Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

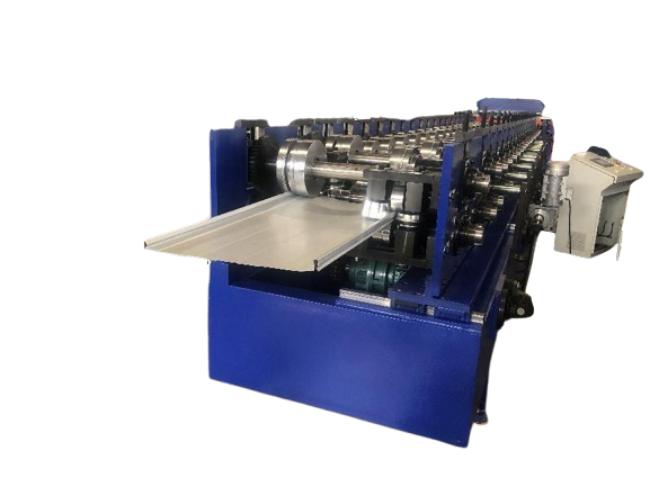

Standing Seam Roll Forming Machine: Precision & Efficiency Redefined

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

As a leading supplier of metal forming equipment, we take pride in presenting our Standing Seam Roll Forming Machine—a game-changer for your roofing and cladding projects. Engineered with global standards in mind, this machine combines robust performance, exceptional precision, and user-friendly operation to elevate your production line and boost market competitiveness.

Unmatched Advantages for Your Production

Our standing seam roll forming machine is designed to address the core demands of metal processing industries, with advantages that stand out in the global market:

