Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

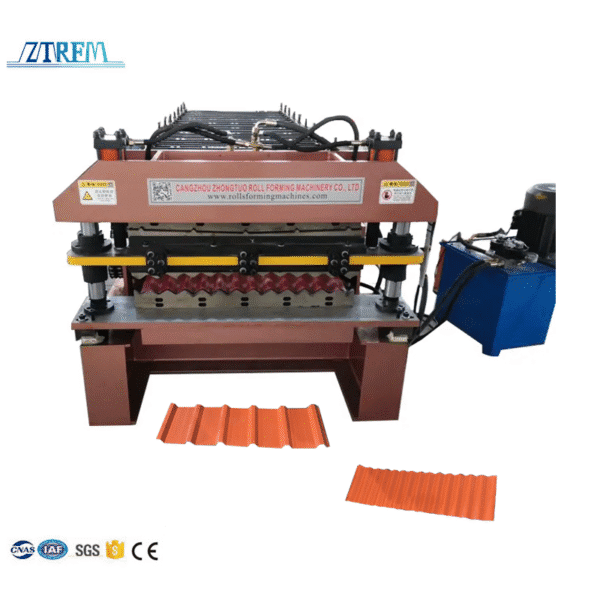

Double Layer Roof Sheet Rolling Machine:Driving the Energy-saving Revolution of Roof Building Materials Production

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

When “carbon neutrality” becomes a global consensus, the energy-saving transformation of the construction industry has shifted from optional to mandatory. As the primary carrier of energy loss in buildings, the energy-saving performance of roofs directly affects the green rating of buildings. Double-layer roof panels, with their composite advantages of “outer windproof and waterproof layer + inner thermal insulation layer,” have gained high recognition in both the LEED (Leadership in Energy and Environmental Design) certification and China’s green building evaluation standard (GB/T 50378), becoming the mainstream choice for industrial, commercial, and civil buildings. However, for manufacturing enterprises, how to achieve production goals of “low cost, fast delivery, and high customization” while meeting stringent standards has become a new industry challenge.

