技术变革与工业系统,我们致力于

为 Seds 的尊贵客户提供最佳和经济的解决方案。

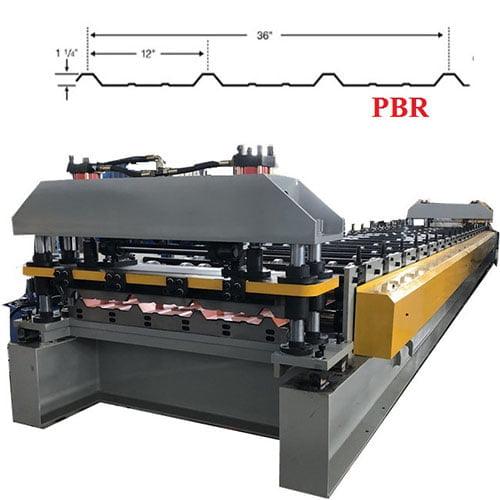

PBR panel, Max rib panel , Ag panel metal roofing sheet rolling forming machine

不同类型的冷弯成型机。我们是一家历史悠久的工厂,自 2006 年以来一直从事冷弯成型机的设计和制造。我们能生产的机器包括:屋面瓦成型机、CZ 檩条成型机、轻钢龙骨成型机、金属压花机、门系统成型机、天花板系统成型机、高频焊管机、分切生产线、定长切割生产线、货架系统成型机、地板装饰板成型机、彩石瓦生产线、热贴膜机等。

PBR panel, Max rib panel , Ag panel metal roofing sheet rolling forming machine

PBR panel, Max rib panel , Ag panel metal roofing sheet rolling forming machine is designed to make the metal roofing sheets in batch fully automatically. PBR panel, Max rib panel , Ag panel metal roofing sheet are quite popular in USA and South American. Here we will take those drawing profile for example to show you how our metal roofing sheet machine is designed.

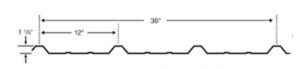

R-Panel roofing sheet

R-Panel is a multi-use wall and roof panel used primarily in pre-engineered metal building applications. R-Panel is also a popular choice for residential metal roofing, especially in the Southwest. An optional purlin bearing leg (PBR] rests on purlins and provides support for fastening the panel lap

.

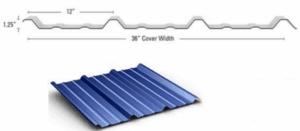

Max- Rib Panel roofing sheet

Max: Rib is a low profile (3/4″) panel that is equally well suited for residential roofing and post frame applications.

Varying applications, end uses, and expectations require different metal panel alternatives. Fortunately, Zhongtuo

popular Max-Rib profile is available in five distinct options: Max-Rib UItra, Max Rib I, Max-Rib 100, and Max-Rib

Commodity/Liner. The best choice for your individual project depends on factors such as performance, desired

longevity, and budget.

The PBR metal roof profile:

The PBR metal roof and wall panel is a high-quality, versatile option. They can be easily installed both horizontally and vertically, ensuring a functional design that meets the requirements of your customers’ building projects.

PBR panel, Max rib panel , Ag panel metal roofing sheet rolling forming machine:

| Machine frame | 350mm H beam structure, with 20mm welded steel middle support plate. |

| Material of rollers

| High grade 45# forged steel |

| Chromed treatment (Chrome thickness:0.05 mm), make the rollers surface more smoothly, improve the hardness and prevent abrasion, anti corrosion increase of service life | |

| Forming stations

| Upper layer 18 roller station |

| Rolling type: separate rolling design concept, it can release internal stress from the sheets, then the sheet will be in good shape and high precision. | |

| Diameter of shafts | Φ80mm solid |

| Material of shafts | High grade 45#,with heat treatment |

| Forming speed | 0-25m/min |

| voltage | 380V/50HZ/3P (as requested) |

| Transmission way | By 1 inch chain |

| Main motor | 7.5KW |

| Cutting blade material | Gcr12 quenched treatment |

| Cutting type | hydraulic post cutting |

| Driving method | By pillar type Cylinder |

And if you like to add the cut to length function, we can also add for you. The cut to length could be together with the PLC and help you cut the coil to pieces and then use for ridge cap or gutters bending profile.

Machine base frame

1.There are diagonal brace in the machine base frame,which can make the machine frame more stable and stronger.

2.After the whole welding, vibration is used to weld the stress. After large-scale planer machining, the horizontal and rigidity of the frame are ensured.

3.Hand wheels on both sides can be used to adjust the feeding width.

4.Four stainless rollers can make the material go into the machine smoothly and prevent the scratch on the material surface.

5.There are three rows of orange plastic rollers can make the steel coil go into the machine smoothly.

As to the decoiler and stacker, you can choose the manual one or hydraulic one according to your requirements

| Machine frame | 350mm H beam structure, with 20mm welded steel middle support plate. |

| Material of rollers

| High grade 45# forged steel |

| Chromed treatment (Chrome thickness:0.05 mm), make the rollers surface more smoothly, improve the hardness and prevent abrasion, anti corrosion increase of service life | |

| Forming stations

| Upper layer 18 roller station |

| Rolling type: separate rolling design concept, it can release internal stress from the sheets, then the sheet will be in good shape and high precision. | |

| Diameter of shafts | Φ80mm solid |

| Material of shafts | High grade 45#,with heat treatment |

| Forming speed | 0-25m/min |

| voltage | 380V/50HZ/3P (as requested) |

| Transmission way | By 1 inch chain |

| Main motor | 7.5KW |

| Cutting blade material | Gcr12 quenched treatment |

| Cutting type | hydraulic post cutting |

| Driving method | By pillar type Cylinder |

为什么选择我们?

OEM/ODM 和定制一站式服务

全面的售后服务支持

提供 OEM、ODM

2.技术人员设计:绘制型材图和 3D 机器图

3.确定配置和生产

4.交货前测试

6.技术指导

7.售后服务:复杂机器的安装服务和定期客户回访

受到 95800 多家公司的信任

优质企业。通过与我们的合作,他们获得了

大力支持,实现了业务的突破和发展。