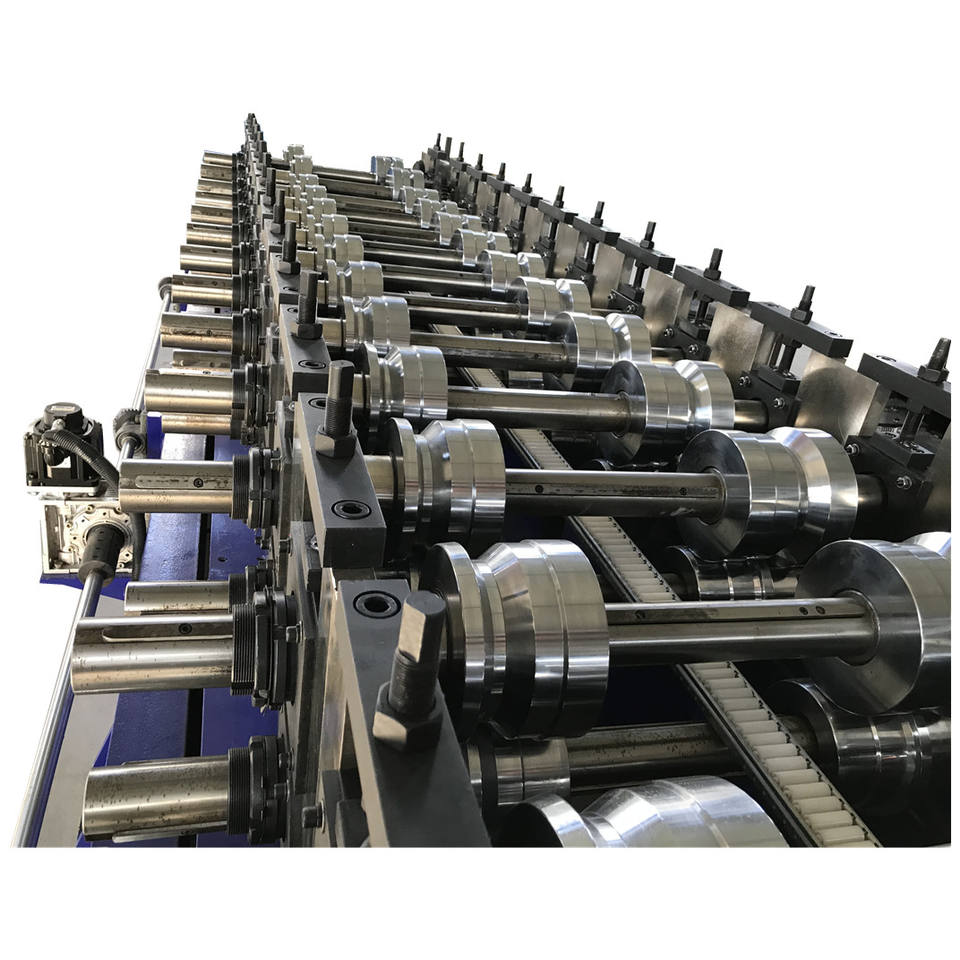

1.Superior Forming Precision, Consistent Quality

Equipped with high-hardness alloy rollers (HRC 58-62) and a precision-guided transmission system, the machine ensures uniform seam height, tight locking, and smooth surface finish for every metal sheet. The error margin of seam dimensions is controlled within ±0.1mm, perfectly meeting the strict standards of architectural and industrial roofing applications. No more rework—just reliable, consistent products batch after batch.

