技术变革与工业系统,我们致力于

为 Seds 的尊贵客户提供最佳和经济的解决方案。

High-Performance Trapezoidal Roof Panel Roll Forming Machine: Shaping High-Quality Building Envelopes Globally

不同类型的冷弯成型机。我们是一家历史悠久的工厂,自 2006 年以来一直从事冷弯成型机的设计和制造。我们能生产的机器包括:屋面瓦成型机、CZ 檩条成型机、轻钢龙骨成型机、金属压花机、门系统成型机、天花板系统成型机、高频焊管机、分切生产线、定长切割生产线、货架系统成型机、地板装饰板成型机、彩石瓦生产线、热贴膜机等。

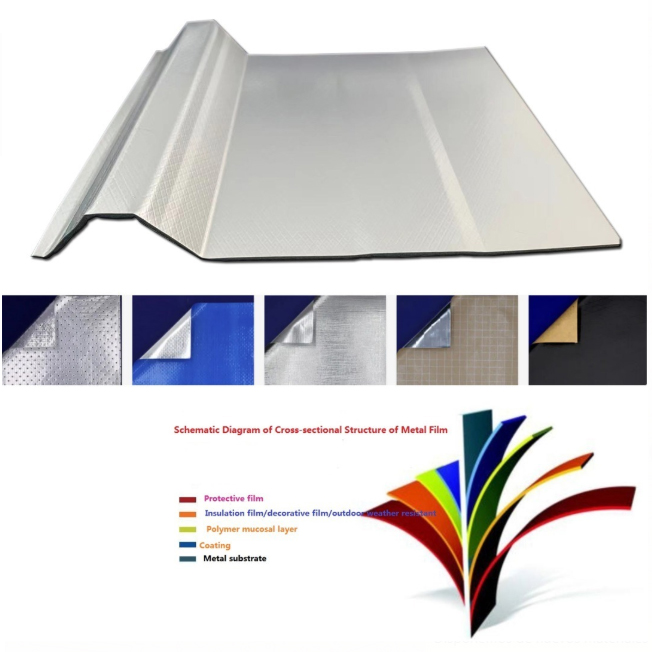

With the acceleration of global urbanization and the continuous upgrading of the construction industry, the demand for high-quality, energy-saving and durable building envelope materials is growing rapidly. Trapezoidal roof panels, with their excellent load-bearing capacity, waterproof performance, and cost-effectiveness, have become the preferred choice for roof systems in industrial plants, warehouses, logistics centers, and large public buildings.

The popularity of trapezoidal roof panels is driven by multiple factors. On one hand, countries around the world have successively introduced strict building energy efficiency and safety standards. Trapezoidal roof panels, with their lightweight and high-strength characteristics, can effectively reduce the building’s self-weight while ensuring structural safety, and their good thermal insulation and sound insulation performance help improve the energy efficiency of buildings. On the other hand, in the context of the global pursuit of sustainable development, trapezoidal roof panels made of metal materials are 100% recyclable, in line with the concept of green building, and are widely favored by developers and construction enterprises.

As the core equipment for the production of trapezoidal roof panels, the trapezoidal roof panel roll forming machine plays a decisive role in the quality, efficiency and cost of roof panel production. A high-performance forming machine can not only ensure the dimensional accuracy and structural stability of trapezoidal roof panels, but also improve production efficiency and reduce production costs, helping enterprises gain a competitive advantage in the fierce market competition. It can be said that the advanced level of trapezoidal roof panel roll forming machines directly affects the development quality of the global metal roof panel industry.

Trapezoidal Roof Panel Roll Forming Machine: Core Equipment for High-Quality Roof Panel Production

Trapezoidal roof panels are known for their unique trapezoidal cross-sectional structure, which gives them excellent mechanical properties and waterproof effects. The trapezoidal roof panel roll forming machine is the key equipment to realize the precise forming of this structure. It is like a “precision craftsman” in the metal processing industry, transforming flat metal coils into high-quality trapezoidal roof panels through continuous and precise rolling, providing a solid guarantee for the construction of high-quality building roof systems.