Regional customization design, compatible with global standards

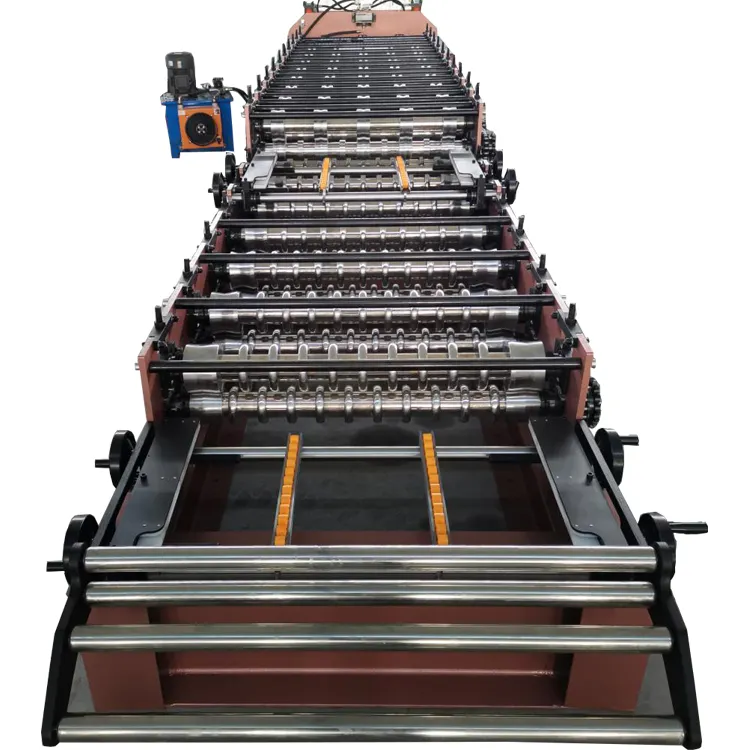

Through comprehensive research on building codes and climate characteristics across global regions, we have developed a flexible architecture combining “modular core + localized configuration” for the equipment. To address North American wind resistance requirements, the equipment features reinforced bite molding modules with “dual-roller synchronous engagement” technology, which increases roof panel edge-locking strength by 50%. Third-party testing confirms its ability to withstand winds up to 13 on the Beaufort scale, fully complying with U.S. FM Global certification standards. For Nordic insulation needs, the upgraded intelligent adhesive coating system incorporates a 3D visual inspection module to monitor core material coverage in real time, ensuring uniform composite density. The resulting roof panels maintain a stable thermal conductivity below 0.032 W/(m·K), meeting the energy efficiency requirements of EU CE certification.

To address corrosive environments in Southeast Asia, the equipment features scratch-resistant feeding channels integrated with a food-grade lubricant mist system, effectively preventing oil contamination and surface scratches on galvanized steel roof panels. These panels demonstrate over 1,000 hours of salt spray corrosion resistance in post-processing. The system also enables rapid parameter switching to meet regional standards—such as the EU’s 40mm wave height specification or the Middle East’s 60mm wave height standard—without replacing core components. This is achieved simply by selecting the corresponding regional template within the system.

Intelligent Interconnection System, Realizing Lean Production

The equipment is equipped with an Industry 4.0 smart control system, overcoming the limitations of traditional “single-machine operation” and achieving full-chain digitalization of “production-monitoring-management”. Through a 10-inch touchscreen, operators can monitor real-time operational parameters, production capacity statistics, and fault alerts. The system supports integration with corporate ERP systems to automatically generate production reports, enabling managers to accurately track production progress and cost consumption. For instance, when raw materials are nearing depletion, the system automatically sends alerts to the procurement department. When minor equipment malfunctions occur, it performs remote diagnostics and provides maintenance guidance, significantly reducing downtime.

For precision control, the equipment employs dual servo closed-loop control technology, achieving ±0.1mm feeding accuracy and a molding error of less than 0.3mm per meter, representing a 60% improvement over conventional systems.

High efficiency and energy-saving architecture, reducing the overall cost

The dual enhancement of efficiency and energy conservation delivers tangible cost savings for clients. Featuring a lightweight frame and energy-saving motor, the equipment reduces total power consumption to 22kW—70% less than conventional models. With a power usage of just 0.2 kWh per square meter of roof panel produced, it saves 1,200 yuan daily in electricity costs when operating at 8,000 square meters per day. The molding speed has been boosted to 25 meters per minute, enabling a single unit to produce 12,000 square meters daily—five times the output of traditional equipment. A South African client achieved 30% of local industrial roof panel demand with just two units.

In terms of labor cost, the equipment adopts a “one operator, multiple machines” management model, requiring only one operator per machine, which reduces labor input by 80% compared to traditional production. Additionally, the automatic lubrication and wear parts warning functions of the equipment keep the annual maintenance cost below 2,000 yuan, a reduction of 85% compared to conventional equipment.

Scenario-based solutions empower diverse needs

Industrial Plant: High Strength and Long Life

The equipment can produce heavy double-layer roof panels with a thickness of 1.5mm, which is designed with reinforced roller set to ensure the bending strength of the panels is more than 25MPa and the service life is more than 20 years.

Agricultural Greenhouse: High Light Transmission+Corrosion Resistance

Agricultural greenhouses require specialized light transmittance and corrosion resistance for their roof panels. Our equipment enables seamless processing of both PC boards and galvanized steel sheets. By precisely controlling roller pressure, we ensure less than 5% light transmittance loss in PC boards while preventing cracking. The double-layered greenhouse roof panels we produce not only deliver excellent thermal insulation but also resist corrosion from pesticides and fertilizers.

Commercial Building: Aesthetics+Customization

Commercial buildings like shopping malls and office towers have high demands for customized roof panel designs. The equipment supports the production of color-coated double-layer roof panels, and with customized molds, it can achieve various shapes such as corrugated and trapezoidal.

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.