Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

Supermarket Storage Rack Roll Forming Machine:Empowering the efficient upgrade of supermarket and warehouse storage systems

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

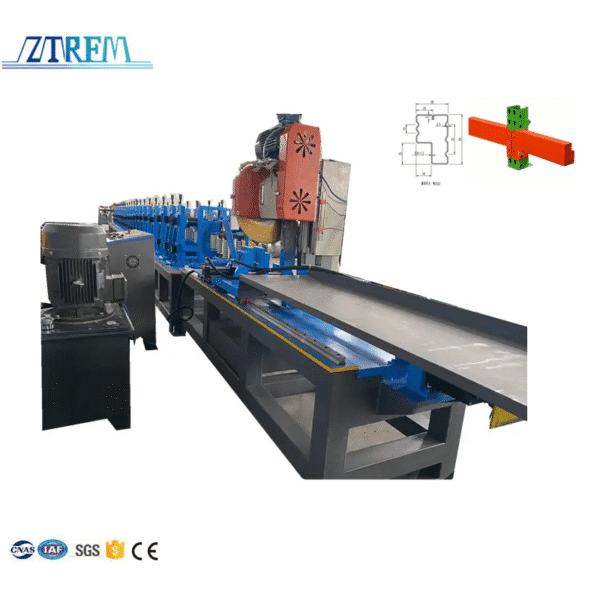

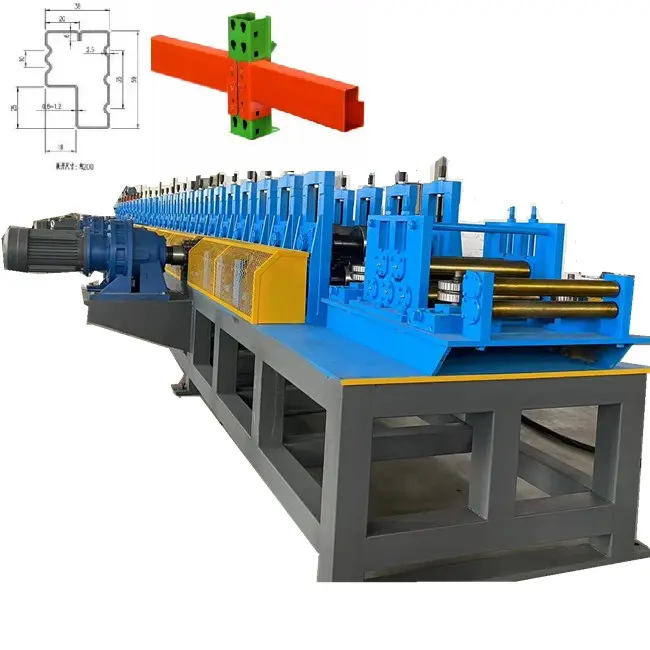

In response to the production characteristics of supermarket shelves, our Supermarket Storage Rack Roll Forming Machine has been comprehensively customized, from core components to control systems, precisely meeting the needs of commercial and supermarket scenarios. A major advantage of the equipment is its modular roller assembly, made of imported German alloy steel, which undergoes carburizing and quenching treatment, achieving a surface hardness of over HRC60. This not only easily handles common materials for supermarket shelves such as 1.2-3.0mm thick cold-rolled steel plates and galvanized steel plates but also supports rapid replacement. For the three common types of supermarket shelves—light, medium, and heavy—the roller assembly can be switched within 30 minutes, significantly improving the production efficiency of multiple small batches.

The high-precision forming system has completely resolved the accuracy challenges of traditional equipment. Equipped with Panasonic servo motors and Siemens PLC control systems, the system achieves full automation with precision control, maintaining forming accuracy within ±0.3mm and shelf board flatness error below 0.5mm, fully compliant with the GB/T 27924-2011 standard for supermarket shelves. Additionally, the system integrates online punching and cutting functions, eliminating the need for secondary processing. From raw material input to finished shelf columns and board forming, the entire process is completed with a single button press, reducing production time by 60%. A single unit can produce up to 120 sets daily, quadrupling the output of traditional equipment.

