技术变革与工业系统,我们致力于

为 Seds 的尊贵客户提供最佳和经济的解决方案。

Standing Seam Roll Forming Machine: Defining a New Paradigm for High-end Roof Production

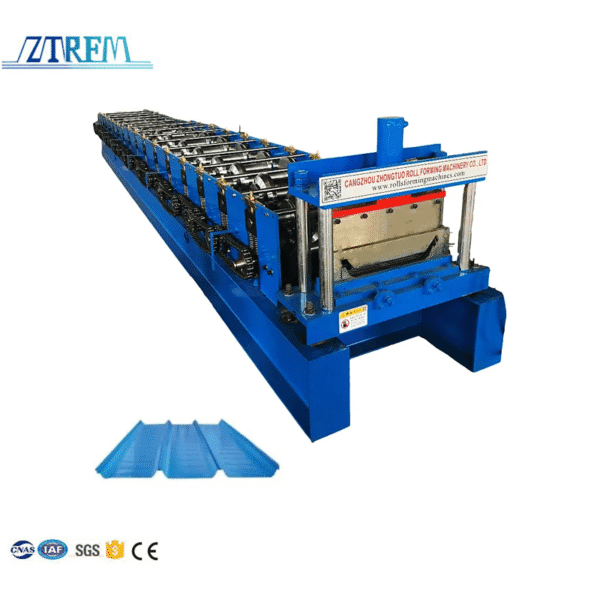

不同类型的冷弯成型机。我们是一家历史悠久的工厂,自 2006 年以来一直从事冷弯成型机的设计和制造。我们能生产的机器包括:屋面瓦成型机、CZ 檩条成型机、轻钢龙骨成型机、金属压花机、门系统成型机、天花板系统成型机、高频焊管机、分切生产线、定长切割生产线、货架系统成型机、地板装饰板成型机、彩石瓦生产线、热贴膜机等。

As buildings evolve beyond basic shelter functions, roofing systems have become a key metric for evaluating architectural quality, energy efficiency, and aesthetic value. In Europe, the low-carbon building movement is driving the integration of waterproofing and photovoltaic systems into roofing solutions. In North America, frequent extreme weather events are pushing roofing materials to withstand stronger wind and seismic forces. In Southeast Asia, the high-temperature and high-humidity climate imposes stringent requirements on roofing corrosion resistance and heat dissipation. The vertical seam roof system, with its seamless assembly, structural stability, and long service life, offers inherent advantages in these challenging environments.

The Structural Upgrade from “Fit” to “Fusion”

