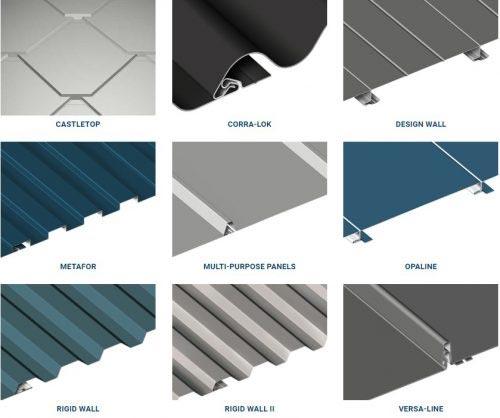

Nous disposons d'une large sélection de machines de fabrication de tôles de toiture. Les tôles de toiture métalliques sont une option abordable et durable, capable de résister à des températures élevées. A cette fin, ZTRFM Roofing Former vous propose des machines de fabrication de plaques de toiture et des machines de formage de panneaux de toiture de haute qualité. En tant que l'un des principaux fabricants de machines de fabrication de plaques de toiture, nous fournissons les systèmes de toiture les plus fiables et les plus abordables disponibles sur le marché, avec une gamme de conceptions et de styles parmi lesquels choisir. Le groupe ZTRFM personnalise également divers types de plaques de toiture et de panneaux muraux pour répondre à vos besoins spécifiques, y compris :

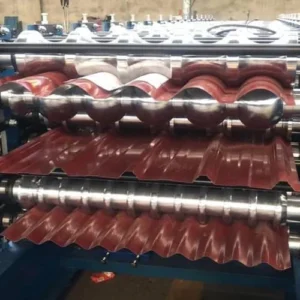

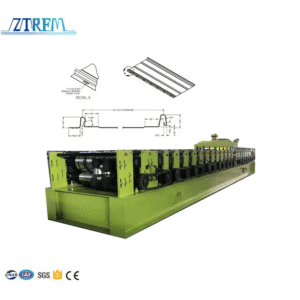

Éléments de la machine et détails de chaque pièce Introduction :

En fait, la plupart des machines de formage par laminage des tuiles sont composées des éléments suivants :

Dévidoir : Nous disposons de modèles manuels ou hydrauliques de 5 tonnes, 7 tonnes, 10 tonnes ou autres.

Principale machine de formage par laminage : La station de laminage et les éléments de détail seront conçus en fonction des exigences du client et des profils de dessin ;

Table de réception, nous disposons d'un manuel et d'un empileur entièrement aromatique.

Comment concevoir les bonnes machines à fabriquer les tôles de couverture ?

Pour toutes les machines de couverture métallique, nous les personnalisons en fonction des exigences du client. Nous avons d'abord besoin du profil du dessin du client, puis nous pouvons fournir le plan de conception approprié.

Étape 1 : Établir le profil :

Obtenez le profil du dessin et donnez ensuite au client un retour d'information approprié. Prenons l'exemple du profil de dessin suivant :

