Introduction to Roll Forming Technology

In the world of industrial manufacturing, efficiency and precision are not just desirable qualities—they are essential components for success and profitability. Among the many metal forming technologies available today, roll forming stands out as an exceptionally versatile and efficient process that has revolutionized the production of continuous cross-sectional profiles from various metal materials. This sophisticated technology has become the backbone of numerous industries, including construction, automotive, aerospace, and consumer goods, enabling the mass production of complex profiles with remarkable consistency and minimal material waste.

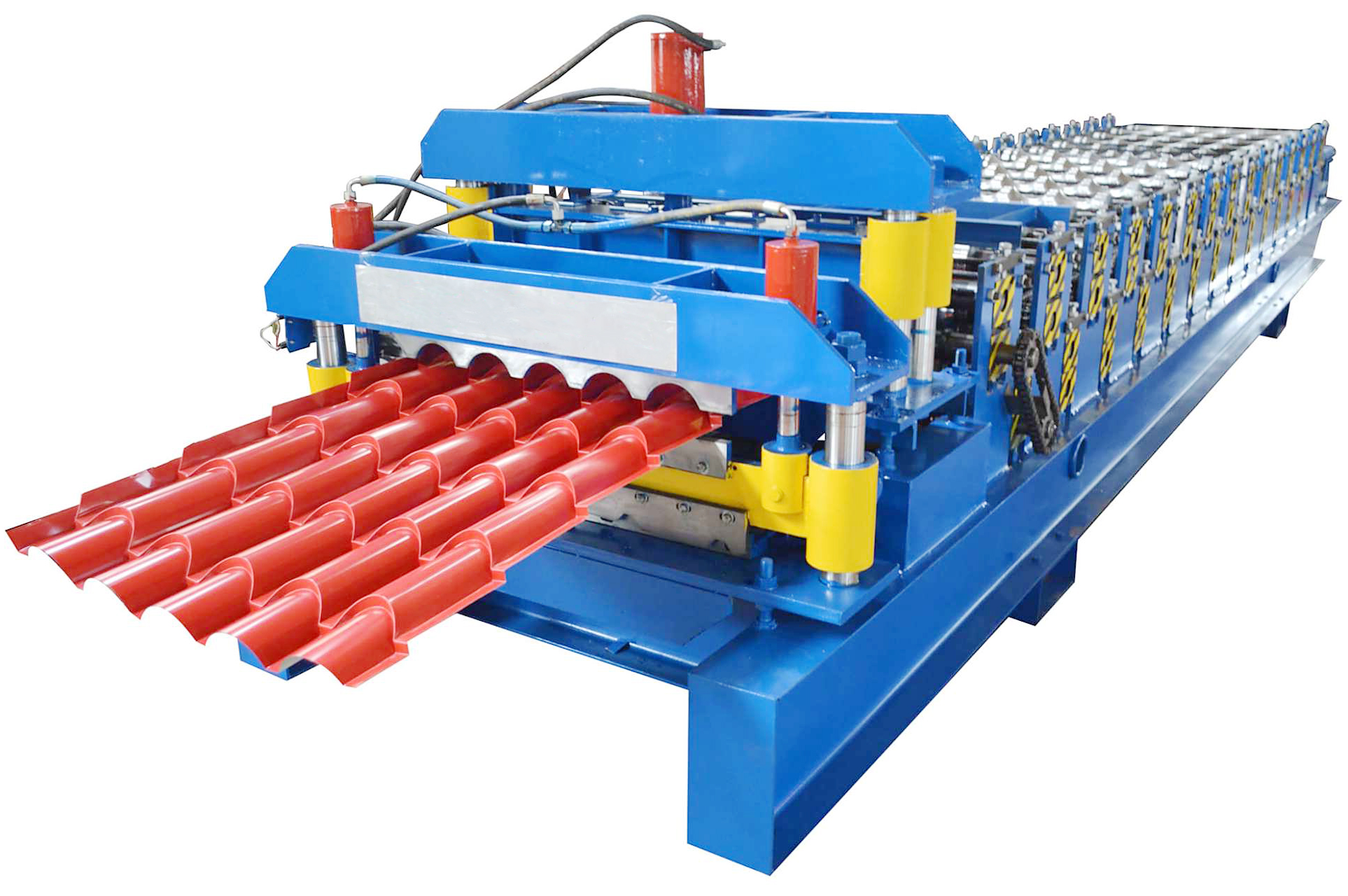

At its core, roll forming is a continuous bending operation where sheet metal or strip material passes through consecutive sets of rolls, each performing an incremental part of the bend until the desired cross-sectional profile is achieved. Unlike press braking, which forms the entire profile in a single operation, roll forming distributes the forming process across multiple stations, resulting in superior surface quality, enhanced mechanical properties, and higher production speeds. This comprehensive guide explores the technological advancements, applications, and selection criteria for modern roll forming systems, with particular emphasis on how companies like Zhongtuo Machine are pushing the boundaries of what’s possible in metal forming technology.

The Evolution and Working Principle of Roll Forming Machines

From Basic Forming to Sophisticated Manufacturing Systems

The concept of roll forming dates back centuries, with early implementations focused on simple profiles for basic applications. Today’s roll forming machines represent the culmination of decades of innovation, integrating computer-controlled systems, advanced materials, and sophisticated engineering principles to achieve unprecedented levels of precision and efficiency. Modern roll forming equipment has evolved from standalone forming units to complete manufacturing systems that incorporate pre-punching, notching, embossing, cutting, and automated material handling capabilities.

Contemporary roll forming lines, such as those developed by Zhongtuo Machine, exemplify this technological evolution. These systems combine precision mechanical components with sophisticated control systems to deliver consistent, high-quality profiles at production speeds that can exceed 200 feet per minute, depending on material complexity and thickness. The integration of Industry 4.0 principles, including IoT connectivity, real-time monitoring, and predictive maintenance capabilities, has further enhanced the reliability and efficiency of these manufacturing workhorses.

The Fundamental Operating Principle

