Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

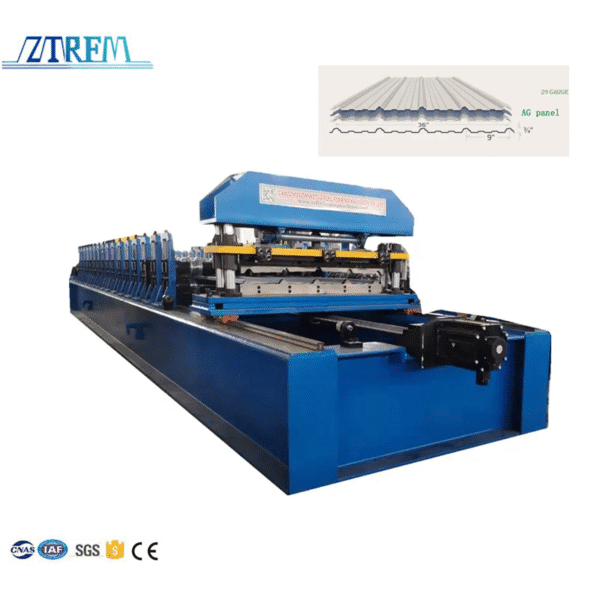

Roof Panel Roll Forming Machine: Craft High-Quality Roofing with Excellence

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

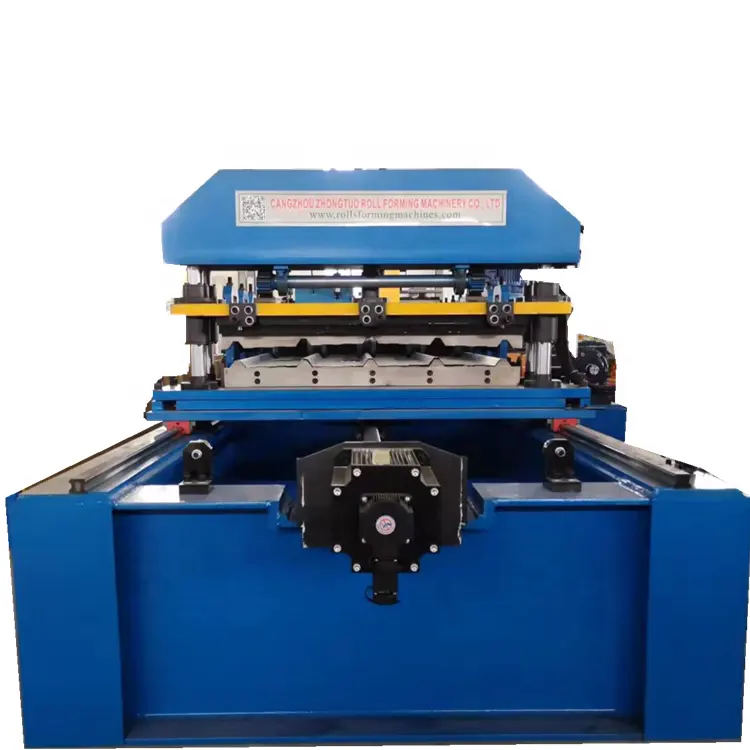

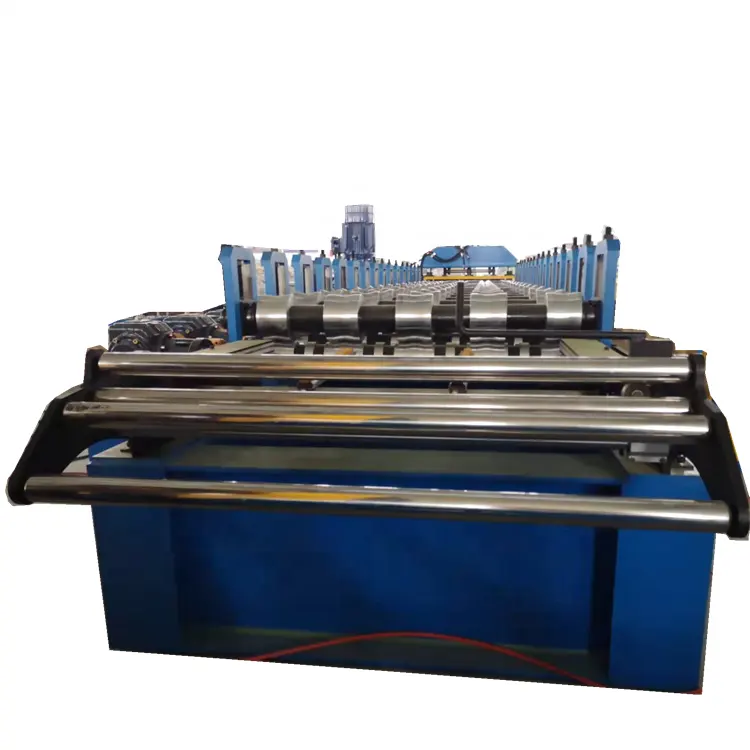

As a trusted manufacturer and supplier of metal processing equipment, we are delighted to introduce our Roof Panel Roll Forming Machine—a professional solution tailored for high-efficiency production of premium roof panels. Designed to meet the rigorous demands of the global construction industry, this machine integrates advanced technology, stable performance, and cost-saving features, empowering your business to deliver flawless roofing solutions.

Core Performances & Outstanding Advantages

Our Roof Panel Roll Forming Machine stands out in the market with its targeted design for roof panel production, boasting performances that directly address the pain points of manufacturers and advantages that create tangible value:

1. Precision Forming for Weather-Resistant Roofs

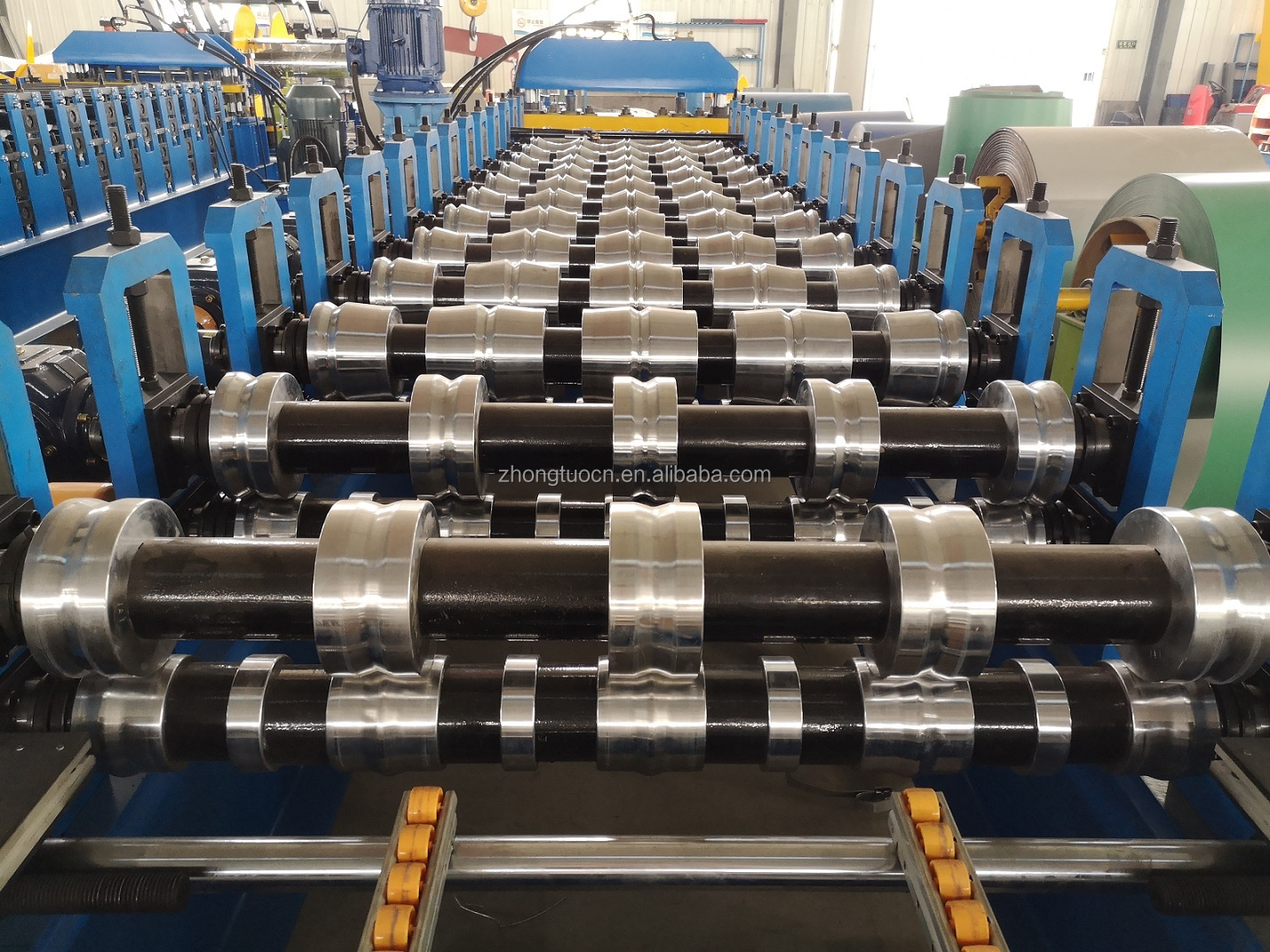

Adopting multi-pass precision rolling technology and high-precision machined rollers (surface roughness Ra≤0.8μm), the machine ensures that each roof panel has uniform wave shape, tight edge locking, and consistent dimensions. The formed panels feature excellent water tightness and wind resistance, effectively preventing leakage even in harsh weather conditions like heavy rain and strong winds. The dimensional tolerance is strictly controlled within ±0.2mm, fully complying with international building material standards.

2. High-Speed & Continuous Production

Equipped with a high-power servo motor and an optimized transmission system, the machine achieves a maximum forming speed of 20-30m/min, which is 30% higher than ordinary equipment. It supports automatic unwinding, feeding, forming, cutting, and stacking in one continuous process, with the cutting accuracy controlled within ±1mm. Whether processing galvanized steel, color steel, aluminum-magnesium-manganese alloy (0.2-1.5mm thickness), it maintains stable output, helping you handle large-scale orders with ease.

3. Versatile Customization for Diverse Demands

We recognize that roof panels vary across regions and projects. Our machine supports flexible customization of roof panel types—including corrugated roof panels, trapezoidal roof panels, and glazed tile roof panels—and parameters such as panel width (200-1000mm), wave height (15-100mm), and length (customizable on demand). It can quickly switch between different molds with a mold change time of less than 30 minutes, perfectly adapting to residential buildings, industrial plants, shopping malls, and agricultural greenhouses.

4. Energy-Saving Design & Low Operation Cost

The machine adopts an energy-efficient frequency conversion control system, which reduces power consumption by 15-20% compared to traditional models. The main frame is made of high-strength steel with anti-rust coating, ensuring a service life of over 10 years. Key components (such as bearings, motors) are from well-known international brands, minimizing failure rates. Additionally, the automatic lubrication system reduces wear and tear, lowering maintenance costs by 30% annually.

5. Intelligent Control for Easy Operation

Equipped with a 10-inch touch-screen human-machine interface, the machine allows one-key setting of production parameters (length, quantity, speed) and real-time display of production data. It has built-in intelligent protection functions—such as overload protection, material breakage alarm, and emergency stop—to ensure safe operation. The simple operation logic enables new operators to get started in 1-2 days, reducing training costs and labor intensity.

Why Choose Us?

We don’t just provide machines, but a full-cycle service package. This includes free pre-sales program design, on-site installation and commissioning, 1-year free parts supply, and 24/7 online technical support. All our Roof Panel Roll Forming Machines have obtained CE, ISO9001, and SGS certifications, ensuring smooth entry into European, American, and other international markets.

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.