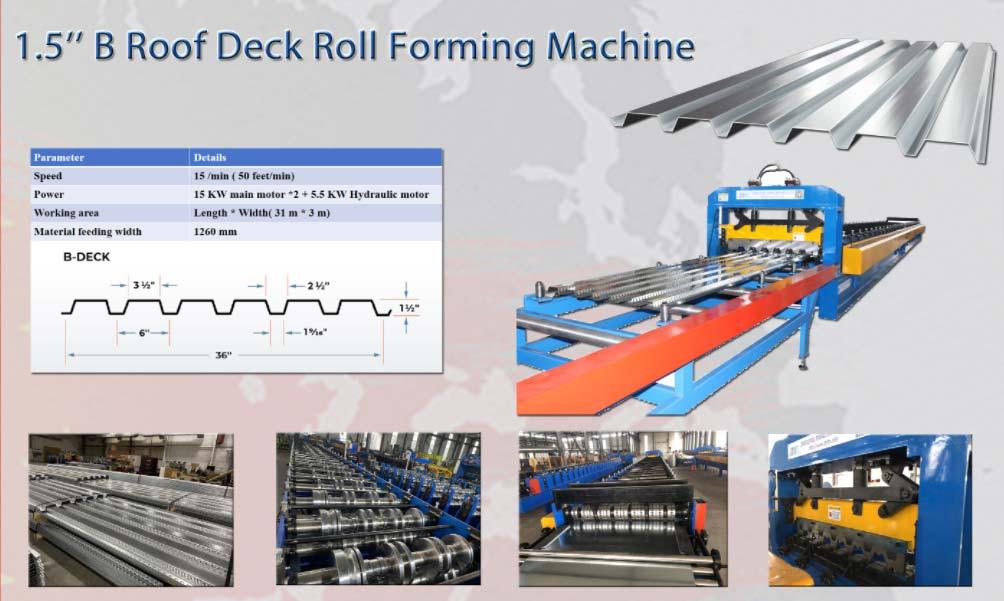

En fonction du profil du dessin, nous pouvons simplement dire que ce profil de dessin provient d'Amérique du Nord. Nous devons ensuite confirmer avec le client la largeur de la bobine et la dureté du matériau. Si le matériau est différent, la conception de la machine sera différente. Nous fournirons alors un profil de dessin précis en entrant la largeur de la bobine et nous confirmerons ensuite avec les clients. Entre-temps, nous recommandons d'autres modèles populaires aux États-Unis que les clients peuvent choisir.

Étape 2 : Conception de la machine en fonction des exigences du client :

Par exemple, si le client a des exigences en matière de vitesse, nous avons des options de machine à plaques de couverture métalliques à boîte de vitesses rapide. Si le client a des exigences en matière de durabilité, nous pouvons lui recommander une machine à plaques d'étanchéité métalliques à cadre de moulage robuste.

Étape 3 : Confirmation de la commande et organisation de la production :

Lorsque la commande est finalisée, nous tamponnons et signons le contrat et le devis, puis nous les envoyons au client. Une fois que nous avons reçu l'acompte du client, nous organisons la production. Mais avant d'organiser la production, nous fournissons le fichier 3D ou CAO de l'agencement et de la conception de la machine, puis nous confirmons avec le client la couleur de la machine, l'électricité et d'autres éléments.

Étape 4 Essai et organisation de la livraison de la machine à fabriquer des plaques de couverture métalliques.

Contrairement à d'autres usines, la machine de test de tôles de couverture métallique ZTRFM utilise la bobine et non la tôle unique. Normalement, le test d'une seule feuille ne permet pas de détecter les problèmes majeurs lors du laminage, comme la mesure de la longueur qui n'est pas exacte, le balancement de la feuille ou d'autres problèmes. En un mot, nous testons les machines sérieusement, comme si le client était là. Entre-temps, nous disposons de 12 caméras Web dans notre usine, ce qui vous permet de vérifier les essais de la machine à l'aide de la caméra Web à tout moment.

Pour d'autres conceptions de tôles de couverture, ZTRFM dispose de plus d'options pour votre référence :

Machine pour toitures métalliques

Améliorez votre jeu de construction avec la précision et la fiabilité de Machine pour toitures métalliques, Notre machine à recouvrir les toits métalliques, votre solution pour une couverture métallique impeccable. Conçue pour répondre aux exigences des projets de construction modernes, notre machine à recouvrir les toits métalliques garantit la durabilité et l'esthétique. Parfaite pour les applications commerciales ou résidentielles, elle rationalise le processus d'installation, ce qui vous permet d'économiser du temps et des ressources. Faites confiance à In Machine pour toitures métalliques La technologie de la toiture métallique permet d'obtenir des résultats professionnels qui résistent à l'épreuve du temps. Mettez-vous à niveau dès aujourd'hui et assurez-vous que chaque projet est couronné de qualité et d'efficacité, grâce à l'expertise des machines de couverture métallique.

Machine de fabrication de tôles de toiture

Transformez vos projets de toiture avec une efficacité inégalée grâce à la technologie Machine de fabrication de tôles de toiture, Notre machine à fabriquer des plaques de toiture est la meilleure solution de l'industrie pour la production de plaques de toiture de haute qualité. Notre machine à fabriquer des plaques de toiture est conçue à la perfection, garantissant des plaques à la fois durables et résistantes aux intempéries. Idéale pour les entrepreneurs et les fabricants à la recherche d'un rendement supérieur, cette machine garantit des performances constantes et une grande facilité d'utilisation. Découvrez la différence en termes de productivité et de qualité d'exécution grâce à l'intégration d'une machine de fabrication de tôles de toiture. Machine de fabrication de tôles de toiture dans vos opérations. Avec notre machine à fabriquer des plaques de toiture, vous ne vous contentez pas de construire des toits, vous créez des impressions durables qui définissent l'excellence dans le secteur de la construction.

