In the modern construction industry, floor deck machine, as a key equipment, is widely used in the production of steel structure floor deck. Its main functions include automatic unwinding and feeding, forming and cutting, conveying code segments, etc., and it has gradually developed from traditional production methods to modernization. Today, we will introduce several floor deck machines suitable for different market needs in detail, including models customized for the Brazilian and Saudi markets, to give you a deep understanding of its evolution, characteristics and technical advantages.

I. Evolution of floor deck machine

The design and function of floor deck machine have undergone a transformation from traditional to modern. Zhongtuo’s floor deck machine has a production history of many years in China, and has been gradually updated and iterated, from the early traditional overlap type to the hidden type, dovetail type, and then to the inverted dovetail type and cast-free type. The diversity and functionality of the equipment have been greatly improved.

- Traditional overlap type: Early floor deck machines were mostly overlap structures, with a relatively simple production method, mainly relying on manual operation and relatively inefficient automation equipment.

- Hidden and dovetail: With the advancement of technology, floor deck machines have gradually introduced hidden and dovetail designs, which can effectively reduce material waste and improve production efficiency.

- Inverted dovetail and cast-free: In recent years, inverted dovetail and cast-free floor deck machines have become a new trend in the industry. While ensuring production efficiency, these equipment can also reduce the post-processing process in construction, which meets the needs of modern buildings.

This evolution not only improves the production capacity of floor deck machines, but also improves the applicability of products, which can meet the needs of different markets and different customers. For example, these floor deck machines have been widely used in many countries such as the United States, Canada, Italy, and Brazil.

II. Uncoiler: Automated operation ensures high-speed production

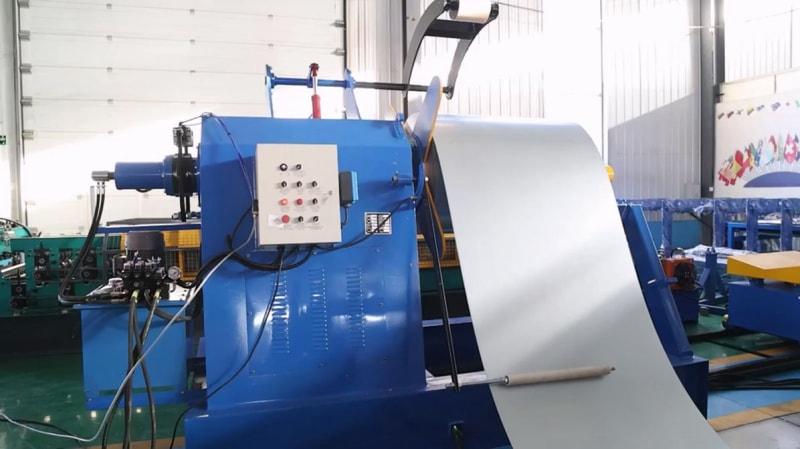

In the workflow of the floor deck machine, the uncoiler plays an important role. It is responsible for automatically uncoiling and feeding the raw steel coil to ensure the continuity and stability of the production process. Zhongtuo’s uncoiler has an automatic start and stop function, which can adjust the feeding direction (left or right feeding) according to actual needs, greatly improving the flexibility of operation.

In addition, the unwinding machine is also equipped with a material pressing device, which can effectively prevent the steel coil from being fluffy and open during the unwinding process, ensuring the stability of the material and continuous feeding.

III. Forming machine: high-speed operation ensures production quality

The forming machine is an important part of the floor decking machine. It is responsible for rolling the steel plate into the required floor decking shape. Zhongtuo’s forming machine adopts advanced wall panel structure and discharge structure design, equipped with a double-row chain system and an integral forged sprocket to ensure low wear performance in long-term operation.

In order to ensure production efficiency, the forming machine also adopts dual 15-kilowatt motors and hard-toothed gearbox transmission system, so that the equipment can operate at a high speed of 25 meters per minute. At the same time, the structural design of the equipment is compact, which can ensure the stability and durability of the equipment while maintaining a high rate.

IV. Cutter system: accurate cutting reduces waste

The cutter system is an indispensable part of the floor decking machine production, responsible for cutting the formed floor decking into the required length. Zhongtuo’s floor deck machine is equipped with a double-cylinder and double-edged knife cutting system with a blade thickness of 12 mm, which can ensure material waste during the cutting process.

The design of the cutting system ensures that the blade is evenly stressed, and the blade is embedded in the blade beam, which improves the service life of the equipment. In addition, the stability and accuracy of the system also provide a strong guarantee for the dimensional accuracy of floor deck production.

V. Electric control system: a combination of stability and remote operation and maintenance

Modern floor deck machines are inseparable from the support of intelligent electric control systems. Zhongtuo’s floor deck machine uses Siemens electric control system and Schneider low-voltage electrical appliances, which can effectively ensure the operating stability and dimensional accuracy of the equipment. Through the electric control system, the production line can be debugged in a short time, avoiding errors in manual operation.

The equipment also has remote operation and maintenance functions. Through the remote control system, operators can monitor the equipment status, fault warning and remote adjustment, which greatly reduces the need for on-site maintenance and improves production safety.

With the continuous advancement of floor deck machine technology, its application in the global market has gradually expanded to meet the needs of different countries and regions. Whether in the diversified design of equipment or in automation and intelligent control, the floor deck machine has demonstrated strong technical advantages. With its many years of experience, Zhongtuo Company is committed to providing customers with high-quality equipment solutions to help customers gain an advantage in the fierce market competition.

With the development of the global construction industry and the acceleration of modernization, the floor deck machine will continue to play an important role, and with the further improvement of technology, it will promote the steel structure industry to develop in a more intelligent direction.