Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

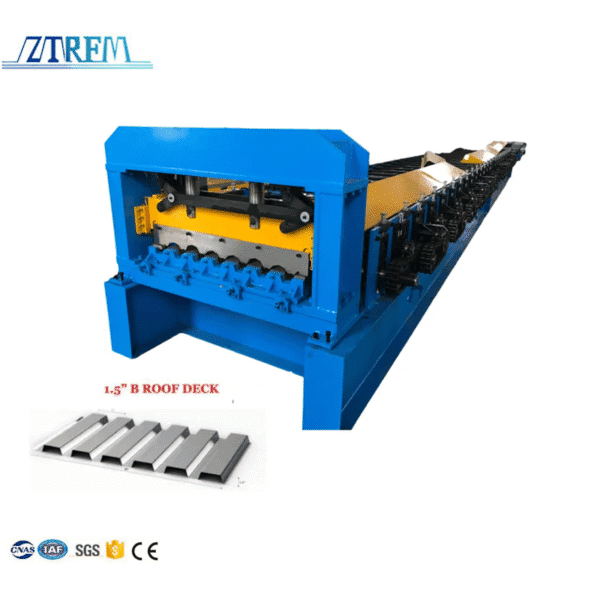

Revolutionize Your Roof Construction with Our Top - Notch Roof Deck Roll Forming Machine

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

In the dynamic realm of the construction industry, the pursuit of high – quality, efficient, and cost – effective building solutions is unceasing. Among the numerous tools and equipment that play pivotal roles, the roof deck roll forming machine stands out as an indispensable asset.

Roof decks are the fundamental structures that safeguard buildings from the elements, be it scorching sun, torrential rain, or freezing snow. A well – constructed roof deck not only ensures the safety and comfort of the building’s occupants but also significantly contributes to the overall durability and energy – efficiency of the building. This is where the roof deck roll forming machine comes into the picture. By precisely and consistently shaping metal sheets into the required profiles for roof decks, it enables the creation of robust and reliable roofing systems.

Our roof deck roll forming machine is a masterpiece of engineering, designed to meet the diverse and exacting demands of modern construction projects.

Precision Engineering

Our roof deck roll forming machine is equipped with a state – of – the – art numerical control (NC) system. This advanced NC system allows for extremely precise control over the entire forming process. With a positioning accuracy of up to ±0.1mm, it can accurately execute complex forming programs, ensuring that every roof deck profile produced meets the strictest dimensional tolerances.

The precision is further enhanced by our high – quality, custom – designed molds. Made from premium alloy steel, these molds are machined with ultra – precision grinding and EDM (Electrical Discharge Machining) techniques. They can maintain their shape and accuracy even after thousands of production cycles, which is crucial for ensuring consistent product quality. Whether it’s a standard – sized roof deck or a custom – designed one for a unique architectural project, our machine can deliver products with the exact dimensions required, minimizing waste and ensuring a perfect fit during installation.

High – Speed Production

In today’s fast – paced construction industry, time is money. Our roof deck roll forming machine is engineered to offer high – speed production capabilities, with a continuous forming speed of up to 30 meters per minute. This means that large – scale construction projects can be completed in a significantly shorter time frame.

Durable Build Quality

We understand that construction equipment needs to withstand harsh working environments. That’s why our roof deck roll forming machine is built to last. The main frame of the machine is constructed from heavy – duty steel plates, which are welded and heat – treated to ensure maximum strength and stability.

All moving parts, such as rollers, shafts, and bearings, are made from high – quality alloy materials. These components are designed to have low friction and high wear resistance, reducing the need for frequent maintenance and replacement. Even in dusty, humid, or high – temperature environments, our machine can operate smoothly and reliably for an extended period. With proper maintenance, our roof deck roll forming machine can serve you for decades, providing a solid return on your investment.

Material Flexibility

Our machine is designed to work with a wide range of metal materials, offering you maximum flexibility in your production. It can handle materials such as galvanized steel, pre – painted steel, aluminum, and stainless steel.

Galvanized steel is a popular choice for its excellent corrosion resistance, making it suitable for roofing in various weather conditions. Pre – painted steel provides an aesthetically pleasing finish right out of the machine, reducing the need for additional painting processes. Aluminum is lightweight and corrosion – resistant, ideal for applications where weight is a concern, such as in some residential and commercial buildings. Stainless steel, with its high – end appearance and superior corrosion resistance, is perfect for high – end construction projects or areas with severe environmental conditions. No matter which material you choose, our roof deck roll forming machine can process it with ease, allowing you to meet the diverse needs of your customers.

Wide – Ranging Applications

- Residential Buildings

For residential buildings, our roof deck roll forming machine offers a blend of aesthetics and functionality. In suburban neighborhoods, where homeowners often strive for a unique and appealing look for their houses, the machine can produce roof deck profiles that complement various architectural styles. Whether it’s a charming cottage – style home with a pitched roof or a modern – designed bungalow with a flat – topped structure, our machine can create the perfect roof deck.

The use of high – quality materials like pre – painted steel or galvanized steel, which our machine can handle with ease, ensures that the residential roofs not only look great but also last for decades. The pre – painted steel can come in a variety of colors, from classic earth tones to bold, contemporary hues, allowing homeowners to express their personal style. Moreover, the precision – formed roof decks provide excellent water – shedding capabilities, protecting the interior of the home from leaks and water damage during heavy rainstorms. This means that families can enjoy a dry and comfortable living environment all year round, without the worry of costly roof repairs.

- Commercial Projects

Commercial projects have stringent requirements when it comes to roof strength and durability, and our roof deck roll forming machine is up to the task. In large – scale shopping malls, industrial – style warehouses, or multi – story office buildings, the roof decks need to withstand heavy loads, including the weight of HVAC systems, rooftop gardens (in some cases), and potential snow accumulations in colder climates.

Our machine produces roof decks with robust profiles that can bear these heavy loads. The use of high – strength steel materials, such as thick – gauge galvanized steel or stainless steel, ensures that the roofs are extremely durable. For example, in a large shopping mall, the roof deck needs to support the weight of multiple air – conditioning units and exhaust fans. Our precision – formed roof decks, made with the help of our advanced roll forming machine, can provide the necessary structural integrity. Additionally, the high – speed production capabilities of our machine enable quick completion of large – scale commercial roofing projects, minimizing disruptions to business operations during construction.

- Industrial Facilities

Industrial facilities, such as factories and manufacturing plants, require reliable roofing solutions, and our roof deck roll forming machine plays a crucial role in providing them. These facilities often have large, expansive roofs that need to be constructed efficiently and cost – effectively.

Our machine can produce long – span roof decks, reducing the need for multiple joints and seams. This not only enhances the overall structural stability of the roof but also minimizes the risk of leaks. In industrial settings, where there may be vibrations from heavy machinery, a well – constructed roof deck is essential. The durable build quality of the roof decks produced by our machine, with their high – strength materials and precise forming, can withstand these vibrations over time. For instance, in a steel – manufacturing plant, the constant vibrations from the production equipment could potentially damage a poorly constructed roof. However, the roof decks formed by our machine can endure these vibrations, ensuring the long – term integrity of the building and protecting the valuable equipment and inventory inside.

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.