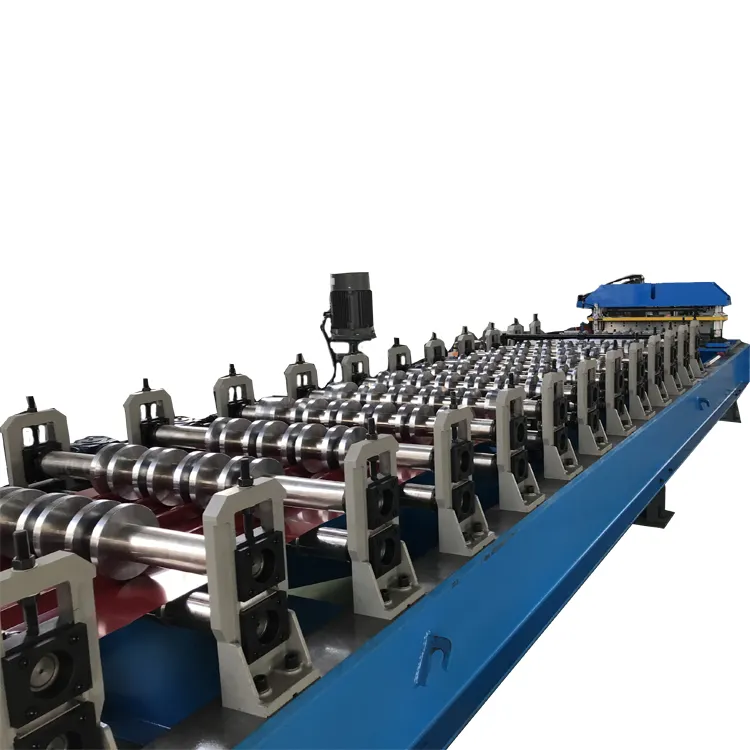

The working principle of the trapezoidal roof panel roll forming machine is based on the advanced cold roll forming technology. The metal coil is uncoiled by the uncoiler first, and then flattened by the leveling device to eliminate the internal stress of the metal sheet and ensure the flatness of the raw material. Then, under the drive of the transmission system, the metal sheet enters the forming unit, and is gradually bent and formed through multiple sets of precision forming rollers arranged in sequence, and finally forms the trapezoidal cross-sectional shape preset by the design. After forming, the roof panel is cut to length by the automatic cutting device according to the required size, and finally the finished product is output and stacked.

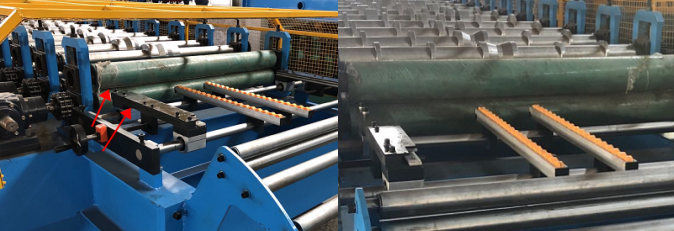

A high-quality trapezoidal roof panel roll forming machine is composed of multiple core components that work closely together. The uncoiler, as the starting link of the production line, adopts a hydraulic expansion structure, which can adapt to metal coils of different diameters and ensure stable uncoiling. The leveling device is equipped with high-precision leveling rollers, which can effectively correct the warpage and unevenness of the metal sheet, ensuring the flatness of the roof panel surface. The forming unit is the core part of the equipment, and the forming rollers are made of high-quality alloy steel,经过 precision machining and heat treatment, with high hardness and wear resistance, ensuring the dimensional accuracy of the trapezoidal roof panel during long-term production. The transmission system adopts a frequency conversion speed regulation mechanism, which can realize stepless speed regulation according to the production needs, ensuring the stability and consistency of the forming process. The automatic cutting device adopts high-precision servo positioning technology, which can realize precise cutting of roof panels of different lengths, with a cutting error of less than ±1mm.

