Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

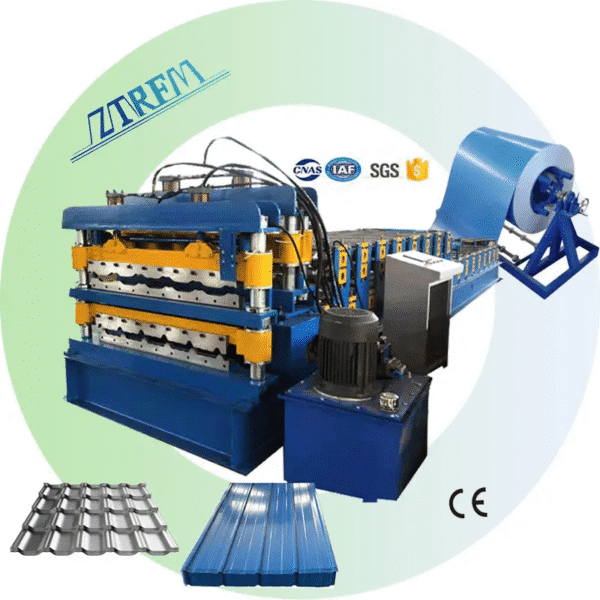

Double Layer Roof Sheet Roll Forming Machine:Build Efficient and Durable Building Protection Barrier

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

As the global construction industry shifts toward higher efficiency, energy conservation, and durability, roofs—functioning as the building’s’ first line of defense’—face increasingly stringent performance requirements. Double-layer roof panels, with their superior thermal insulation, waterproofing, wind resistance, and noise reduction capabilities, have become the preferred roofing material for industrial plants, warehouse centers, large shopping malls, agricultural greenhouses, and other structures.

Integrated molding, efficiency doubled

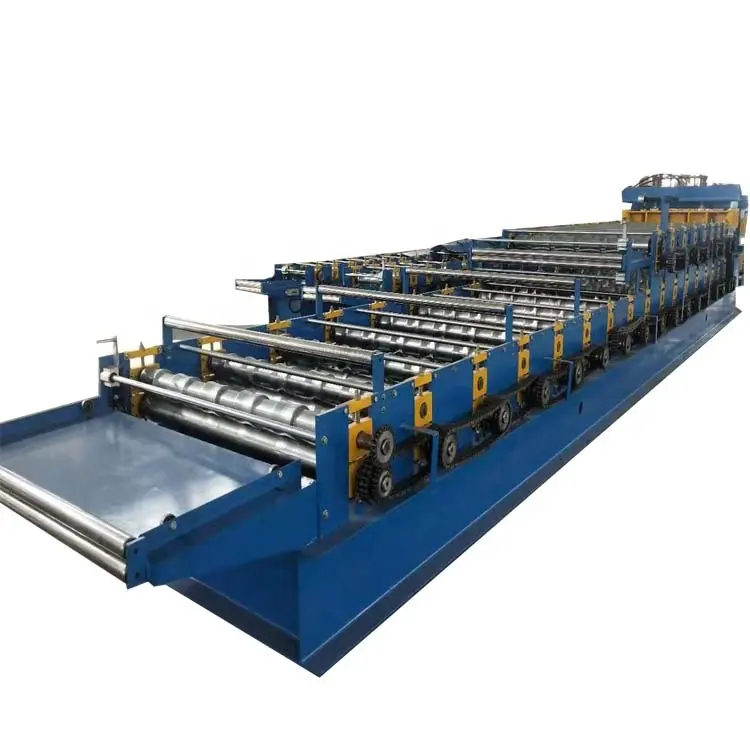

Our equipment features a “fully integrated process” design that eliminates traditional production barriers, achieving complete automation from raw material input to finished product output. The system integrates five core modules: dual unwinding machines, an automated adhesive coating system, precision lamination devices, rolling forming mechanisms, and an online cutting system, enabling fully automated production of double-layer roof panels without manual intervention. The dual unwinding machines can simultaneously handle two layers of different materials, with the servo feeding system ensuring ±0.2mm feeding accuracy for precise alignment. The automated adhesive coating system employs smart metering pumps, maintaining adhesive application error within ±0.3g/㎡ to ensure secure lamination while minimizing waste.

