Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

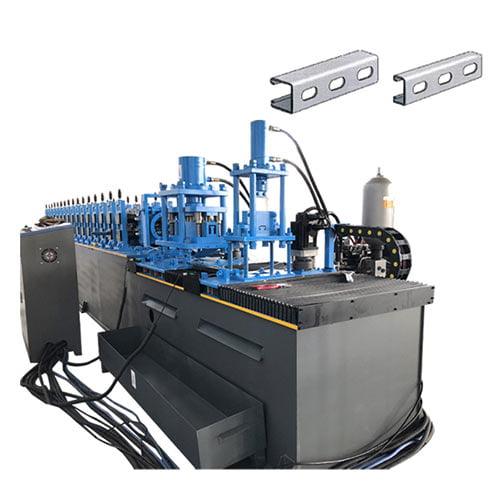

Overall photo of the machine

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc. Strut channel has been using for many years while installing solar power. The biggest advantage of solar strut channel is that it helps in the construction and easily connects the length together and other items, by using different strut fasteners. Strut channel can get jointed easily and quickly with minimal tools and labor. So in returns reduces the overall costs of the application. A strut channel installation can be easily modified or added to anywhere if needed.

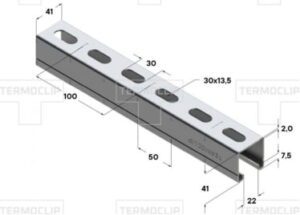

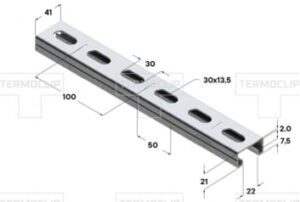

Above is strut channel profile drawing for your reference, one machine can produce two kinds of sizes with holes punching. The standard dimension is 21*21 and 41*21 mm

Remark: The two dimensions can be produce on one machine by adjust the roller spacers manually, we will provide drawing and video to teach customer how to adjust roller spacers.

The machine working flow is uncoiling—feeding material—roll forming—tracking punching—tracking cutting—product collect.

Here introduce some of our strut channel roll forming machine features to you:

1. The machine speed reach 25 m/min, we design the punching device after roll forming, prevent the holes stretcher strain . The punching device design is tracking cutting with servo motor control, very stable. The punching mold can punching 10 holes one time. The punching and cutting is working at the same time.

2. The main power of the machine adopt 5.5 kw*2 motors, save power.

3. The roller material is Cr 12 MOV with quenched treatment. Ensure when the machine running in a high speed, will not influence to its hardness,strength and service life.

4. The cutting part use Cr 12 material. This is high quality material, high hardness and strength. The servo motor control the tracking cutting.

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.