Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

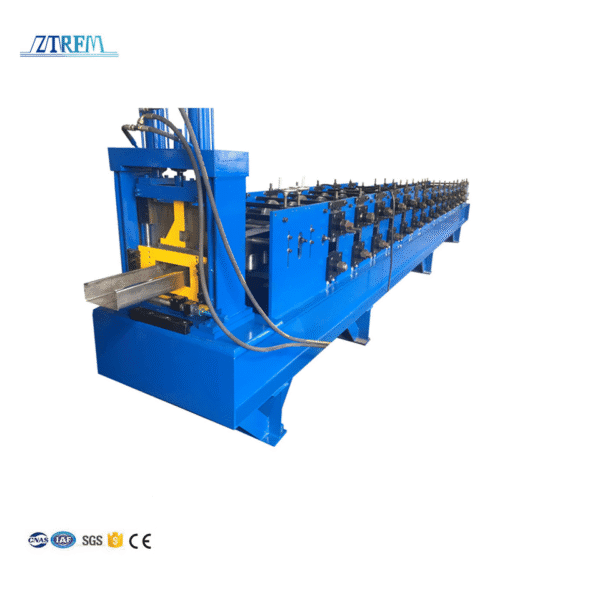

High Speed and High Precision C purlin Steel Forming Machine

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

Amid the global trend toward lightweight and standardized steel structures, C-shaped purlins have emerged as the go-to choice for roof and wall support, thanks to their optimized cross-sectional design, easy installation, and cost-effectiveness. From roof supports in small-to-medium industrial plants to wall studs in warehouses, from secondary beam systems in steel residential buildings to structural frameworks in agricultural greenhouses, C-shaped purlins now serve as versatile components across the construction industry. Their manufacturing quality directly determines a building’s stability and longevity.

Core working principle: one-click molding automation logic

The C Purlin Roll Forming Machine features end-to-end automation covering ‘sheet material feeding, continuous rolling, precision cutting, and finished product output’, seamlessly transforming metal coils into C-shaped purlins with zero manual intervention. This innovation dramatically boosts production efficiency and ensures product consistency.

