Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

US CZU SECTION STEEL MACHINE

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

US C/Z/U SECTION STEEL MACHINE

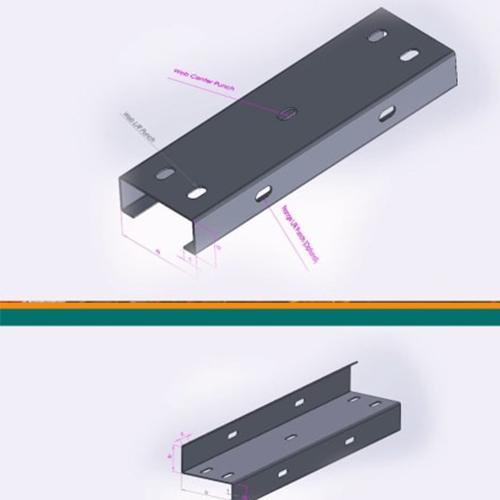

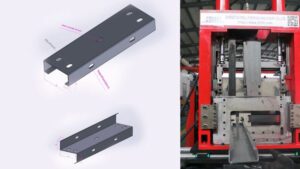

Fully automatic C/Z/U integrated machine equipment, with multiple types of C, Z, and U, producing multiple shapes and sizes with one machine。

The production process of the fully automatic CZ steel integrated machine is fully automated, and there is no need to replace the forming rollers when changing specifications, saving users a lot of investment costs and site space.

CZ steel equipment is a type of equipment used for steel processing, mainly for cutting, forming, punching and other processing of steel. The main advantages of CZ steel equipment are simple operation, high efficiency, high precision, and long service life.

The launch of CZ type steel integrated machine is a transformation of the steel structure industry’s innovation and cost saving project. The main features of the equipment are as follows:

- Cutting does not require changing the blade head;

- Quick changeover, any changeover within three minutes;

- Adjustable, the web, flange, and edge can all be adjusted in millimeters;

- CZ steel integrated machine, CZ three-step transformation;

- Coaxial design reduces the problem of uneven height on both sides caused by broken shafts.

Purlin machine video channel

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.