Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

The Role of Drip Edge and Roof Edge in Roofing Systems: A Comprehensive Guide

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

Drip edge and roof edge are two essential components in roofing systems that play a crucial role in protecting buildings from water damage. These components are typically made using roll forming machines, which are versatile and efficient tools used in the manufacturing industry.

Drip edge is a metal strip that is installed along the roof’s edge to direct water away from the fascia and soffit, preventing water damage and protecting the building’s structure. It is commonly made using roll forming machines, which bend and shape metal sheets into the desired shape. The roll forming machine uses a series of rollers to gradually form the metal into the desired shape, ensuring consistency and accuracy in the final product. Drip edge is particularly useful in areas with high rainfall, as it helps to channel water away from the building and prevent water buildup.

Roof edge, on the other hand, is a metal trim that is installed along the perimeter of the roof to provide a neat and finished appearance. It is also made using roll forming machines, which can create complex shapes and designs. The roll former can bend and shape the metal into intricate patterns, allowing for a customized look that complements the building’s architecture. Roof edge can be made from various materials, including aluminum, steel, and copper, and is often coated to resist corrosion and weathering.

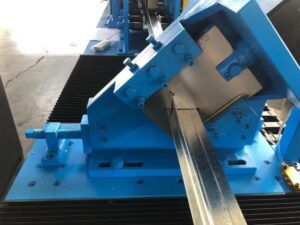

Roll forming machines are used to manufacture both drip edge and roof edge. These machines are designed to process metal sheets and transform them into the desired shape. They consist of a series of rollers that gradually bend the metal until it forms the desired shape. The process is automated and efficient, making it a popular choice for mass production. The roll forming machine can be programmed to create different shapes and sizes, depending on the specific requirements of the project.

To operate a roll forming machine, the metal sheet is first loaded onto the machine’s feeding system. The machine then guides the sheet through the rollers, gradually forming it into the desired shape. The operator can adjust the speed and pressure of the rollers to ensure a consistent and accurate output. The machine can also incorporate additional features, such as cutting and punching, to create customized products.

When using a roll forming machine to manufacture drip edge or roof edge, it is essential to follow safety guidelines and procedures. Operators should wear protective gear and ensure that the machine is properly maintained. They should also be trained in the proper use of the machine and be aware of any potential hazards.

In conclusion, drip edge and roof edge are crucial components in roofing systems that provide protection and aesthetic value. They are made using roll forming machines, which are efficient and versatile tools used in the manufacturing industry. With proper use and maintenance, roll forming machines can produce high-quality products that meet the specific needs of the project. By understanding the importance of these components and the process of their production, building owners and contractors can ensure the longevity and durability of their roofing systems.

Operating a Roll Forming Machine: A Guide for Users

Roll forming machines are powerful tools used in the manufacturing industry to produce a variety of metal products, including drip edge and roof edge. To ensure safe and efficient operation, it is essential to follow the steps outlined below:

Preparation: Before starting the machine, ensure that the metal sheet is properly aligned and loaded onto the feeding system. Check the machine’s settings and make any necessary adjustments to ensure that it is ready for use. This includes checking the rollers, cutting tools, and any additional features.

Safety: Wear protective gear, such as gloves and safety glasses, to protect yourself from potential hazards. Ensure that the machine is properly maintained and that all safety features are in place.

Starting the Machine: Turn on the machine and allow it to warm up. Set the desired speed and pressure for the rollers, depending on the thickness and material of the metal sheet.

Feeding the Sheet: Guide the metal sheet through the rollers, ensuring that it is properly aligned and that the rollers are engaged. Gradually increase the speed as the sheet passes through the machine.

Monitoring: Keep a close eye on the machine’s operation, making any necessary adjustments to the rollers or settings as needed. Ensure that the sheet is being formed into the desired shape and that there are no defects or issues.

Cutting and Finishing: Once the sheet has been formed, use the cutting tool to trim it to the desired length. Apply any necessary coatings or finishes to the product to protect it from corrosion and weathering.

Maintenance: Regularly clean and maintain the machine to ensure its longevity and reliability. This includes checking the rollers and other components for wear and tear.

By following these steps, users can produce high-quality drip edge and roof edge products that meet the specific needs of their projects. It is important to follow safety guidelines and procedures and to be trained in the proper use of the machine to avoid accidents or injuries. With proper use and maintenance, roll forming machines can provide a reliable and efficient solution for manufacturing metal products.

In summary, operating a roll forming machine requires attention to detail and adherence to safety guidelines. By following these steps and maintaining the machine, users can produce high-quality products that meet the needs of their projects. Whether you are producing drip edge or roof edge, a roll forming machine is a valuable tool that can streamline the manufacturing process and ensure consistent and accurate output.

The machine frame adopts a 20mm thick steel plate welding structure. Ensure that the machine can bear larger weight rollers and roller frames.

The material of the roller is GCr12 MOV

Roller diameter: 60mm

The material of the roller is 40Cr

The roller shaft frame is: mold frame

Machine running speed: 45m per minute

Cutting blade material: GCr12

Cutting method: servo tracking cutting

Servo motor power: 2.3kw

Drive motor power: 7.5+7.5kw

Cut off power: 5.5kw

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.