Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

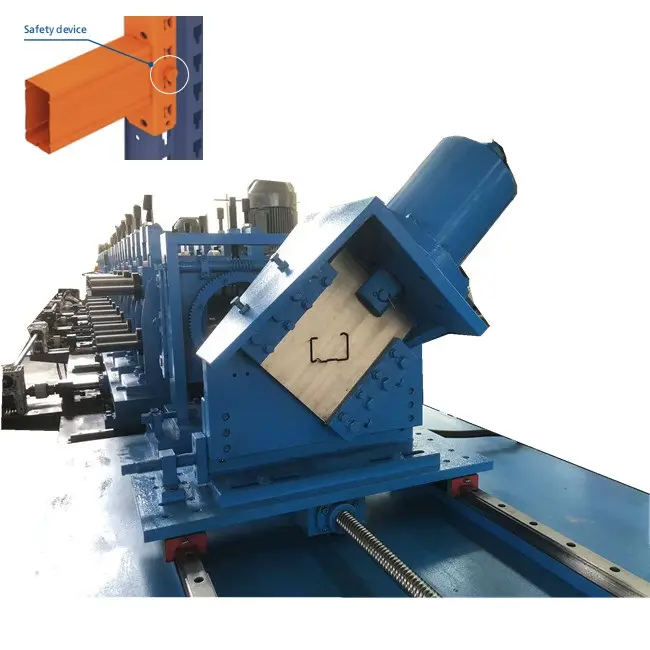

Upright Rack Roll Forming Machine: The Core Power for High-Quality Storage Rack Production

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

In the era of intelligent logistics and efficient warehousing, storage racks are the “skeleton” of warehouse operations, and the upright rack—bearing the entire load of the rack system—is the key to ensuring storage safety and stability. Our Upright Rack Roll Forming Machine is tailor-made for high-standard upright rack production, integrating precision forming, efficient operation and stable performance. It helps you create high-strength, consistent and cost-effective upright racks, and becomes a solid support for your business development in the warehousing equipment market.

Focus on Core Demands: Precise Forming Ensures Load-Bearing Safety

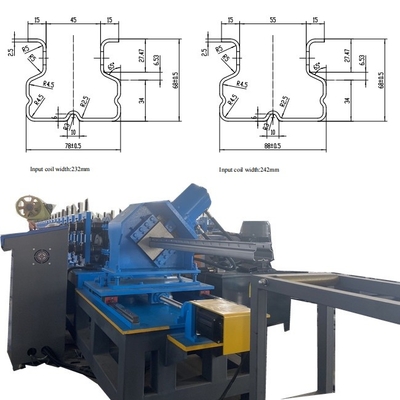

Equipped with high-precision machined roll sets, the machine adopts multi-pass progressive forming technology to accurately shape the upright rack profiles (such as C-shaped, U-shaped, and special customized profiles). Each roll is made of high-quality alloy steel and undergoes quenching and tempering treatment, with a surface roughness of less than Ra0.8μm, ensuring that the formed upright rack has uniform wall thickness, clear edges and corners, and no burrs or deformation. The built-in high-precision encoder and PLC control system realize real-time monitoring and automatic adjustment of the forming process, with a dimensional tolerance control within ±0.1mm, which effectively avoids the problem of poor load-bearing performance caused by irregular profiles.

High-Speed Operation to Break Through Production Bottlenecks

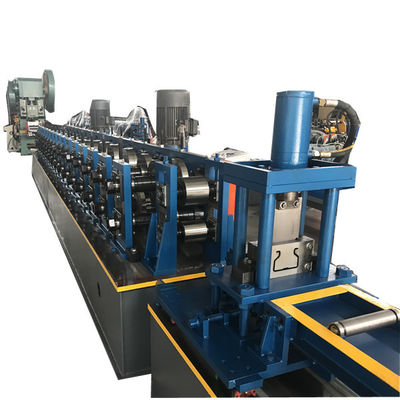

Adopting a high-power servo drive system and an optimized transmission structure, the machine’s production speed can reach 12-20 meters per minute, which is 30% higher than that of traditional equipment. The automatic feeding, forming, punching, cutting and discharging integrated line realizes unmanned operation in the whole process, which not only reduces labor costs, but also avoids production delays caused by manual operation errors.

Stable and Durable to Reduce Long-Term Operating Costs

The machine frame is made of 20mm thick high-quality steel plate, which is welded by people and undergoes stress relief treatment, with strong anti-vibration performance and no deformation after long-term use. Key components such as bearings, reducers and motors are all imported from well-known brands, and the automatic lubrication system reduces the wear of moving parts, extending the service life of the machine to more than 12 years.

Humanized Design: Easy Operation and Intimate Guarantee

The machine adopts a user-friendly design concept, and the operation threshold is low. The 10-inch touch screen integrates parameter setting, process monitoring, fault alarm and other functions. The graphic interface is clear and easy to understand, and new employees can get started after 1 hour of training. The modular structure design makes key components easy to disassemble and maintain.

Choosing our Upright Rack Roll Forming Machine is to choose a reliable production partner. Whether you are a large-scale rack manufacturer or a new entrant in the industry, this machine can help you improve product quality, reduce production costs and expand market share. Contact us now to get a free technical solution and quotation, and start your efficient and high-quality production journey!

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.