Secure and stable performance, adaptable to complex scenarios

The operational safety of supermarket shelves directly impacts both personnel and product integrity. To address this, our equipment incorporates multiple safety safeguards during production. Equipped with infrared safety sensors, the system automatically halts operation within 0.1 seconds when an operator approaches the active forming zone, preventing accidents at the source. Throughout the forming process, a real-time dimensional inspection system performs precision checks on each product. If any dimensional deviations are detected, the equipment triggers an automatic alarm and shutdown, ensuring non-compliant products are rejected before proceeding to subsequent processes.

To address rust-prone issues in supermarket fresh food and cold chain storage shelves, this equipment is compatible with specialized materials like galvanized steel plates and color-coated steel sheets. Through precise temperature control and roller pressure adjustment, it maintains coating integrity while enhancing rust resistance and corrosion resistance, thereby extending shelf lifespan. Whether for standard shelves in ambient storage areas or specialized shelves in low-temperature cold chain zones, the equipment ensures stable production to meet diverse warehouse requirements.

Full-chain foreign trade services, ensuring seamless cooperation throughout the process

As a professional foreign trade equipment supplier, we fully understand the complexities of cross-border collaboration. That’s why we provide global clients with a one-stop, end-to-end service, ensuring hassle-free and worry-free cooperation throughout the entire process.

During the pre-sales phase, our multilingual technical team (supporting 8 languages including English, Spanish, and Arabic) will conduct in-depth analysis of the client’s production scale, target markets, and product requirements. By aligning with local supermarket industry standards and material characteristics, we provide customized equipment configuration plans and production process recommendations, along with detailed equipment specifications, quotations, and an industry solutions white paper.

During the sales phase, we handle all export procedures for the equipment, including customs clearance, inspection, and shipping bookings, to ensure safe and timely delivery to the client’s facility. Upon arrival, our professional engineers will provide on-site installation and commissioning services, offering comprehensive guidance on equipment operation, mold replacement, and daily maintenance until full operational proficiency is achieved. Additionally, we provide international certifications such as CE and ISO to ensure compliance with target market regulations.

During the post-sale phase, we have established a 24/7 global service hotline and an online technical support platform. The core components of the equipment come with an 18-month warranty, during which damaged parts are replaced free of charge. After the warranty period, we provide discounted spare parts to ensure long-term stable operation. Additionally, we conduct regular follow-up visits to monitor equipment usage, offer technical upgrade suggestions, and help customers continuously improve production efficiency.

Global customers witness, strength builds reputation

Our Supermarket Storage Rack Roll Forming Machine has been exported to over 30 countries and regions, serving more than 200 supermarket shelf manufacturers and earning customer recognition through proven performance. PT Sinar Jaya, a renowned Southeast Asian supermarket equipment supplier, had long struggled with the inefficiency and high costs of traditional equipment, making it difficult to handle bulk orders from large chain supermarkets. After adopting our equipment in 2023, their production efficiency tripled, reducing the product defect rate from 12% to 0.8%. This breakthrough enabled them to secure the annual shelf supply contract for Indomaret, Indonesia’s largest supermarket chain, with annual sales soaring by 120%.

European company ITALIA RACKS faced production challenges in cold chain shelving. Traditional equipment often caused coating damage during galvanized steel processing, leading to rapid rusting in cold storage environments. By adopting our precision rolling control technology, we achieved a 99.5% coating integrity rate. This innovation extended the shelf lifespan from 2 years to over 5 years, strengthening our partnership with local supermarket chain Coop while successfully expanding into new markets like France and Spain.

A leading Chinese shelf manufacturer supplying Walmart and Yonghui supermarkets with shelf solutions, implemented our three automated systems to establish a production line. This upgrade boosted daily output from 80 to 350 units, cut delivery time from 7 to 2 days, and achieved 100% order fulfillment rate (up from 75%). Customer satisfaction soared, with annual orders growing by 80%.

Seize the opportunity in supermarket and warehouse storage, start cooperation now

The global supermarket retail sector is experiencing rapid expansion. According to Statista, the worldwide supermarket warehouse equipment market is projected to exceed $30 billion by 2025, with shelves remaining a core component that maintains strong market demand. By choosing our Supermarket Storage Rack Roll Forming Machine, you’re not just adopting an efficient, precise, and cost-effective production solution – you’re riding the wave of innovation in the supermarket warehousing industry.

Whether you need to boost your current production capacity, expand into new supermarket clients, or tackle the pain points of traditional manufacturing, we offer tailored solutions. Contact us now to receive a free equipment demo video, a personalized quote, and the chance to get one-on-one online consultation from our technical engineers.

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.