Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

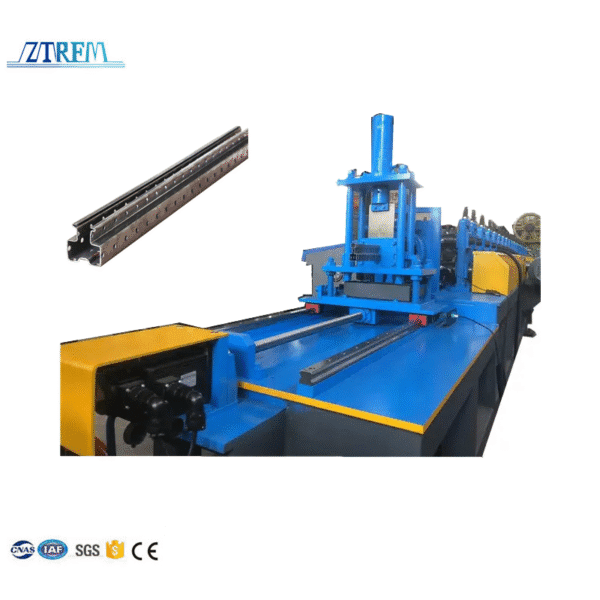

Upright Rack Roll Forming Machine:high efficiency production

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

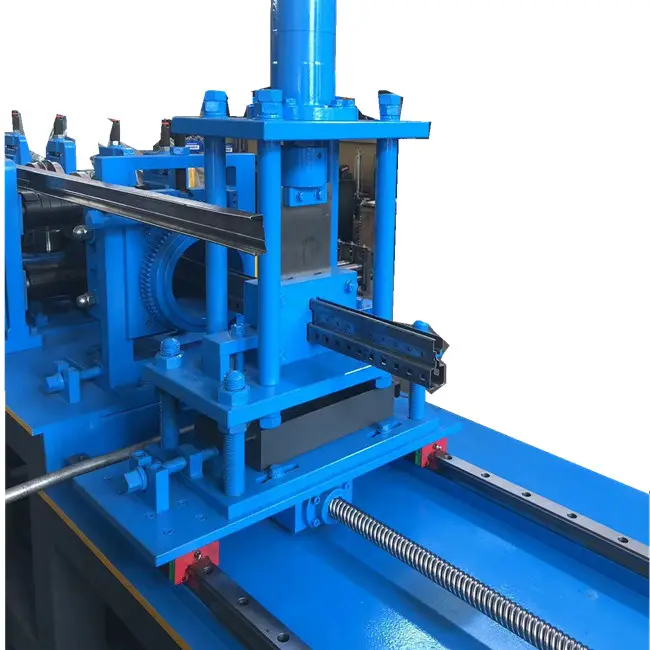

Our Upright Rack Roll Forming Machine features a unique design concept and advanced roller system. The meticulously engineered rollers boast an ultra-smooth surface that significantly reduces friction with metal sheets, ensuring smoother rolling and substantially improving production efficiency. A standout feature is the high-precision molds made from special materials with exceptional hardness and wear resistance, maintaining dimensional accuracy throughout extended production cycles. When manufacturing specific upright rack models, the molds achieve ±0.1mm precision control, guaranteeing consistent quality across all components. This eliminates defect rates caused by dimensional deviations, thereby enhancing both production efficiency and product quality.

Powerful performance, adaptable to diverse needs

This equipment delivers robust performance adaptable to diverse metal materials including carbon steel, stainless steel, and aluminum alloys. By precisely regulating parameters, our forming machine dynamically adjusts to material characteristics, ensuring optimal forming results across all materials. Whether manufacturing heavy-duty carbon steel shelves for warehouse storage, corrosion-resistant stainless steel racks, or lightweight aluminum alloy shelving systems, it excels in handling all requirements. Additionally, it produces vertical shelving systems in various specifications – from compact standard units to large industrial racks – meeting diverse market needs. For e-commerce warehousing applications, our equipment creates height-adjustable shelving solutions with customizable load capacities, providing efficient storage solutions tailored to different cargo storage requirements.

Stable quality, durable and robust

In our equipment manufacturing process, we employ advanced machining technologies and a rigorous quality control system. Every component undergoes meticulous processing and inspection to ensure compliance with high-quality standards. Critical components such as transmission systems and support structures utilize high-strength materials that not only exhibit excellent mechanical properties but also demonstrate superior fatigue resistance and corrosion resistance. Through optimized structural design, the equipment maintains exceptional stability during operation, minimizing vibration and noise. Even under prolonged, high-intensity working conditions, it operates reliably. This approach not only extends the equipment’s service life but also reduces maintenance costs.

Professional services, worry-free throughout

Choosing our vertical shelf rolling forming machine means not only acquiring high-quality equipment, but also enjoying comprehensive and attentive professional services.

Before-sales, we maintain a seasoned technical consulting team with solid expertise. With deep understanding of the metal processing industry’s needs and pain points, they provide customized solutions tailored to clients’ actual production scenarios. Whether addressing equipment parameter queries or discussing production processes, team members patiently answer questions, deliver detailed technical documentation, and offer recommendations to help clients make optimal choices. For instance, when a client plans to build a new shelf production line, our technicians collaborate with them to gather information on expected output, target markets, and raw material supply, then recommend the most suitable equipment models and configurations to ensure efficient operation after deployment.

We provide comprehensive installation and commissioning services during the sales process. Upon equipment delivery to the client’s facility, our professional installation team will promptly commence work, strictly adhering to established standards and procedures. Throughout this process, we conduct on-site training for the client’s operators, covering not only basic equipment operation techniques but also the equipment’s working principles and key maintenance points. This ensures operators gain full proficiency in operating the equipment, enabling safe and efficient production.

We provide prompt and reliable after-sales services. Our comprehensive after-sales network features professional technicians and a well-stocked spare parts inventory. When equipment malfunctions occur, our support team responds immediately via phone or remote assistance for troubleshooting. For minor issues, we offer self-service guidance; for complex cases, our technicians will arrive promptly to resolve the problem and restore equipment operation.

Start now to begin your efficient production journey

If you’re struggling with efficiency, cost, and quality issues in shelf production, our vertical roll forming machine for shelves is undoubtedly your ideal solution. Don’t hesitate—contact us now. Our expert team will promptly provide you with detailed product information and customized quotes.

Choosing our equipment means adopting a high-efficiency, premium-quality, and cost-effective production approach, giving your business a competitive edge in today’s market. Let’s collaborate to embark on a journey of efficient production, jointly create greater commercial value, and step into a new chapter of success.

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.