Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

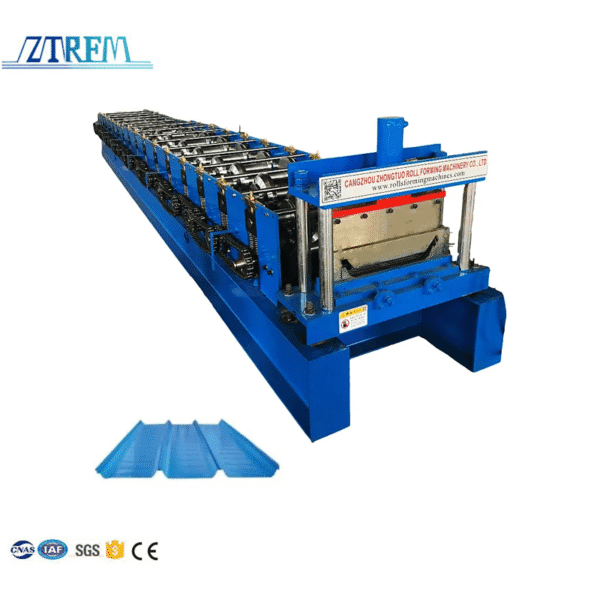

Standing Seam Roll Forming Machine: Defining a New Paradigm for High-end Roof Production

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

As buildings evolve beyond basic shelter functions, roofing systems have become a key metric for evaluating architectural quality, energy efficiency, and aesthetic value. In Europe, the low-carbon building movement is driving the integration of waterproofing and photovoltaic systems into roofing solutions. In North America, frequent extreme weather events are pushing roofing materials to withstand stronger wind and seismic forces. In Southeast Asia, the high-temperature and high-humidity climate imposes stringent requirements on roofing corrosion resistance and heat dissipation. The vertical seam roof system, with its seamless assembly, structural stability, and long service life, offers inherent advantages in these challenging environments.

The Structural Upgrade from “Fit” to “Fusion”

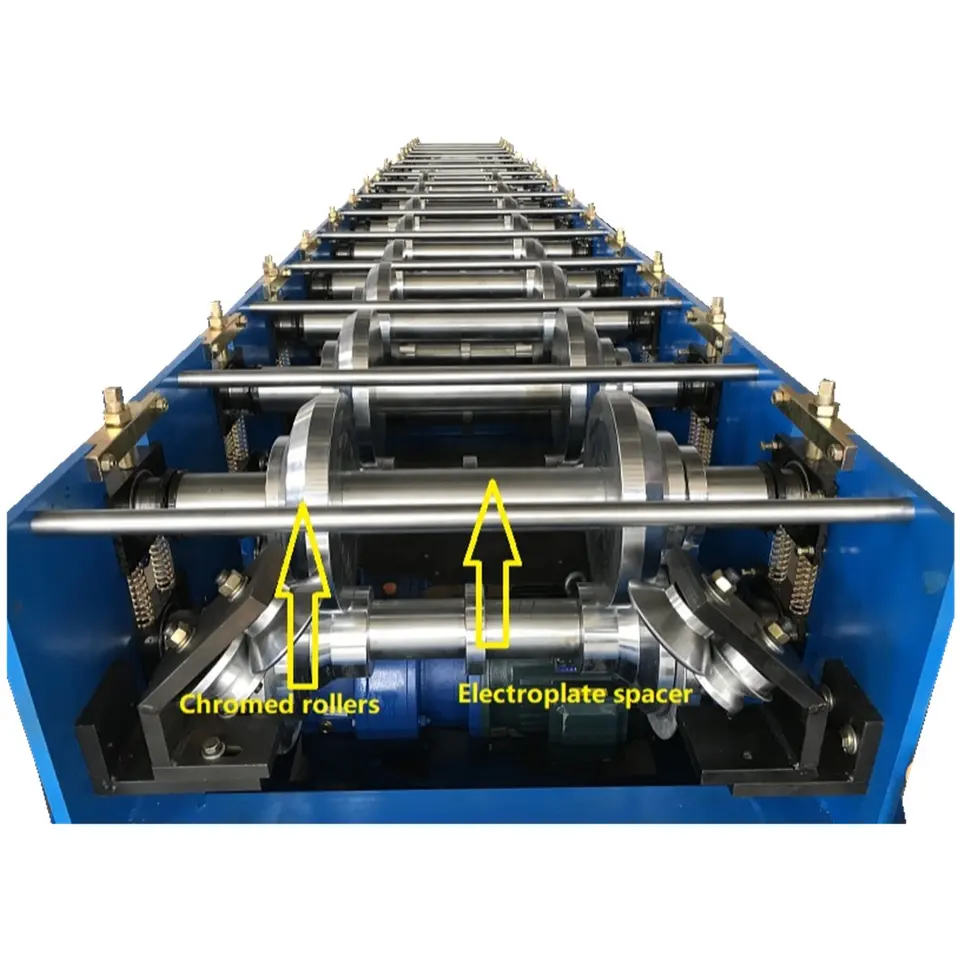

Waterproofing is the lifeblood of roofing, with edge locking being its core. Our forming machine has revolutionized traditional single-roll pressing by adopting an innovative ’20-stage progressive forming + 3-stage edge locking reinforcement’ process. Through CNC system precision control of pressure and angle for each roller set, the roof tile edge locking achieves dual protection through ‘mechanical interlocking + structural interlocking’.

In a Nordic ski resort project, the titanium-zinc composite roof tiles manufactured by this equipment not only withstand extreme cold (-30°C) and heavy snowfall, but their tightly sealed edges also prevent water leakage from melting snow, ensuring safe operation of indoor facilities.

One device handles all materials and all styles.

To meet the diverse needs of raw materials and patterns in the global market, our equipment has achieved dual breakthroughs in “full material compatibility + rapid pattern switching.” In terms of material adaptation, it can easily process various metal sheets such as 0.6-2.0mm thick galvanized steel, aluminum-manganese-manganese alloy, titanium-zinc plates, and copper without replacing core components. For pattern adjustment, parameters like edge locking height, sheet length, and corrugation shape can be set up through a touchscreen, complemented by a quick-change mold design.

Adapting to diverse global building needs

From the frigid Nordic regions to the scorching African deserts, from the humid Southeast Asia to the arid Middle East, our Standing Seam Roll Forming Machine produces roofing tiles that have successfully adapted to extreme environments and diverse construction scenarios worldwide.

In public architecture, this technology has become the go-to solution for landmark projects. A European football stadium’s roof tiles, manufactured with our equipment, not only meet the structural demands of large-span roofs but also feature photovoltaic modules on their smooth surfaces, achieving the low-carbon goal of “roof power generation.” At a Middle Eastern international airport, corrosion-resistant titanium-zinc sheets processed by our equipment effectively withstand local salt-alkali sand erosion, with an expected service life of 50 years.

This technology also demonstrates exceptional performance in residential and industrial applications. A premium villa community in North America utilizes color-coated vertical seam tiles manufactured with this system, combining aesthetic appeal with practical functionality. The tightly sealed seam structure ensures structural integrity even during hurricane seasons. In Southeast Asia, a food processing plant’s roof employs corrosion-resistant aluminum, magnesium, and manganese tiles, effectively preventing rust in high-temperature and high-humidity environments while maintaining hygienic safety standards for production facilities.

standing seam machine video channel

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.