Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

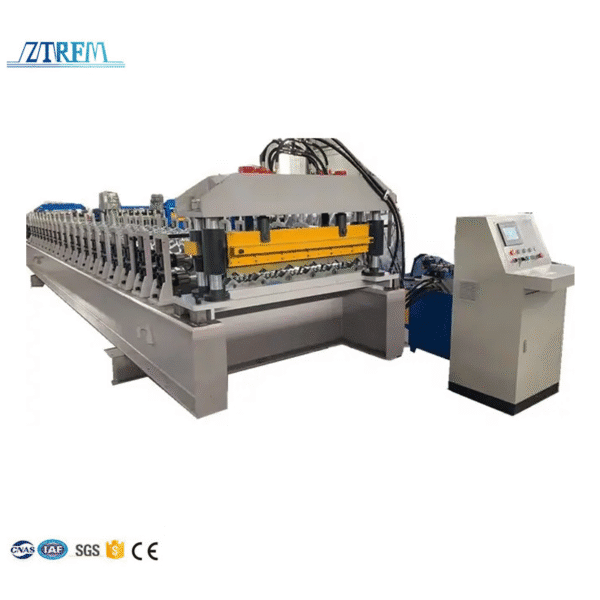

Step Tile Profile Rolling Forming Machine: Opening a New Era of Efficient Production

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

Our step tile profile rolling forming machine is engineered with advanced design and state – of – the – art technology to ensure high – speed production. It features a continuous rolling process that minimizes idle time between operations. The optimized roller design allows for smooth and rapid transformation of metal sheets into step tiles. With a high – speed motor and efficient transmission system, it can process a large number of metal sheets per hour, significantly increasing your production output. This not only enables you to meet tight deadlines but also gives you a competitive edge in the market by being able to supply more products in less time.

Precision molding, quality assurance

Precision is at the heart of our machine’s design. The rolling process is computer – controlled, ensuring that each step tile is formed with utmost accuracy. The tolerance of the formed tiles is extremely low, which means that the products have a consistent shape and size. This high – level precision not only meets but often exceeds industry standards. Whether it’s the height, width, or angle of the step tile, our machine can achieve precise forming, reducing the number of defective products. High – quality step tiles are crucial for the stability and aesthetics of any construction project, and our machine guarantees that you get the best – quality products every time.

Robust and durable, cost-effective

Built with a heavy – duty steel frame and high – quality components, our step tile profile rolling forming machine is designed to last. The rollers are made from wear – resistant materials that can withstand the continuous pressure and friction during the rolling process. This durability means that the machine requires less frequent maintenance and replacement of parts, significantly reducing your operational costs in the long run. You don’t have to worry about unexpected breakdowns that can disrupt your production schedule and lead to costly downtime. Moreover, the long – lasting nature of the machine provides a better return on investment, making it a cost – effective choice for your business.

Widely applicable and meets diverse needs

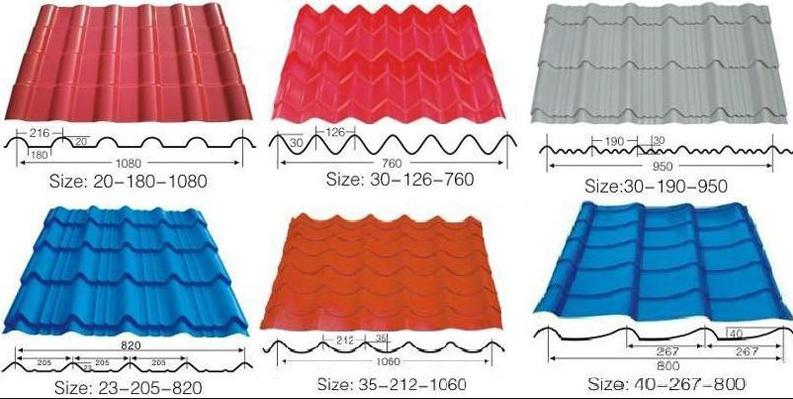

Our step tile profile rolling forming machine has a wide range of applications across various industries.

In the construction industry, step tiles produced by our machine are the first choice for roofing projects. Their unique shape provides excellent water – proofing and weather – resistance properties. Whether it’s a residential building, a commercial complex, or an industrial shed, these step tiles can enhance the durability and aesthetics of the roof. For example, in many modern residential areas, the step – tiled roofs not only protect the houses from rain and snow but also add a touch of elegance to the overall appearance. In large – scale industrial buildings, the high – strength step tiles can withstand heavy wind loads and long – term exposure to the elements, ensuring the safety and stability of the building structure.

In the industrial field, our step tile products are used in the construction of factory floors and platforms. The anti – slip surface of the step tiles provides a safe working environment for workers, reducing the risk of accidents. In factories where heavy – duty machinery is in operation, such as steel mills and automotive manufacturing plants, the strong and durable step tiles can withstand the pressure and friction from the movement of heavy equipment.

Furthermore, the machine’s products also find applications in infrastructure projects. For instance, in the construction of bridges and overpasses, step tiles can be used to create walkways and drainage systems. Their corrosion – resistant properties make them suitable for long – term use in outdoor and humid environments.

Technical specifications, professional support capabilities

Here are the key technical parameters of our Step Tile Profile Rolling Forming Machine, which reflect its high – end performance and professional – grade quality:

Power: Equipped with a 11 kW high – efficiency motor. This powerful motor ensures stable operation during high – speed production, providing sufficient driving force for the continuous rolling process. Whether it’s processing thin – gauge or thick – gauge metal sheets, the motor can maintain consistent performance, reducing the risk of power – related production interruptions.

Processing Plate Thickness Range: It can handle metal sheets with a thickness ranging from 0.3 mm to 0.7mm. This wide thickness range makes the machine suitable for various applications. For light – duty roofing projects in residential areas, it can process thin – walled metal sheets with precision. When it comes to heavy – duty industrial construction, such as large – scale factory buildings, it can also handle thick – gauge metal sheets to meet the requirements of high – strength structures.

Rolling Speed: The machine has a maximum rolling speed of 30m/min. This high – speed rolling not only improves production efficiency but also ensures the uniformity of the formed step tiles. Faster rolling speed means that more products can be produced within the same time frame, which is beneficial for large – scale production orders.

Forming Accuracy: The forming tolerance is controlled within ±1mm. This high – level accuracy ensures that each step tile produced has a consistent shape and size, meeting the strictest quality standards in the industry. Whether it’s the height, width, or angle of the step tile, the precise forming ensures that the tiles fit together perfectly during installation, enhancing the overall quality and aesthetics of the construction project.

Overall Dimensions: The machine’s overall dimensions are 8.5×1.8×1.6 mm. These dimensions are designed to optimize the machine’s space – utilization in the production workshop while also ensuring easy transportation and installation. The compact yet sturdy design makes it suitable for both small – scale and large – scale production facilities.

Customized services tailored to your needs

We understand that every customer may have unique production requirements. That’s why we offer comprehensive customization services for our Step Tile Profile Rolling Forming Machine. Whether you need to adjust the machine to process special – sized metal sheets, or you have specific requirements for the shape and structure of the step tiles, our professional R & D team is ready to assist.

For example, if you are working on a special architectural project that requires step tiles with non – standard angles or dimensions, our team can customize the machine’s roller design and control system accordingly. We will work closely with you from the initial design concept to the final production, ensuring that the customized machine meets your exact needs. Additionally, we can also provide customized after – sales service packages to ensure the smooth operation of the machine throughout its service life. With our customization services, you can rest assured that our step tile profile rolling forming machine will be the perfect fit for your unique business needs.

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.