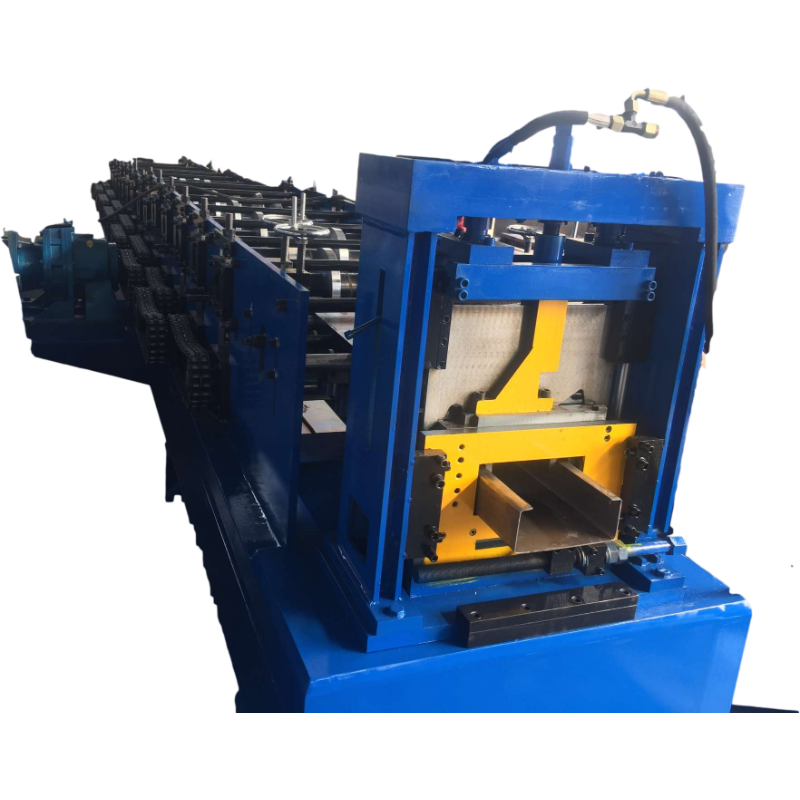

The production process begins with an intelligent feeding system. Metal coils—such as galvanized steel, color-coated steel, and aluminum-magnesium-manganese alloy—are smoothly unwound by a hydraulic uncoiler. Simultaneously, a feeding and leveling device ensures the coils are perfectly flat and properly guided, guaranteeing a flatness error of less than 0.3mm when entering the forming unit. The coils then proceed to a forming system comprising 12-16 precision rolls arranged in a C-shaped purlin cross-section curve. Through controlled pressure, the flat sheets are progressively rolled into standard C-section profiles with flanges and webs. A real-time pressure monitoring system automatically adjusts the rolling force during the process, preventing wrinkles or cracks in the sheets.

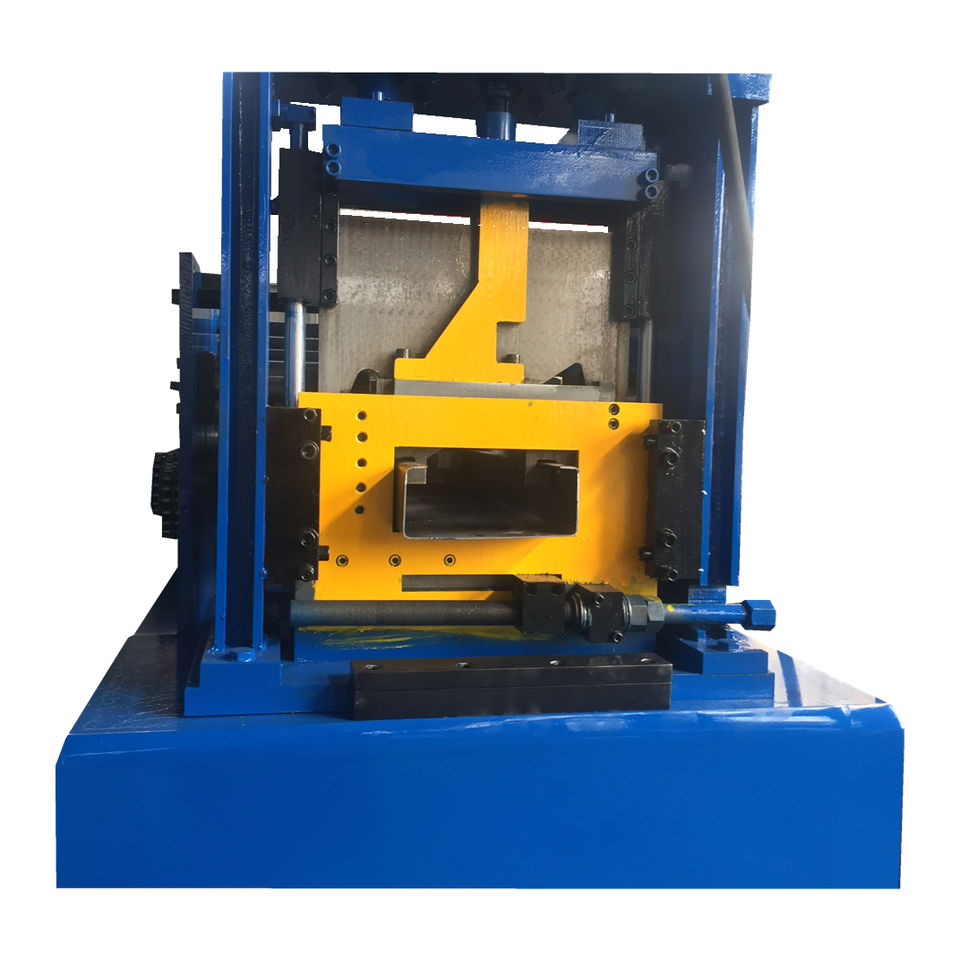

The formed continuous C-shaped purlins proceed to the CNC-controlled fixed-length cutting stage. A high-speed cutting system powered by an imported servo motor ensures precise cutting according to preset dimensions (with 0.1mm-level parameter adjustment capability), maintaining length accuracy within ±1mm tolerance.

