Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

Roof Sheet Roll Forming Machine: Precision, Efficiency, and Durability for Your Roofing Production

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

In the dynamic world of construction and roofing manufacturing, the right equipment is the cornerstone of productivity, quality, and market competitiveness. Our Roof Sheet Roll Forming Machine stands as a testament to innovative engineering, designed to transform raw materials into high-quality, consistent roof sheets with unparalleled efficiency. Whether you’re catering to residential, commercial, or industrial roofing demands, this machine is your reliable partner to streamline production, reduce costs, and elevate your product standards.

All-Round Capability: Adapt to Diverse Roofing Needs

Our roof sheet roll forming machine is engineered with versatility at its core, capable of handling a wide range of materials, profiles, and production requirements—making it a versatile asset for any roofing manufacturing line.

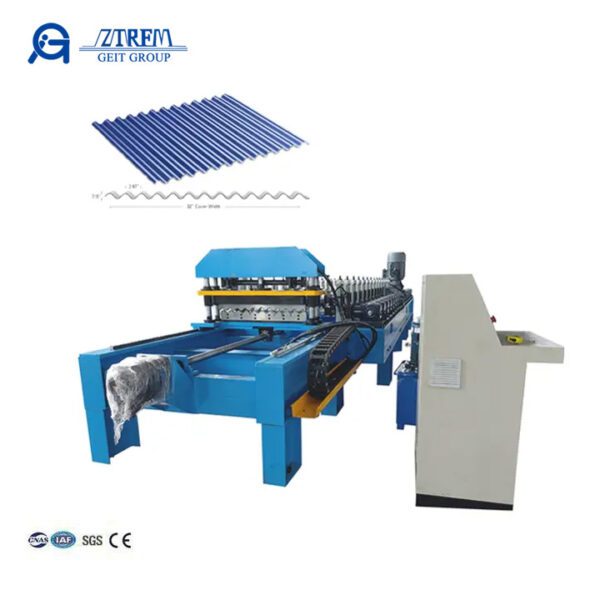

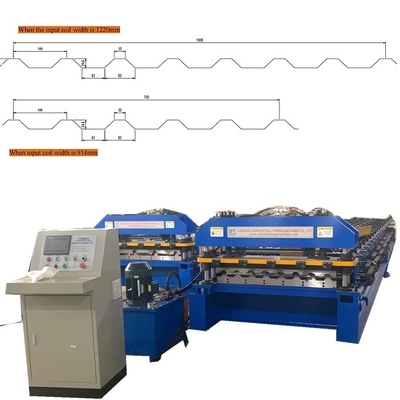

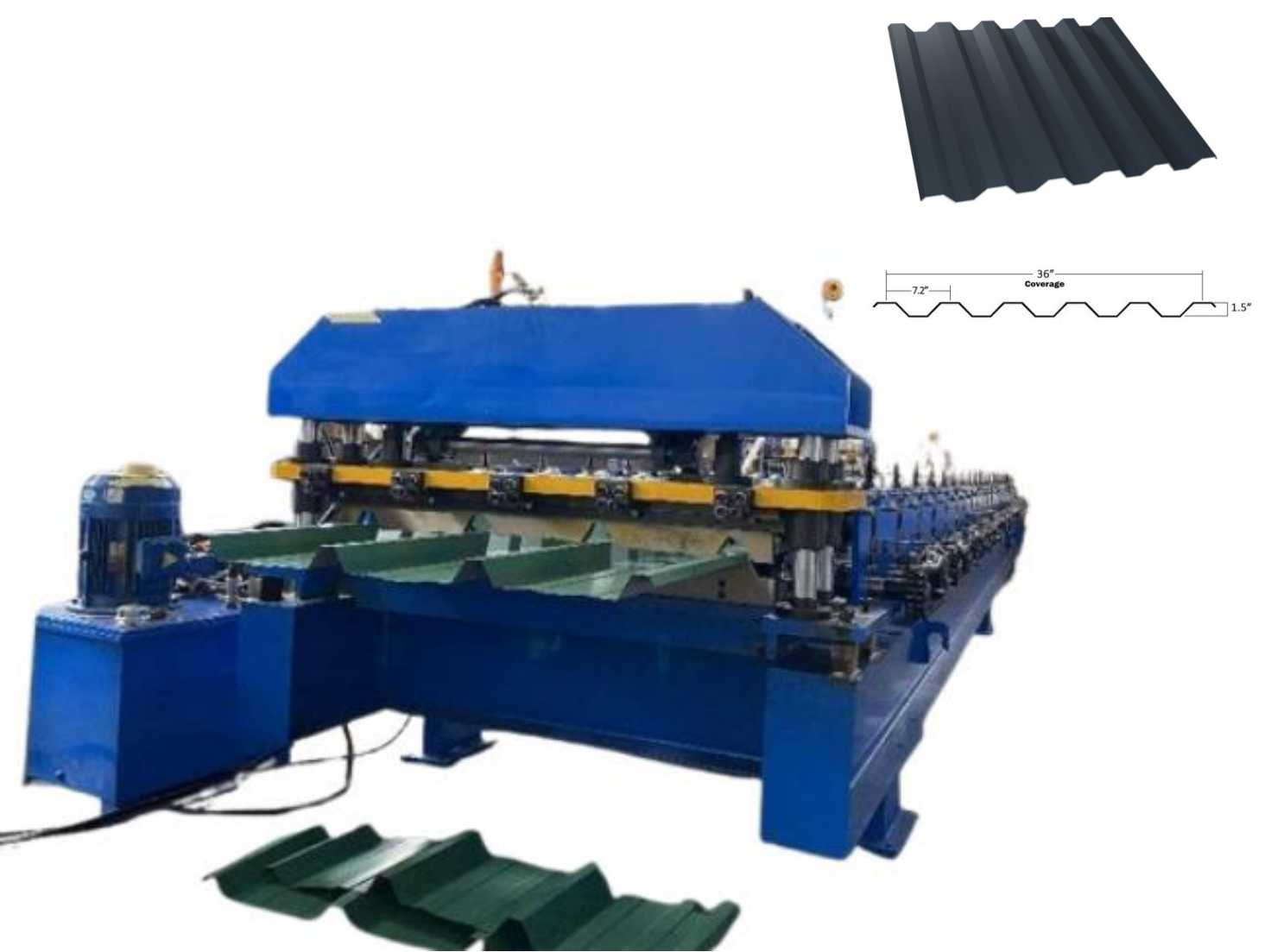

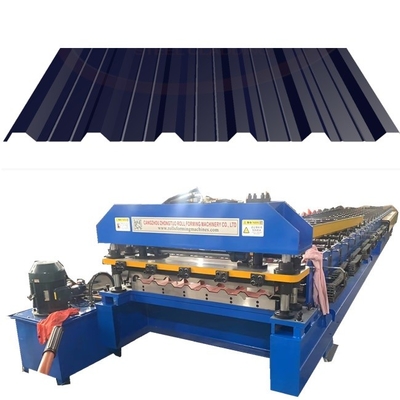

In terms of material compatibility, it seamlessly processes various commonly used roofing materials, including galvanized steel, color-coated steel, aluminum, and stainless steel, with material thickness ranging from 0.3mm to 1.2mm. This flexibility allows you to meet diverse customer demands, from affordable residential roofing to corrosion-resistant industrial roofing solutions. When it comes to profile customization, we offer tailored roll sets to produce different roof sheet types, such as corrugated roof sheets, trapezoidal roof sheets, standing seam roof sheets, and tile-effect roof sheets. Each profile maintains precise dimensions and smooth surfaces, ensuring perfect fitting during installation and enhancing the overall aesthetics of the building.

Precision Forming for Consistent Quality