Roll forming operates on a straightforward yet highly effective principle: gradual, incremental deformation. The process begins with a coiled metal strip that is fed into the roll forming machine. As the material progresses through the system, it passes through multiple pairs of forming rolls arranged in successive stations. Each station progressively bends the metal a few degrees at a time until the final cross-section is achieved at the last station.

This incremental approach offers significant advantages over alternative forming methods:

- Superior Surface Quality: By avoiding sudden, drastic deformation, roll forming prevents surface marring and minimizes residual stresses.

- Enhanced Mechanical Properties: The cold working process can improve the strength and hardness of the formed material through work hardening.

- Exceptional Consistency: The continuous nature of the process ensures minimal variation between different sections of the same production run.

- Material Efficiency: Roll forming typically generates less scrap than competing processes, especially when compared to press braking of complex profiles.

Advanced Applications Across Industries

Construction and Building Materials

The construction industry represents one of the largest application areas for roll forming technology. The ability to produce long, consistent structural components with complex cross-sections makes roll forming ideal for manufacturing building materials. Modern roll forming machines, like Zhongtuo’s advanced systems, produce a diverse range of construction components, including structural framing members, roof and wall panels, ceiling grids, and structural studs. The technology’s versatility extends to specialized applications such as sigma purlins for industrial buildings, custom flashings, and trim components that require both aesthetic appeal and functional performance.

Recent advancements have expanded the capabilities of roll forming in construction applications. The development of high-strength steel alloys and corrosion-resistant coatings has enabled the production of lighter, more durable building components. Meanwhile, sophisticated roll tooling designs allow for the integration of multiple features into a single profile, reducing assembly time and improving structural integrity. These innovations have positioned roll forming as the manufacturing method of choice for many construction applications, particularly in pre-engineered building systems where consistency and precision are paramount.

Aerospace and Automotive Innovations

The aerospace and automotive industries demand exceptionally high standards for component precision, strength, and weight efficiency. Roll forming technology has risen to meet these challenges, enabling the production of complex profiles from advanced materials, including high-strength aluminum alloys, titanium, and specialized composites. In aerospace applications, roll-formed components are found in airframe structures, wing stringers, and interior support systems where consistent cross-sections and reliable mechanical properties are essential for safety and performance.

