Over 24 Years Experience & Knowledge International Standards,

Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

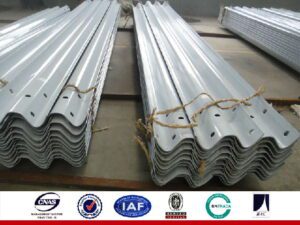

Highway guardrail roll forming machine

Cangzhou Zhongtuo Roll Forming Machinery Co.,Ltd comes from Hebei-China. It is a manufacturer dedicated to design and manufacture.

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

For more information, delivery time and prices, please mail us!

1.Profile drawing:can design as customers’ request

2.Process flow

Uncoiling–Adjustable feeding guide–straightening–punching&cutting–powered run-out table–roll forming–finished product

3.Main technical parameters

- Feeding section with guide

- Nine leveling rollers: four up and five down

Material : 45# steel

- Feeding roller (Side roller) : a pair

- Hydraulic punching

- Shaft material & shaft outer diameter

45# steel adjustable treatment,

- Rollers material: GCR15, quenched treatment

- Stations: 16 steps of main rollers

- 8. Transmission: gear box

- Forming speed: 10-15/min

- Voltage, Frequency,Phase: 380V,50Hz,3Phase

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

1.communication:confirm buyer's requirement.

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

5.packing and delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

We are honored to cooperate extensively with many

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.

0

ISO9001 and CE Approved

We own our self-brand ztrfm, professional design team And Technicians.

0

Countries Clients

Popular products with users and highly praised.

0

One-Stop Solutions

from accessories to molding machines, solving the complexity of your procurement.

0

Engineer Team

We have strong engineer team of more 20 People, we will give more accurate and fast solution.