Precision control, superior quality

Precision is the cornerstone of double-layer roof panel quality. Our equipment achieves extreme precision in both hardware configuration and software control. The core rolling forming system employs imported alloy steel rollers precision-machined on a five-axis CNC machining center, with roller accuracy reaching 0.01mm. Integrated with Siemens PLC control systems and Panasonic servo motors, it enables real-time adjustment of rolling pressure and speed. This ensures the roof panels achieve perfectly shaped corrugations with wave curvature errors below 0.5mm/m, fully complying with international standards.

To address the critical aspects of double-layer composite manufacturing, the equipment features a dual-temperature control system and pressure sensors. These components precisely regulate temperature and pressure according to core material properties (e.g., EPS, PU, rock wool), ensuring tight adhesion between the composite layers and core materials. The peel strength exceeds 1.2N/mm, far surpassing the industry standard of 0.8N/mm. Additionally, an online quality inspection system continuously monitors the thickness, flatness, and composite strength of each meter of roof panel. Any detected anomalies trigger immediate shutdown and alarm, keeping the product defect rate below 0.1% to guarantee quality from the source.

Flexible adaptation to meet diverse needs

In response to the “multi-specification and personalized” demands of the construction market, our equipment boasts exceptional adaptability. The equipment supports processing of various materials such as 0.3-1.2mm thick color-coated steel plates, galvanized steel plates, and aluminum-magnesium-manganese alloy plates. It can produce double-layer roof panels with wave heights ranging from 25mm to 76mm and wave pitches from 120mm to 300mm. The length can be customized to any size between 0.5m and 12m according to customer needs, fully meeting the usage requirements of industrial, commercial, and agricultural buildings.

Modular mold design forms the core competitive edge of equipment adaptability. The system employs a rapid positioning device integrated with a hydraulic clamping system, enabling mold replacement within 30-45 minutes – a 90% reduction compared to traditional methods. Equipped with an intelligent touchscreen featuring over 100 standard production parameters, operators simply select the product model to automatically adjust settings, eliminating the need for technical expertise and significantly lowering operational barriers. Whether handling large-scale standard orders or small-batch customized requests, the equipment delivers efficient processing capabilities.

Global cases prove that quality wins trust

Our Double Layer Roof Sheet Roll Forming Machine has been exported to over 50 countries and regions worldwide, serving more than 300 roofing panel manufacturers. With its stable performance and superior quality, it has earned global recognition from customers.

Full-chain foreign trade services, cross-border cooperation worry-free

With over a decade of expertise in foreign trade, we are a trusted equipment supplier that deeply understands the challenges and needs of cross-border collaboration. We provide global clients with end-to-end services—from consultation to after-sales support—ensuring every partnership is hassle-free and secure.

During the pre-sales phase, we assembled a multilingual engineering team proficient in 12 languages including English, Russian, Spanish, and Arabic. Our experts conduct thorough market research on target markets, production scales, product specifications, and local construction standards to deliver customized equipment configurations, production process guidance, and ROI analysis reports. Additionally, we provide complimentary equipment demonstrations to enable clients to gain hands-on understanding of the equipment’s performance.

During the sales phase, we handle all export procedures for the equipment, including customs clearance, inspection, shipping/air freight bookings, and insurance, to ensure safe and timely delivery to the client’s facility. Upon arrival, our experienced engineers will provide on-site services, offering free installation, commissioning, operation training, and mold calibration until the client’s team fully masters the equipment. Additionally, we provide international certifications such as CE, ISO, and SGS to ensure compliance with target market regulations and smooth customs clearance.

During the after-sales phase, we provide instant technical support to customers through various channels such as hotlines, online videos, and emails. The core components of the equipment come with a 24-month warranty, during which damaged parts are replaced free of charge.

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.