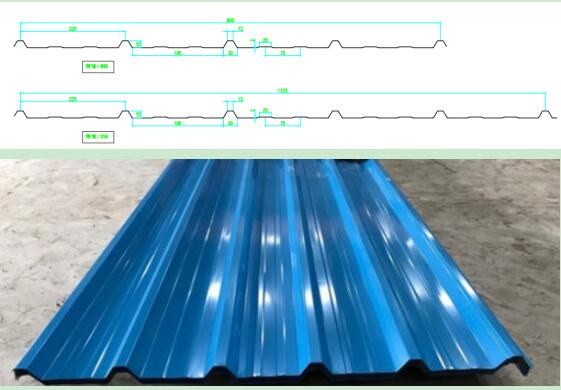

Our trapezoidal roof panel roll forming machine can produce trapezoidal roof panels of various specifications according to customer needs. The height of the trapezoidal cross-section can be adjusted between 25mm-75mm, the width of the panel can be customized between 500mm-1200mm, and the thickness of the metal sheet can be processed from 0.3mm-1.2mm. It can process various metal materials such as galvanized steel, color-coated steel, aluminum alloy, etc., to meet the different requirements of various construction projects for roof panels.

Outstanding Performance, Distinct Competitive Advantages

Our company’s trapezoidal roof panel roll forming machine has won wide recognition from customers around the world with its outstanding performance and reliable quality. Compared with similar products on the market, it has obvious competitive advantages, providing efficient and high-quality production solutions for metal roof panel manufacturers.

(1) High-Precision Forming, Stable Quality

The dimensional accuracy of trapezoidal roof panels directly affects the installation effect and waterproof performance of the roof system. Our trapezoidal roof panel roll forming machine adopts a high-precision CNC control system and imported forming rollers, which can accurately control the geometric dimensions of the trapezoidal roof panel. The parallelism error of the trapezoidal cross-section is less than 0.3mm/m, the height error is within ±0.2mm, and the surface of the formed roof panel is smooth and free of wrinkles, indentations and other defects. This high-precision forming effect ensures that the roof panels can be closely fitted during installation, effectively avoiding water leakage problems caused by installation gaps, and improving the overall quality and service life of the roof system.

(2) High-Efficiency Production, Cost Saving

In the context of the increasing cost of labor and raw materials, improving production efficiency is the key for enterprises to reduce costs and increase efficiency. Our trapezoidal roof panel roll forming machine adopts a fully automatic production line design, which can realize the integrated operation of uncoiling, leveling, forming, cutting and stacking, with a maximum production speed of 20-30 meters per minute, which is 30%-60% higher than that of traditional forming equipment. For a manufacturer with an annual output of 1 million square meters of trapezoidal roof panels, using our equipment can save about 3,000 hours of production time every year, reduce labor costs by more than 20%, and significantly improve the economic benefits of the enterprise.

(3) Wide Applicability, Diversified Customization

Different construction projects have different requirements for the specifications, materials and performance of trapezoidal roof panels. Our trapezoidal roof panel roll forming machine has strong adaptability and can meet the diversified customization needs of customers. In terms of specifications, it can produce trapezoidal roof panels of different heights, widths and thicknesses by replacing the forming rollers and adjusting the control parameters. In terms of materials, it can process various metal materials such as galvanized steel, color-coated steel, aluminum alloy, and stainless steel. In addition, we can also customize special forming machines according to the special requirements of customers, such as roof panels with enhanced waterproof structures, thermal insulation composite roof panels, etc., to provide customers with one-stop production solutions.

(4) Stable and Reliable, Low Maintenance Cost

The stable operation of equipment is the guarantee of continuous production. Our trapezoidal roof panel roll forming machine adopts high-quality components and advanced manufacturing processes, and has undergone strict quality testing and fatigue testing before leaving the factory. The key components such as forming rollers, bearings and motors are all from well-known international brands, ensuring the stability and reliability of the equipment. The average trouble-free operation time of the equipment can reach more than 10,000 hours. At the same time, the equipment is equipped with a complete fault diagnosis system, which can real-time monitor the operating status of the equipment, timely alarm and prompt when a fault occurs, and facilitate maintenance personnel to quickly locate and solve the problem. The maintenance cost of the equipment is 25%-35% lower than that of similar products, greatly reducing the production cost of enterprises.

为什么选择我们?

OEM/ODM 和定制一站式服务

全面的售后服务支持

提供 OEM、ODM

2.技术人员设计:绘制型材图和 3D 机器图

3.确定配置和生产

4.交货前测试

6.技术指导

7.售后服务:复杂机器的安装服务和定期客户回访

受到 95800 多家公司的信任

优质企业。通过与我们的合作,他们获得了

大力支持,实现了业务的突破和发展。