The demand for ceiling systems in modern construction and decoration industries continues to grow, and T-shaped steel, as the core component of the ceiling system, has a direct impact on the cost and effect of the project due to its manufacturing efficiency and quality. In order to meet the market’s dual demand for main T-shaped steel and auxiliary T-shaped steel, a flexible T-shaped steel forming machine came into being.

T-shaped steel forming machine is an advanced equipment specially used to produce metal components required for ceiling systems. This equipment can not only produce main T-shaped steel, but also auxiliary T-shaped steel, and achieves the versatility and high precision of the equipment through an integrated design.

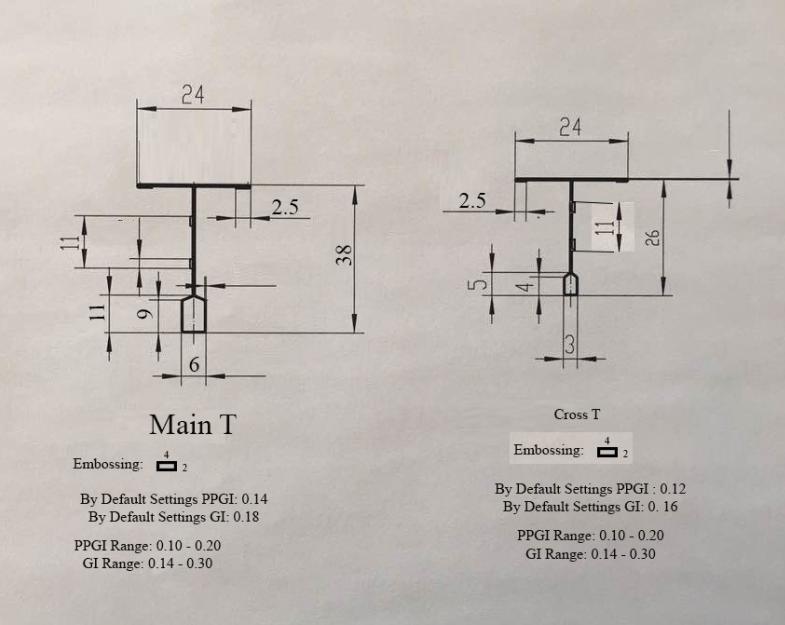

The difference between main T-shaped steel and auxiliary T-shaped steel

Main T-shaped steel: As the main load-bearing component of the ceiling grid, it usually runs through the entire length of the room. It is mainly responsible for supporting the weight of the entire ceiling system, usually with a length of 3.6 meters.

Auxiliary T-shaped steel: used to connect the main T-shaped steel to form a fine ceiling grid, usually with two specifications, 0.6 meters and 1.2 meters.

Features and advantages of T-shaped steel forming machine

One machine for multiple uses: Through simple adjustment, the switching production of main T-shaped steel and auxiliary T-shaped steel can be achieved.

The main T-shaped steel passes through the equipment’s No. 18 and No. 19 rolling mills to form a core notch.

Adjust the gap between the upper and lower rollers so that there is no notch when the metal strip passes through the rolling mill, and the flat T-shaped steel can be produced.

Efficient production:

The production length of the main T-shaped steel is 3.6 meters, and one piece is completed at a time.

The length of the auxiliary T-shaped steel is 0.6 meters or 1.2 meters, 0.6 meters The specification produces 2 pieces at a time, and the specification of 1.2 meters produces 1 piece at a time.

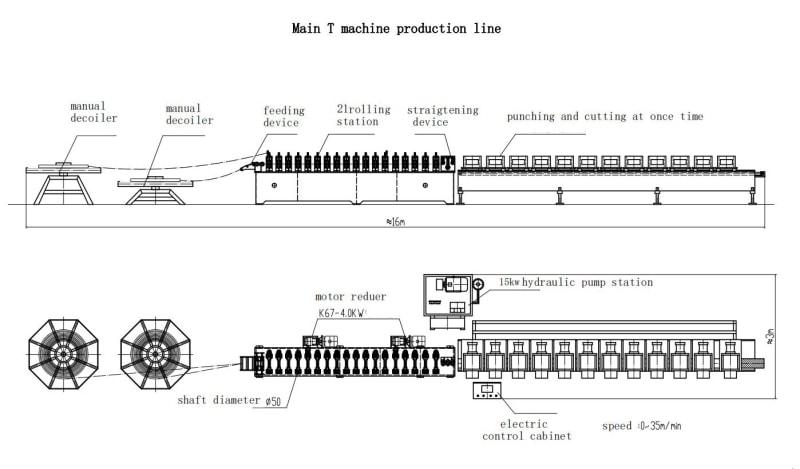

High-speed operation: The main T-shaped steel can be formed at a speed of up to 35 meters/minute, and the auxiliary T-shaped steel can reach a speed of 25 meters/minute, which greatly improves production efficiency.

Combined process: The equipment integrates punching and cutting functions, and completes these two processes in one operation, ensuring accurate dimensions and reducing manual intervention.

Flexibility and stability: The equipment adopts a modular design, and can produce products of different specifications by adjusting the number and pressure of rolling mills.

Innovation and practical application of the equipment

This equipment has a total of 21 rolling mills. The specially designed No. 18 and No. 19 rolling mills can flexibly adjust the gap to meet the needs of different specifications of T-shaped steel. The process flexibility enables the equipment to quickly switch to produce products of different models and specifications, which is not only suitable for large-scale production, but also can meet personalized customization needs.