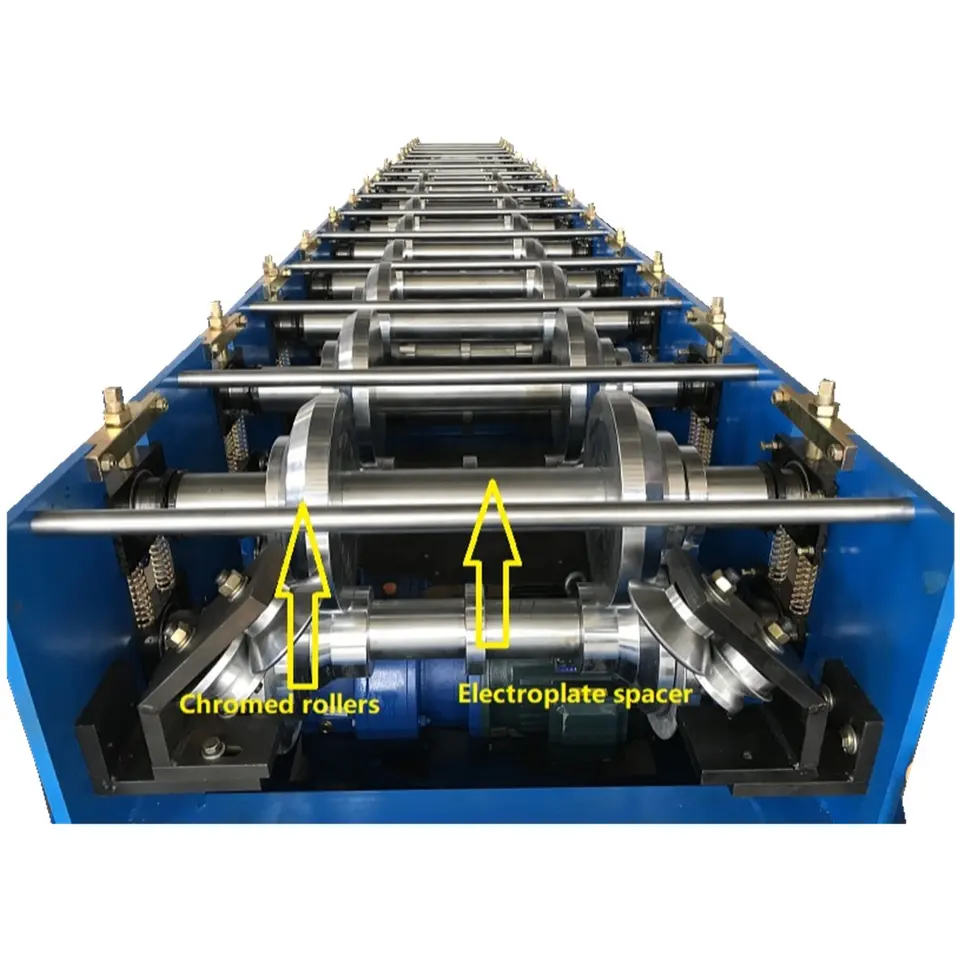

Waterproofing is the lifeblood of roofing, with edge locking being its core. Our forming machine has revolutionized traditional single-roll pressing by adopting an innovative ’20-stage progressive forming + 3-stage edge locking reinforcement’ process. Through CNC system precision control of pressure and angle for each roller set, the roof tile edge locking achieves dual protection through ‘mechanical interlocking + structural interlocking’.

In a Nordic ski resort project, the titanium-zinc composite roof tiles manufactured by this equipment not only withstand extreme cold (-30°C) and heavy snowfall, but their tightly sealed edges also prevent water leakage from melting snow, ensuring safe operation of indoor facilities.

One device handles all materials and all styles.

To meet the diverse needs of raw materials and patterns in the global market, our equipment has achieved dual breakthroughs in “full material compatibility + rapid pattern switching.” In terms of material adaptation, it can easily process various metal sheets such as 0.6-2.0mm thick galvanized steel, aluminum-manganese-manganese alloy, titanium-zinc plates, and copper without replacing core components. For pattern adjustment, parameters like edge locking height, sheet length, and corrugation shape can be set up through a touchscreen, complemented by a quick-change mold design.

Adapting to diverse global building needs

From the frigid Nordic regions to the scorching African deserts, from the humid Southeast Asia to the arid Middle East, our Standing Seam Roll Forming Machine produces roofing tiles that have successfully adapted to extreme environments and diverse construction scenarios worldwide.

In public architecture, this technology has become the go-to solution for landmark projects. A European football stadium’s roof tiles, manufactured with our equipment, not only meet the structural demands of large-span roofs but also feature photovoltaic modules on their smooth surfaces, achieving the low-carbon goal of “roof power generation.” At a Middle Eastern international airport, corrosion-resistant titanium-zinc sheets processed by our equipment effectively withstand local salt-alkali sand erosion, with an expected service life of 50 years.

This technology also demonstrates exceptional performance in residential and industrial applications. A premium villa community in North America utilizes color-coated vertical seam tiles manufactured with this system, combining aesthetic appeal with practical functionality. The tightly sealed seam structure ensures structural integrity even during hurricane seasons. In Southeast Asia, a food processing plant’s roof employs corrosion-resistant aluminum, magnesium, and manganese tiles, effectively preventing rust in high-temperature and high-humidity environments while maintaining hygienic safety standards for production facilities.

立缝机视频频道

为什么选择我们?

OEM/ODM 和定制一站式服务

全面的售后服务支持

提供 OEM、ODM

2.技术人员设计:绘制型材图和 3D 机器图

3.确定配置和生产

4.交货前测试

6.技术指导

7.售后服务:复杂机器的安装服务和定期客户回访

受到 95800 多家公司的信任

优质企业。通过与我们的合作,他们获得了

大力支持,实现了业务的突破和发展。