The automotive sector has embraced roll forming for numerous applications, including seat frames, bumpers, roof rails, door beams, and structural reinforcements. The industry’s shift toward electric vehicles has further increased demand for roll-formed battery enclosure components and specialized structural members. Research into advanced aluminum-lithium alloys has demonstrated significant potential for aerospace applications, with optimized rolling strategies achieving strength isotropy synergy—reducing anisotropy by over 20% in yield strength and 50% in elongation while maintaining high strength levels: cite[8]. These material advances, combined with precision roll forming capabilities, are enabling lighter, stronger, and more fuel-efficient vehicles across the transportation sector.

Specialized Industrial Applications

Beyond construction and transportation, roll forming technology serves numerous specialized industrial applications. The solar energy sector relies on roll forming to produce mounting structures for photovoltaic panels, with specialized machines capable of creating complex profiles that accommodate various panel configurations and installation requirements. Similarly, the storage industry utilizes roll forming for manufacturing pallet rack components, shelving systems, and specialized storage solutions that require both strength and dimensional accuracy.

Other industrial applications include roll forming for HVAC duct systems, electrical raceways, furniture components, and consumer products. The flexibility of modern roll forming systems allows manufacturers to quickly switch between different profiles, making the technology economically viable for both high-volume production and specialized custom applications. This adaptability has become increasingly valuable as markets demand greater product variety and faster time-to-market for new designs.

Technological Advancements in Modern Roll Forming Systems

Digitalization and Industry 4.0 Integration

The digital transformation of manufacturing has profoundly impacted roll forming technology, with modern systems incorporating sophisticated control systems, connectivity features, and data analytics capabilities. Contemporary roll forming machines increasingly feature PLC-based control systems that manage every aspect of the forming process, from material feeding and roll positioning to cutting and post-forming operations. These control systems enable precise parameter management, ensuring consistent quality throughout production runs and simplifying operation through intuitive human-machine interfaces.

The integration of Industry 4.0 concepts represents the cutting edge of roll forming technology. Zhongtuo Machine and other industry leaders now offer systems equipped with IoT connectivity, enabling real-time monitoring of production parameters, remote diagnostics, and predictive maintenance capabilities. These innovative manufacturing features can significantly reduce downtime by identifying potential issues before they result in production interruptions. Additionally, the data collected from connected systems provides valuable insights for process optimization, quality improvement, and maintenance planning, ultimately enhancing overall equipment effectiveness and return on investment.

Precision Engineering and Advanced Control Systems

Modern roll forming machines incorporate numerous engineering innovations that enhance precision, reliability, and versatility. High-precision gearboxes, servo-driven positioning systems, and advanced guide technologies work in concert to maintain tight tolerances throughout extended production runs. Today’s systems can process material thicknesses from as thin as 0.3 mm for delicate applications up to 5 mm or more for structural components: cite[1], with tolerances routinely measured in hundredths of a millimeter.

Control system advancements have been particularly transformative in roll forming technology. Modern CNC systems manage not only the forming process itself but also integrated auxiliary operations such as pre-punching, notching, embossing, and cutting. This integration enables the production of finished components in a single continuous operation, eliminating secondary processing steps and reducing handling requirements. Sophisticated servo-driven cutting systems can synchronize with the forming process to produce precise lengths and complex end profiles, while vision systems and laser measurement technologies provide closed-loop feedback to maintain quality standards throughout production runs.

Selecting the Right Roll Forming Machine: Key Considerations

Technical Specifications and Performance Parameters

Selecting appropriate roll forming equipment requires careful consideration of multiple technical factors that align with specific production requirements. Material characteristics, including type, thickness, width, and mechanical properties, fundamentally influence machine selection. Different materials exhibit distinct forming behaviors, with variations in springback, work hardening, and surface sensitivity necessitating specific roll designs, drive capacities, and guide configurations. The complexity of the target profile significantly impacts station count, roll diameter, and drive power requirements, with more complex profiles demanding additional forming stations and potentially larger, more robust machinery.

Production volume and operational requirements also play crucial roles in the selection process. High-volume applications typically benefit from dedicated forming lines with integrated auxiliary operations, while lower-volume or high-variety production scenarios favor more flexible systems with quick-change tooling and simplified setups. Additional considerations include available floor space, utility requirements, and compatibility with existing material handling systems. A comprehensive assessment of these factors ensures the selection of equipment that not only meets current production needs but also accommodates anticipated future requirements.