Key Construction Highlights: Quality Guarantee for Global Operating Conditions

As a core equipment for the global market, the C Purlin Roll Forming Machine is designed with regional operational requirements in mind. From its core components to the structural framework, it features high-standard configurations to ensure stable performance across diverse environments.

The core roll system employs imported alloy steel (42CrMo) with quenched and tempered treatment, achieving a surface hardness of HRC58-60 and nitriding treatment. This process quadruples wear resistance compared to conventional steel, enabling continuous processing of 500 tons of coils without significant wear. The rolling process utilizes a five-axis CNC machine tool, ensuring each roll set maintains a roundness error below 0.01mm and a gap uniformity within 0.02mm, providing fundamental assurance for the cross-sectional precision of C-shaped purlins.

The equipment features a high-strength welded rectangular tube structure, with vibration aging treatment to eliminate internal stresses. This ensures a vibration amplitude of less than 0.1mm during high-speed operation (up to 25m/min) in environments ranging from-10℃ to 45℃. Additionally, it is equipped with an IP54-rated electrical control system, designed to operate in complex overseas environments such as humid and dusty workshops. The multi-language interface (supporting English, Spanish, Arabic, and other languages) meets the operational needs of operators from various countries.

International Standard Accuracy: Adapt to Global Building Code

The international market imposes stringent precision requirements on C-shaped purlins. Our equipment employs a triple control system combining CNC technology, precision rolling, and servo cutting, ensuring all specifications of the formed purlins meet global standards: flange verticality error ≤0.5, web flatness ≤1mm/m, and cross-sectional dimensional tolerance ≤±0.3mm. These specifications fully comply with the CE certification (EU), UL certification (US), and TISI certification (Southeast Asia) requirements.

High precision ensures not only product compliance but also boosts construction efficiency. In an Australian steel structure factory project, C-shaped purlins manufactured by our company achieved a 99% bonding rate with the roof color steel sheets. The installation required no on-site adjustments, cutting the construction period by 20% and earning high praise from the general contractor.

Multi-material adaptation: Meeting the climate needs of different regions

According to the climate characteristics and material preferences of different regions around the world, the equipment has super material adaptability and can process a variety of metal sheets with a thickness of 0.6-3.0mm and a width of 100-500mm: in high corrosion coastal areas, it can process 316L stainless steel or aluminum-zinc coated steel plates; in low-temperature areas, it can adapt to weathering steel materials; in the Southeast Asian market, where lightweight demand is prominent, it can perfectly process aluminum magnesium manganese alloy sheets.

Furthermore, the equipment supports customized roll design to meet client-specific requirements, enabling production of specialized products such as perforated C-shaped purlins (for pipeline installation) and reinforced C-shaped purlins (for heavy-duty applications). This capability addresses the personalized needs of construction projects across different countries, helping foreign trade enterprises expand into niche markets.

Global Application: Success Stories Across Five Continents

With internationally certified quality and globally optimized performance, our C Purlin Roll Forming Machine has been exported to over 60 countries and regions worldwide. It consistently delivers reliable performance across diverse climates and operating conditions, making it the preferred choice for numerous overseas enterprises.

In the European market, a German steel structure company adopted two of our equipment units. The C-shaped purlins produced by the company met precision standards and were successfully used in the expansion project of BMW Group’s Munich plant. The equipment operated continuously for six months without any failures, earning the customer’s recognition as ‘European-standard-grade equipment’.

In Southeast Asia, a Vietnamese agricultural technology company utilized our equipment to manufacture galvanized C-shaped purlins for constructing large-scale smart greenhouses, with the machinery optimized for local high-temperature and high-humidity conditions.

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.