As soon as the New Year bell of 2025 rang, Zhongtuo Cold Bending rushed out on the industry track with an enthusiastic attitude and created brilliant achievements again! At the beginning of this new era, Zhongtuo Cold Bending has become a dazzling star in the field of cold bending equipment manufacturing, and continues to emit dazzling light.

Looking back on the past period of time, Zhongtuo Cold Bending’s orders have come from all over the world like snowflakes. The #color steel tile machine and #floor decking machine orders from the United States are undoubtedly a high recognition of Zhongtuo Cold Bending’s strong technical strength by the North American market. Every piece of equipment sent to the United States carries the wisdom and sweat of Zhongtuo Cold Bending people. The order for the keel machine in Vietnam is like a powerful signal, indicating that Zhongtuo Cold Bending’s influence in the Southeast Asian market is steadily expanding.

In Southeast Asia, Zhongtuo Cold Bending’s equipment has won the trust and praise of customers with its stable performance and service. The variable-section villa keel machine order from Albania is of special significance, which fully demonstrates the unique charm of Zhongtuo Cold Bending in the niche market in Europe.

In the face of the special needs of the niche market, Zhongtuo Cold Bending has successfully created products that meet local needs with its superb technology and innovative ideas, opening up a broader market space for the company. The CZ steel machine order from India is undoubtedly a strong proof of Zhongtuo Cold Bending’s technical adaptability in the South Asian market. In the complex market environment of South Asia, Zhongtuo Cold Bending has met the needs of Indian customers by continuously optimizing its technology, further consolidating its market position in South Asia.

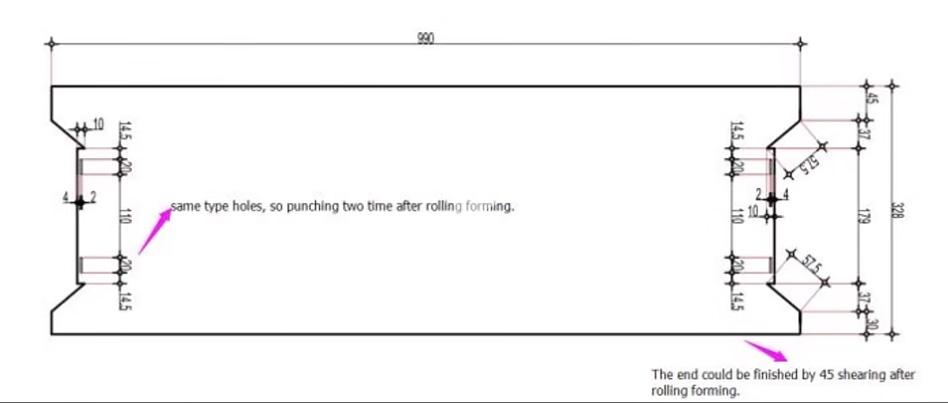

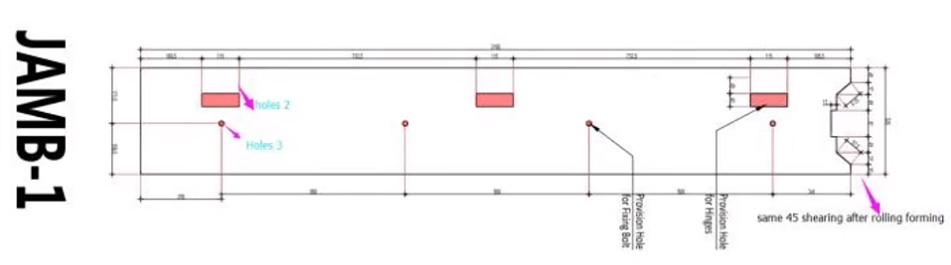

Today is destined to be recorded in the history of Zhongtuo Cold Bending. European metal door manufacturers – customers from Spain resolutely chose Zhongtuo Cold Bending’s #doorframe forming machine. Behind this order is in-depth and meticulous communication between the two parties. During the communication process, the customer raised many key technical issues regarding the door frame forming machine. The requirement of seamless door frame docking is like an insurmountable mountain, which poses a severe challenge to Zhongtuo Cold Bending’s mechanical manufacturing capabilities. However, the technical team of Zhongtuo Cold Bending has provided a satisfactory solution with its deep technical accumulation and rich experience. No dezincification during the forming process is the basic requirement for Zhongtuo Cold Bending to control the cold bending forming process.

Zhongtuo Cold Bending ensures that there will be no dezincification during the forming process by continuously optimizing the process flow and strictly controlling the production links. No deformation during hydraulic shearing, this requirement reflects the customer’s high attention to mechanical stress and structural design. Zhongtuo Cold Bending’s ability in this regard ensures the stability of the product during hydraulic shearing through carefully designed structural stress calculations. High-speed production without stopping, this requirement is a concentrated test of the overall equipment stability and intelligent control of Zhongtuo Cold Bending. Zhongtuo Cold Bending ensures the stable operation of the equipment during high-speed production by adopting advanced intelligent control systems and high-quality components. In response to these issues, the technical team of Zhongtuo Cold Bending gave convincing responses to customers, demonstrating strong technical strength and professionalism.

Not only that, Zhongtuo Cold Bending also actively demonstrated its significant advantages in the field of intelligence to customers. The access to Siemens Cloud makes equipment operation and maintenance more intelligent. Through the Siemens cloud platform, all operating data of the equipment can be uploaded to the cloud in real time, and technicians can monitor and manage the equipment anytime and anywhere. The remote operation and maintenance function is like equipping the equipment with a dedicated doctor who is always on call. No matter where the equipment is, technicians can diagnose and solve problems with the equipment in a timely manner through remote operation. The data neuron early warning system is like the “clairvoyance” and “wind hearing” of the equipment, which can keenly capture subtle anomalies in the operation of the equipment. Once an abnormal situation is found, the system will immediately issue an early warning, allowing technicians to take measures in a very short time to prevent it. The remote input function improves the convenience and flexibility of operation. Operators do not need to be on site in person, but can easily complete the operation of the equipment by remote input commands. The display of these intelligent functions has given Spanish customers a deeper understanding of Zhongtuo Cold Bending’s products, and further strengthened their determination to choose Zhongtuo Cold Bending.

Looking forward to the new year, Zhongtuo Cold Bending will always adhere to the concept of scientific and technological innovation and take technology and service as the wings of corporate development. In the field of global cold-bending equipment manufacturing, Zhongtuo Cold Bending will continue to forge ahead, constantly write new legendary chapters, and contribute its own strength to promoting the development of the industry.