Supplier Evaluation and Quality Assessment

Beyond technical specifications, the selection of a roll forming equipment supplier demands careful evaluation of multiple factors that influence long-term performance and reliability. A manufacturer’s technical expertise, demonstrated through engineering capability, industry experience, and application knowledge, provides critical insight into their ability to deliver effective solutions. Production facilities equipped with modern manufacturing equipment, quality control systems, and testing capabilities typically deliver superior equipment with better long-term reliability and performance.

Comprehensive service and support offerings represent another crucial consideration when selecting a roll forming equipment supplier. Technical support responsiveness, spare parts availability, training programs, and preventive maintenance services significantly impact equipment uptime and productivity throughout the machine’s operational life. The growing emphasis on digital services, including remote diagnostics and predictive maintenance capabilities, further enhances support effectiveness while potentially reducing service costs and minimizing production interruptions.

Industry certifications, including ISO standards and CE marking, provide independent verification of a manufacturer’s commitment to quality and safety. Similarly, customer references and application case studies offer valuable insights into real-world performance and reliability. These factors collectively contribute to a comprehensive supplier assessment that supports informed decision-making and successful equipment acquisition.

The Future of Roll Forming Technology

Emerging Trends and Innovation Directions

The future of roll forming technology is being shaped by several convergent trends, with sustainability considerations increasingly influencing equipment design and operation. Energy-efficient drive systems, regenerative technologies, and optimized operational sequences reduce power consumption, while noise reduction features and closed-loop cooling systems minimize environmental impact. The industry’s growing emphasis on circular economy principles encourages designs that facilitate material efficiency, component reuse, and end-of-life recycling, aligning roll forming technology with broader sustainability objectives.

Advanced materials represent another significant frontier in roll forming technology development. The expanding use of advanced high-strength steels, aluminum alloys, and composite materials demands new forming strategies, tooling designs, and process controls. Research into material behavior during forming, including springback characteristics and work hardening effects, enables more accurate process modeling and improved first-time success in profile development. These advancements, combined with innovations in tooling materials and surface treatments, continue to expand the boundaries of what can be achieved through roll forming.

Zhongtuo Machine’s Vision for Advanced Roll Forming Solutions

As an industry leader with nearly two decades of experience, Zhongtuo Machine embodies the technological evolution occurring within the roll forming sector. The company’s development trajectory reflects the industry’s broader movement toward increasingly sophisticated, connected, and efficient manufacturing solutions. Zhongtuo’s integration of Siemens Cloud platforms, AI-driven diagnostics, and remote monitoring capabilities represents the vanguard of roll forming technology, offering customers unprecedented levels of operational visibility, maintenance efficiency, and production optimization.

Looking forward, Zhongtuo’s research and development initiatives focus on enhancing machine intelligence, expanding material capabilities, and reducing environmental impact. Developments in digital twin technology enable virtual commissioning and process optimization before physical implementation, while advanced simulation tools facilitate more accurate prediction of forming behavior and springback compensation. These innovations, combined with the company’s commitment to customer-driven development, position Zhongtuo to continue delivering innovative solutions that address evolving manufacturing challenges across diverse industries and applications.

Conclusion

Roll forming technology has established itself as a cornerstone of modern industrial manufacturing, offering unparalleled capabilities for producing continuous metal profiles with consistency, efficiency, and precision. The technology’s evolution from basic mechanical forming to sophisticated, digitally-enabled manufacturing systems reflects broader trends in industrial automation, connectivity, and intelligence. As market demands continue to evolve toward greater customization, faster response times, and enhanced sustainability, roll forming technology is poised to maintain its critical role in manufacturing ecosystems across diverse sectors.

For organizations considering roll forming technology, a systematic approach to equipment selection—encompassing technical requirements, supplier capabilities, and long-term operational objectives—provides the foundation for successful implementation. By aligning equipment features with specific application needs and production goals, manufacturers can leverage roll forming technology to enhance competitiveness, expand capabilities, and drive operational excellence. As demonstrated by industry leaders like Zhongtuo Machine, the ongoing innovation in roll forming technology continues to create new possibilities for manufacturers worldwide, transforming raw materials into precisely engineered components that shape our built environment and enable technological progress across countless industries.