Machine à sertir les tôles de couverture

La technologie avancée de notre machine à sertir les tôles de toiture permet à vos projets de toiture d'atteindre de nouveaux sommets. Conçue pour la précision et la durabilité, notre Machine à sertir les tôles de couverture Elle garantit des bords ondulés impeccables sur chaque feuille, améliorant à la fois la résistance et l'esthétique. Parfaite pour les professionnels exigeant des résultats de premier ordre, cette machine rationalise le processus de couverture et simplifie les installations complexes. Que vous vous attaquiez à des constructions résidentielles ou commerciales, faites confiance à notre système d'assemblage. Machine à sertir les tôles de couverture Pour un rendement constant et de haute qualité. Découvrez la différence d'efficacité et de fiabilité que notre machine à sertir les tôles de couverture apporte à chaque chantier.

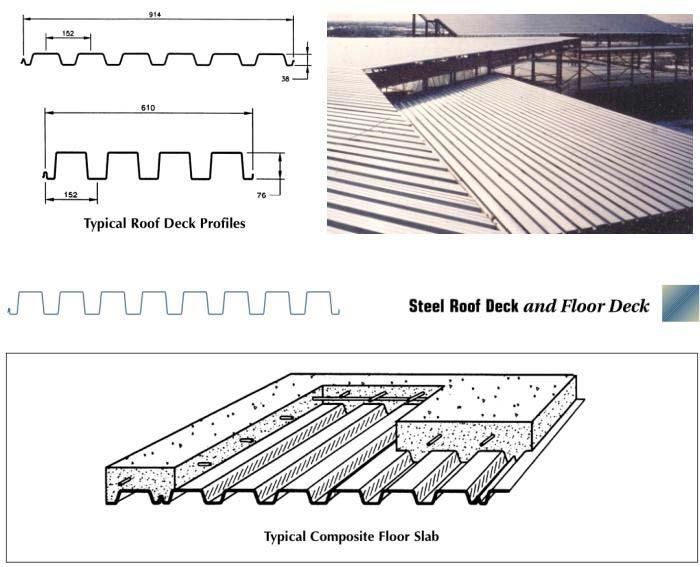

Machine à former des rouleaux de plancher

Libérez le potentiel de vos projets de construction grâce à l'application Machine à former des rouleaux de plancher, Cette machine est indispensable dans le secteur du bâtiment, en particulier dans les constructions à plusieurs étages, les ponts et les installations industrielles, où sa capacité à produire des planchers solides, légers et résistants au feu est essentielle. Cette machine est indispensable dans l'industrie du bâtiment, en particulier dans les constructions à plusieurs étages, les ponts et les installations industrielles, où sa capacité à produire des planchers solides, légers et résistants au feu est cruciale. La profileuse pour planchers transforme les tôles plates en profilés ondulés, ce qui améliore l'intégrité structurelle tout en facilitant une installation rapide. En intégrant une Machine à former des rouleaux de plancher En l'intégrant à vos activités, vous pouvez réduire considérablement les délais de construction et les coûts des matériaux. Son application dans divers secteurs, des complexes commerciaux aux ensembles résidentiels, démontre son adaptabilité et son efficacité à répondre à diverses exigences architecturales. Avec la profileuse de planchers, l'avenir de la construction s'ouvre à vous : l'innovation rencontre la praticité.

Voici quelques dessins de profils populaires pour votre référence, veuillez consulter le Flipbook pour choisir le dessin approprié et ensuite nous pourrons faire un devis précis.Feuille de toiture avec feutre de forme PE ou matériau anti-condensation.

Envoyez votre demande dès aujourd'hui

Plus de 250 entreprises lui font confiance

des entreprises de haute qualité. En coopérant avec nous, elles ont reçu

Le groupe a bénéficié d'un soutien solide et a réalisé des percées et des développements commerciaux.