Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

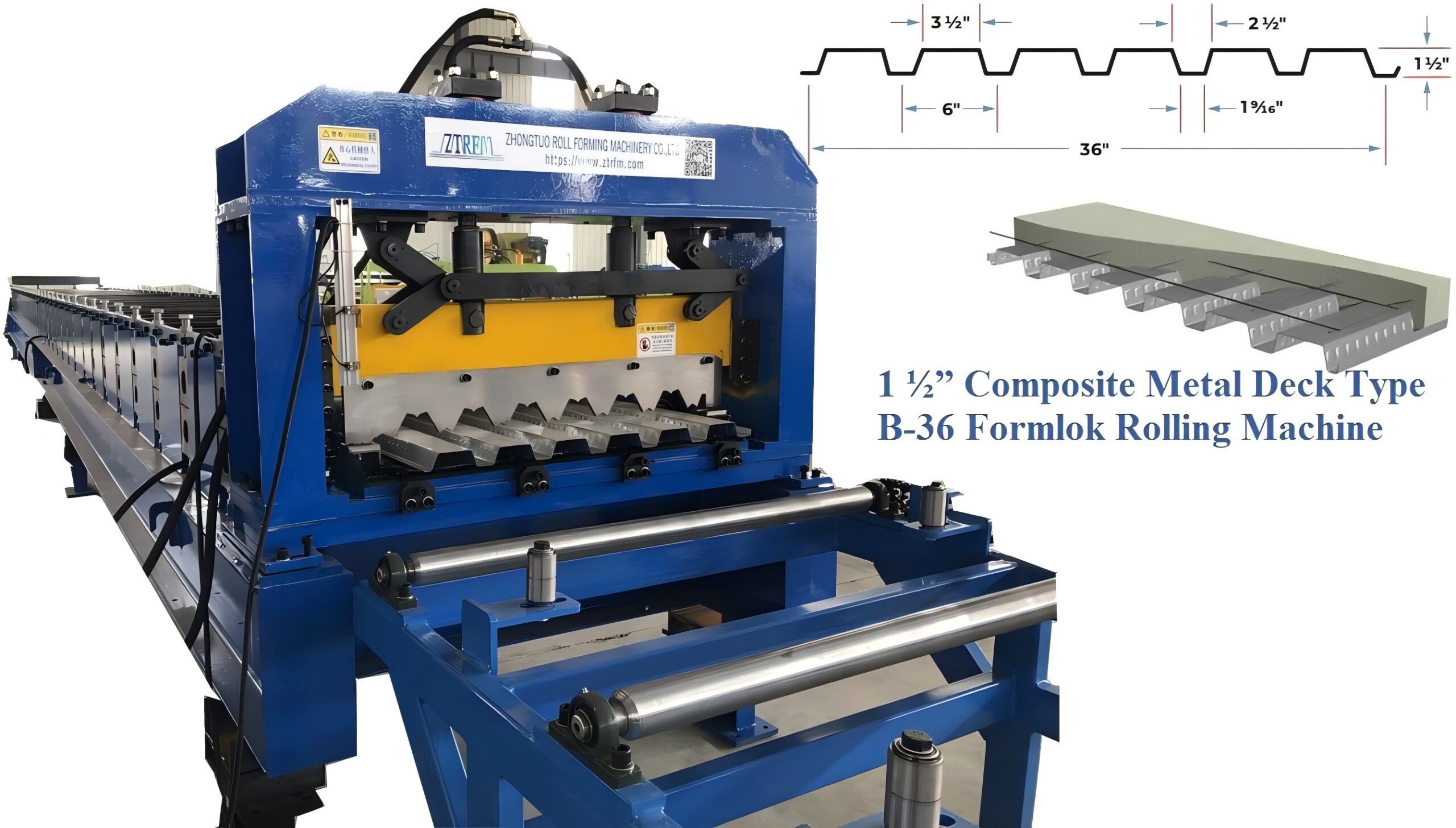

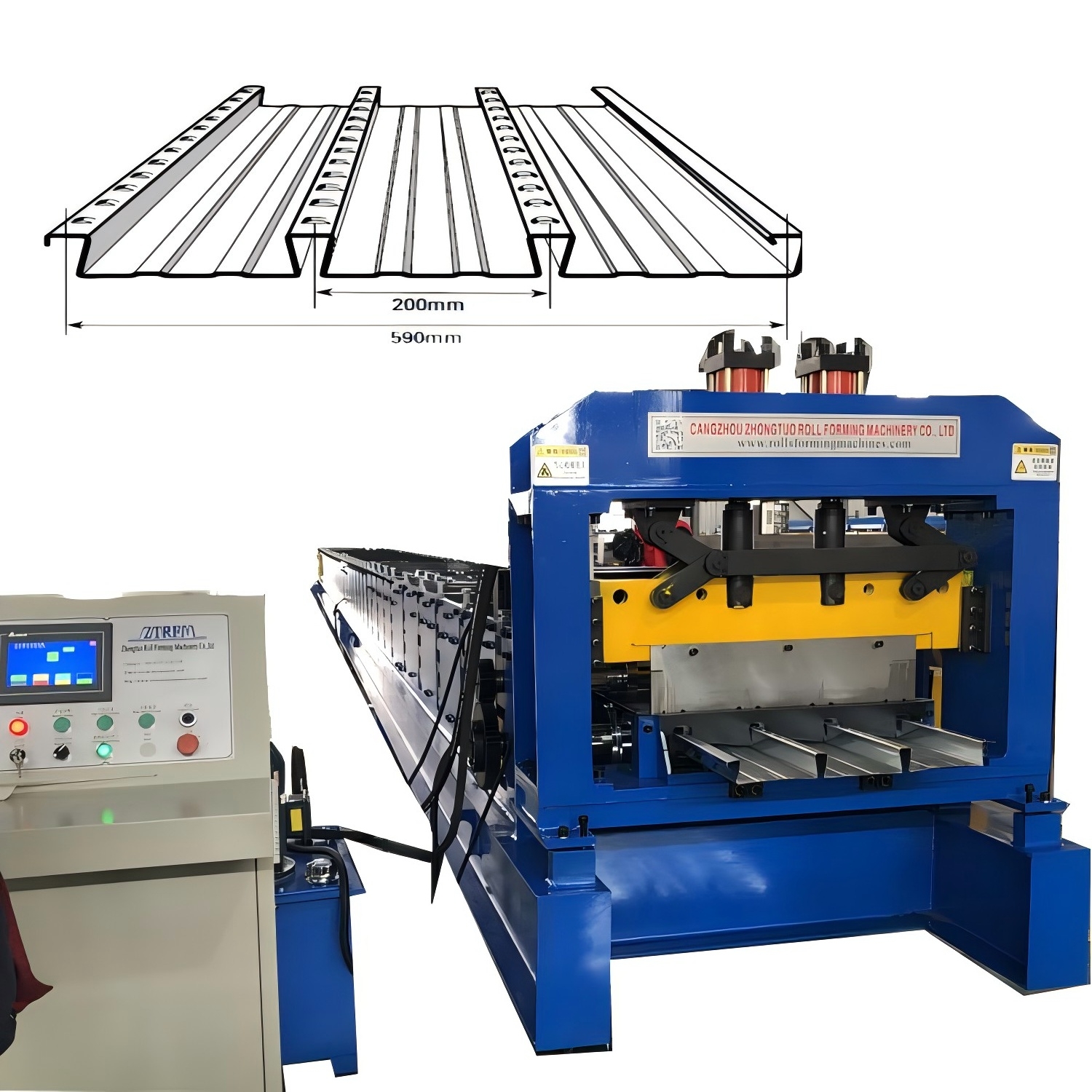

Metal Decking Sheet Machine: High-Speed Production for Durable Steel Decking Solutions

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

As a professional manufacturer and supplier of roll forming equipment, we are committed to delivering top-tier solutions for the construction industry. Our Metal Decking Sheet Machine is specially developed to produce high-performance metal decking sheets—essential components for floor, roof, and wall systems in commercial, industrial, and infrastructure projects. This machine integrates stability, efficiency, and versatility to help you capture more market opportunities.

Core Functions: Versatile Production for Diverse Needs

Our Metal Decking Sheet Machine is designed for automated, continuous production of various metal decking profiles, adapting to different construction scenarios. Its key functions include:

Multi-Profile Forming: Capable of producing composite floor decks, roof decks, and wall cladding decks (e.g., B deck, N deck, trapezoidal deck) by changing molds, meeting diverse project specifications.

Automated Coil Processing: Integrates coil uncoiling, leveling, feeding, forming, and cutting into one workflow, converting 0.8-3.0mm thick steel coils (galvanized, color-coated, or plain steel) into finished sheets seamlessly.

Precision Customization: Supports adjustable sheet lengths (2m-12m) and widths (600mm-1200mm) via PLC control, with cutting accuracy up to ±1mm to fit on-site construction requirements.

High-Speed Continuous Operation: Synchronized mechanical systems ensure stable production at 10-30 meters per minute, avoiding interruptions and boosting output.

Standout Advantages: Empower Your Production Efficiency

Compared with conventional equipment, our Metal Decking Sheet Machine offers distinct advantages that enhance your competitiveness:

