Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

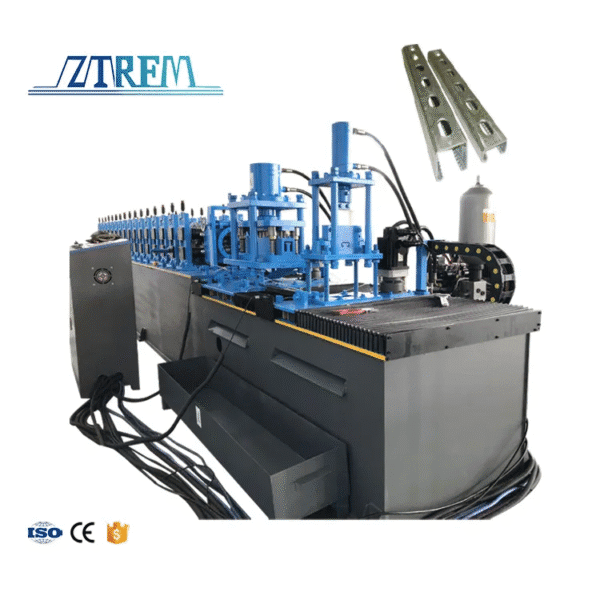

Solar Strut Channel Roll Forming Machine: The Backbone of Efficient Solar Installations

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

As the global shift toward renewable energy accelerates, solar power has emerged as a cornerstone of sustainable development. Behind every high-performance solar farm and rooftop installation lies a critical structural component: the solar strut channel. This essential part secures solar panels, ensures optimal tilt angles for energy capture, and withstands harsh environmental conditions—making its manufacturing quality a decisive factor in the longevity and efficiency of solar projects. Our solar strut channel roll forming machine is engineered to redefine the production of this vital component, empowering manufacturers and solar contractors to meet the booming demand for reliable, cost-effective solar infrastructure.

Unlike generic roll forming equipment, our machine is tailored specifically for the unique requirements of solar strut channels—combining precision, speed, and adaptability to produce profiles that align with global solar industry standards. Whether for large-scale utility solar farms, commercial rooftop systems, or residential solar setups, our equipment transforms raw metal sheets into consistent, high-strength strut channels that form the foundation of durable solar installations.

