Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

ZHOHGTUO New Material Corrugated Roofing Sheet Roll Forming Machine

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

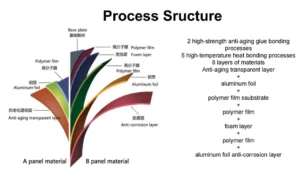

ZHONGTUO new materials have the following functions and are ideal materials to replace ordinary metal roof tiles

Acid and alkali resistance, corrosion resistance

Aging resistance, 30 year color fastness

Thermal insulation, environmental protection and energy conservation

Convenient installation and labor saving

The service life is 2-3 times of that of ordinary metal roof tiles, and the price is about 130% of that of ordinary color steel tiles

ZHOHGTUO corrugated roofing sheet roll forming machine, patented design Both ordinary PPGI GI PPGL GL roofing materials and new multifunctional roofing materials designed and produced by ZHONGTUO can be used.

Feature and technical parameter of corrugated roofing sheet roll forming machine.

Both common metal roofing materials and new multi-function roofing materials can be used, the machine of other suppliers can only use ordinary metal roofing materials.

Easy to install, easy to operate,

Longer service life, low failure rate

On year warranty, lifelong technical support.

Roller Shaft: 70mm, solid 45# steel, quenched treatment

Rollers: 45# steel, Chromed treatment, improve the hardness and prevent abrasion, anti corrosion increase of service life

Rolling station: 18 stations

Production speed: 0-15m/min

PLC control system: Delta, touch screen

Inverter: Delta

Cutting blade: Cr12MoV, heat treatment

Low voltage electric parts: Schneider brand

Encode: Omron

Double pillar structure hydraulic cutting system

Hydraulic station with cooling system, in case the oil temperature getting hot when the machine working for hours continuously, ensure the hydraulic oil in a constant temperature to have enough power for cutting device

All the tubes and wires will be marked by the numbers or letters,so that it will be very easy to connect for the new.

More pictures of corrugated roofing sheet roll forming machines

Corrugated Roof Sheet Machine video channel

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.