The heart of our machine lies in its precision-engineered roll sets and advanced control system. Each roll is crafted from high-quality alloy steel, through heat treatment to ensure wear resistance and dimensional stability. The CNC machining technology guarantees that the roll surface has a smooth finish and accurate profile, ensuring that every roof sheet produced has uniform thickness, clear edges, and no wrinkles or defects. Additionally, the machine is equipped with a high-precision encoder and PLC control system, which real-time monitors the forming process and adjusts parameters automatically, minimizing human errors and ensuring consistent product quality batch after batch.

User-Friendly Design: Easy Operation and Maintenance

We prioritize user experience in every detail of the machine’s design, making it easy to operate even for workers with limited technical experience. The machine is equipped with a touchscreen HMI (Human-Machine Interface) that displays all operating parameters clearly, allowing operators to set production speed, sheet length, and other parameters with just a few taps. The automatic feeding, forming, cutting, and stacking systems reduce manual intervention, lowering labor intensity and improving production safety.

Maintenance is also made simple with the machine’s modular design. Key components are easily accessible, and the HMI provides real-time fault diagnosis and maintenance reminders, helping you identify and resolve issues quickly to minimize downtime. We also provide detailed maintenance manuals and video tutorials to guide you through routine maintenance tasks, ensuring the machine always operates at its best.

Global Service: Your Reliable Partner Worldwide

As a professional international trade company with years of experience in the manufacturing equipment industry, we are committed to providing comprehensive services to our customers around the world. From the moment you inquire, our team of technical experts will work with you to understand your specific production needs and recommend the most suitable machine configuration. We offer customized solutions for special profiles or production requirements, ensuring the machine perfectly matches your business goals.

Our Roof Sheet Roll Forming Machine combines precision, efficiency, durability, and versatility to help you produce high-quality roof sheets efficiently, reduce costs, and expand your business reach.

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.