Superior Product Quality: Forming rolls made of high-quality alloy steel machining ensure consistent profile shape and smooth surface, no warping or burrs, meeting AISI, DIN, and GB standards.

Intelligent & User-Friendly: 7-inch touchscreen PLC system enables one-click parameter setting, real-time production data tracking, and fault alarm, reducing training costs for operators.

Cost-Saving Performance: Automated production cuts labor demand by 70%; precise cutting and material feeding reduce waste to less than 0.5%, lowering raw material costs significantly.

Robust Durability: Heavy-duty steel frame with anti-rust treatment, wear-resistant transmission parts, and sealed bearings ensure a service life of over 10 years, with average annual downtime less than 8 hours.

Fast Mold Changeover: Modular mold design allows switching between profiles in 40 minutes, supported by professional tools, improving adaptability to small-batch, multi-variety orders.

Our Commitment: Your Trusted Partner

With 20 years of experience in roll forming technology, we provide more than just machines—we offer comprehensive support to global clients:

Customized Solutions: Tailor machine configurations (mold design, speed, control system) based on local construction standards and your production scale

Global Certification: All machines pass CE, ISO 9001, and SGS certifications, complying with import requirements of Europe, Southeast Asia, Africa, and the Americas.

Our Metal Decking Sheet Machine has been exported to 60+ countries, trusted by over 1,200 construction material manufacturers. Whether you’re expanding production or upgrading equipment, we’re here to help you achieve higher efficiency and profits.

Contact us now to get a free technical proposal and customized quotation—let’s build success together!

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.