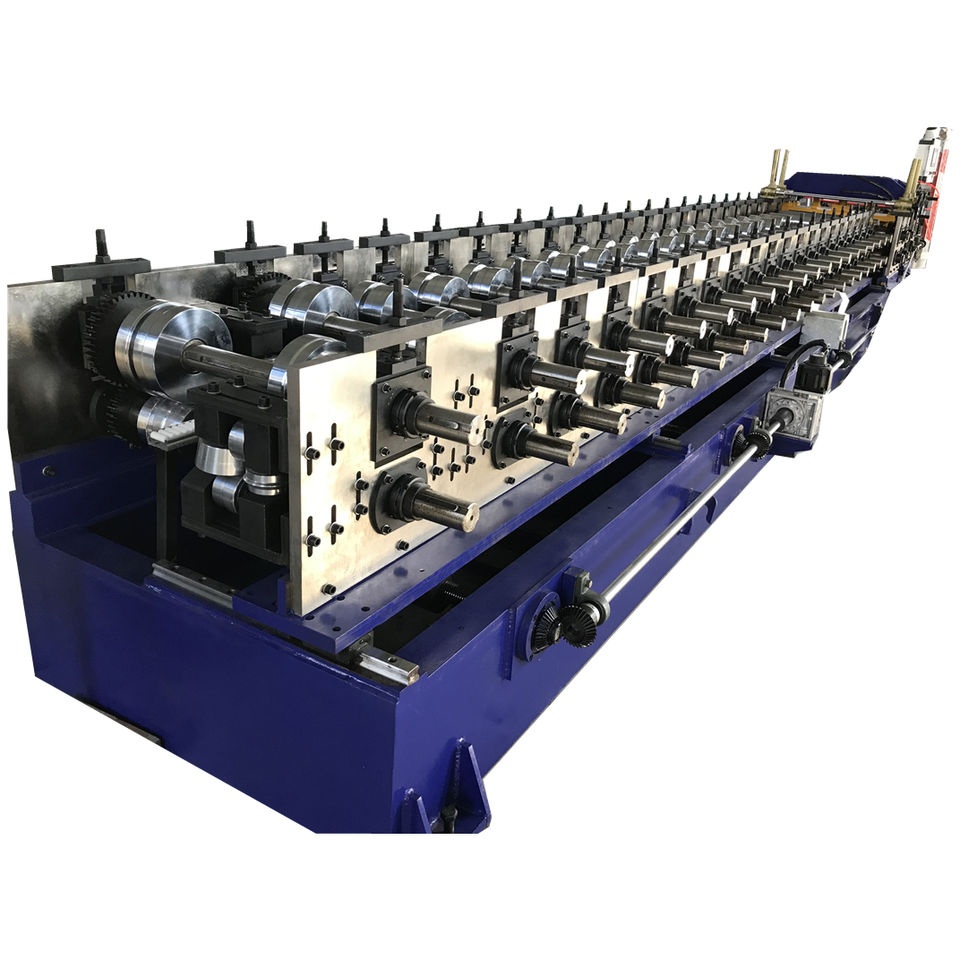

2.High-Speed Production, Maximized Output

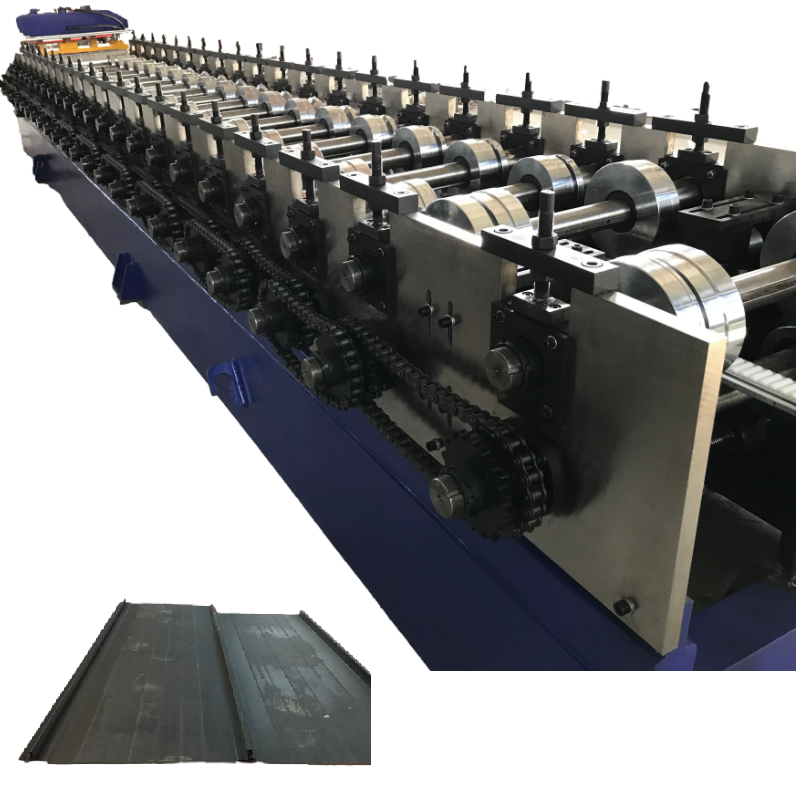

With a maximum forming speed of 15-20m/min (adjustable according to material thickness), the machine significantly outperforms traditional equipment. It supports continuous feeding and automatic cutting, minimizing downtime between processes. Whether processing aluminum, galvanized steel, or color-coated steel (0.3-1.2mm thickness), it maintains stable performance, helping you fulfill large orders efficiently and meet tight delivery deadlines.

3.Flexible Customization, Wide Application

We understand that different markets have diverse requirements. Our machine offers flexible adjustment of seam types (such as snap-lock, mechanical lock) and sheet widths (300-600mm customizable). It is ideal for manufacturing standing seam roofing panels, wall cladding, and decorative metal sheets used in commercial buildings, industrial warehouses, villas, and agricultural facilities—adapting to your specific project needs with ease.

4.Durable Structure, Low Maintenance Cost

The main frame is made of heavy-duty steel with integral welding and tempering treatment, ensuring strong load-bearing capacity and resistance to deformation. Key components are sourced from international brands, reducing failure rates. The machine features a modular design, making routine maintenance and part replacement simple—lowering your long-term operation costs.

5.Intelligent Operation, Easy to Master

Equipped with a touch-screen control system, the machine allows one-click setting of parameters (length, quantity, speed) and real-time monitoring of production status. It has built-in fault alarm functions (such as material shortage, overload) to avoid production accidents. Even new operators can master the operation within a short training period, reducing labor costs.

standing seam machine video channel

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.