Solar-Specific Precision for Optimal Panel Performance

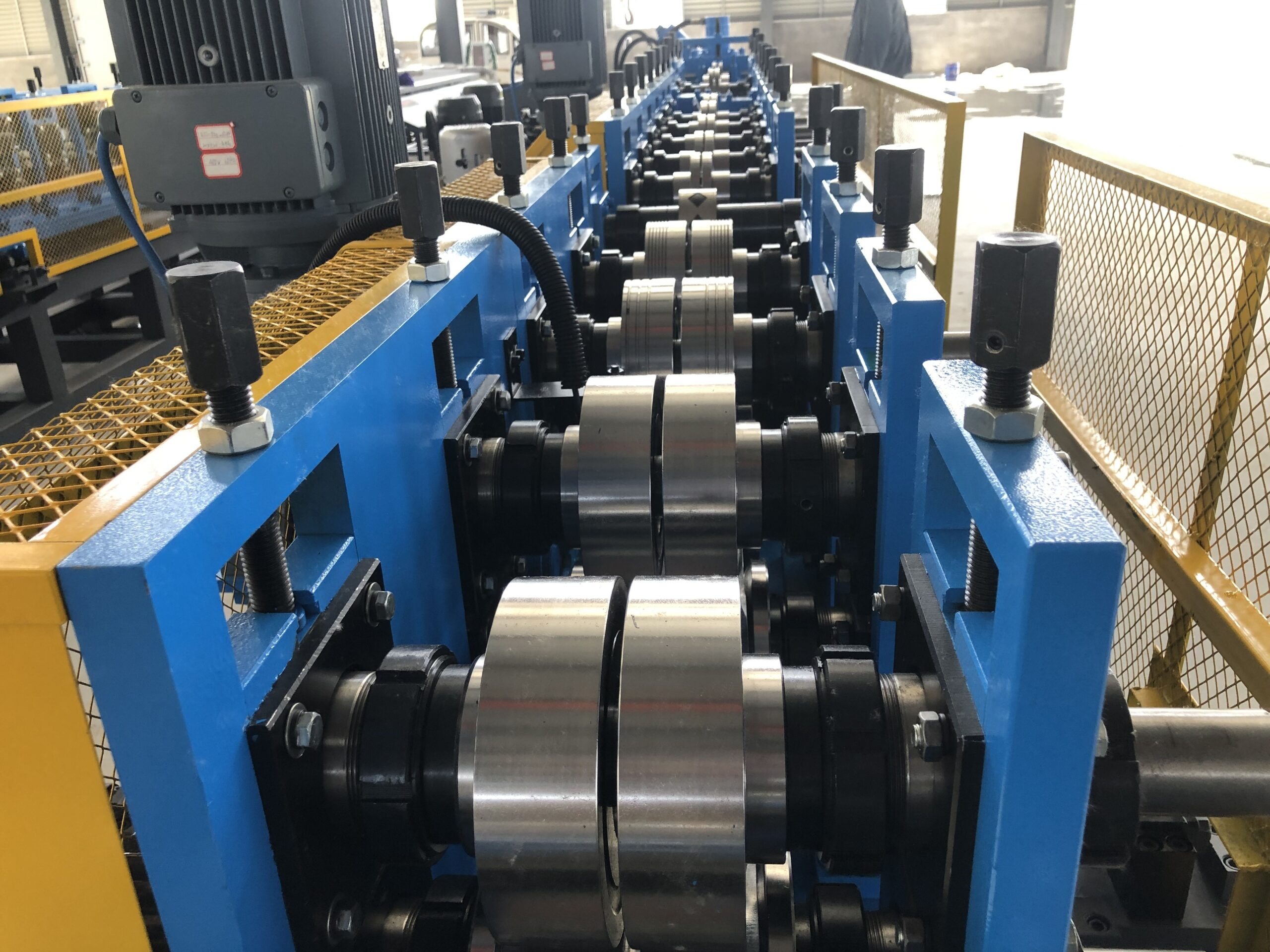

Solar strut channels require unparalleled precision to ensure proper panel alignment, which directly impacts energy output. Even a 0.5mm deviation in profile dimensions can lead to uneven panel placement, reducing sunlight absorption and compromising the structural stability of the entire array. Our solar strut channel roll forming machine addresses this critical need with an advanced CNC control system, featuring real-time position feedback and automatic calibration to deliver dimensional accuracy of ±0.15mm.

We pair this system with custom-engineered molds crafted from high-wear alloy steel. These molds are designed to produce standard solar strut channel profiles (such as C-channel, U-channel, and Z-channel) as well as custom designs tailored to unique project specifications—whether for wind-resistant coastal installations or space-saving rooftop systems.

High-Capacity Production to Meet Solar Demand Surge

What makes this high speed sustainable is the machine’s integrated automation: from automatic material feeding and leveling to precision cutting and stacking, every stage is synchronized to minimize downtime. The CNC system also supports batch production with pre-programmed profiles.

Weather-Resistant Build for Long-Lasting Solar Structures

Solar strut channels operate in extreme conditions—from scorching desert heat and UV radiation to freezing temperatures and coastal salt spray. To ensure the components they produce meet these demands, our machine is built for maximum durability and corrosion resistance. The main frame is constructed from 30mm thick high-tensile steel, welded via robotic arm technology to eliminate structural weak points, and treated with a double-layer anti-corrosion coatingto withstand harsh factory and job site environments.

All critical moving parts—including rollers, drive shafts, and cutting blades—are made from hardened alloy steel and sealed with IP67-rated components to prevent dust and moisture ingress. This robust design ensures the machine operates continuously with minimal maintenance, delivering consistent performance even in remote solar manufacturing facilities.

Material Versatility for Solar-Specific Requirements

Solar projects across the globe demand strut channels made from materials optimized for local conditions—whether corrosion resistance for coastal areas, high strength for heavy snow loads, or lightweight properties for rooftop installations. Our roll forming machine accommodates this diversity, seamlessly processing a range of solar-grade materials, including galvanized steel (GI, 120-275g/m² zinc coating), aluminum-zinc coated steel (GL/AZM), and aluminum alloy (6061-T6), with material thicknesses from 1.0mm to 3.5mm.

Galvanized and aluminum-zinc steel are ideal for most solar applications, offering exceptional corrosion resistance and cost-effectiveness. Aluminum alloy strut channels, meanwhile, are perfect for rooftop projects where weight reduction is critical, cutting structural load by 30% compared to steel. The machine’s adjustable forming pressure and speed parameters ensure optimal processing for each material, preserving surface quality (critical for pre-painted or coated metals) and maintaining profile integrity—even for high-strength steel used in wind-prone regions.

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.