Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

High-Speed Trapezoidal Roof Tile Forming Machine

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

Through innovative technology architecture and intelligent control system, this equipment provides one-stop solution for construction contractors and professional purchasers.

The equipment uses high quality materials and precision manufacturing process to ensure that each trapezoidal roof tile meets the high standard quality requirements, while greatly improving production efficiency to meet the urgent schedule requirements of various large engineering projects.

Technical parameters

Core Specifications

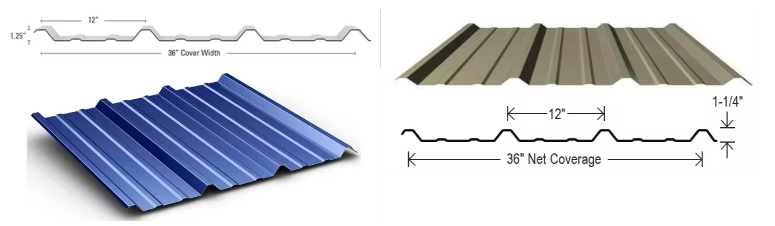

Forming materials: PPGI, GI, AI

Thickness range: 0.3-1.0mm

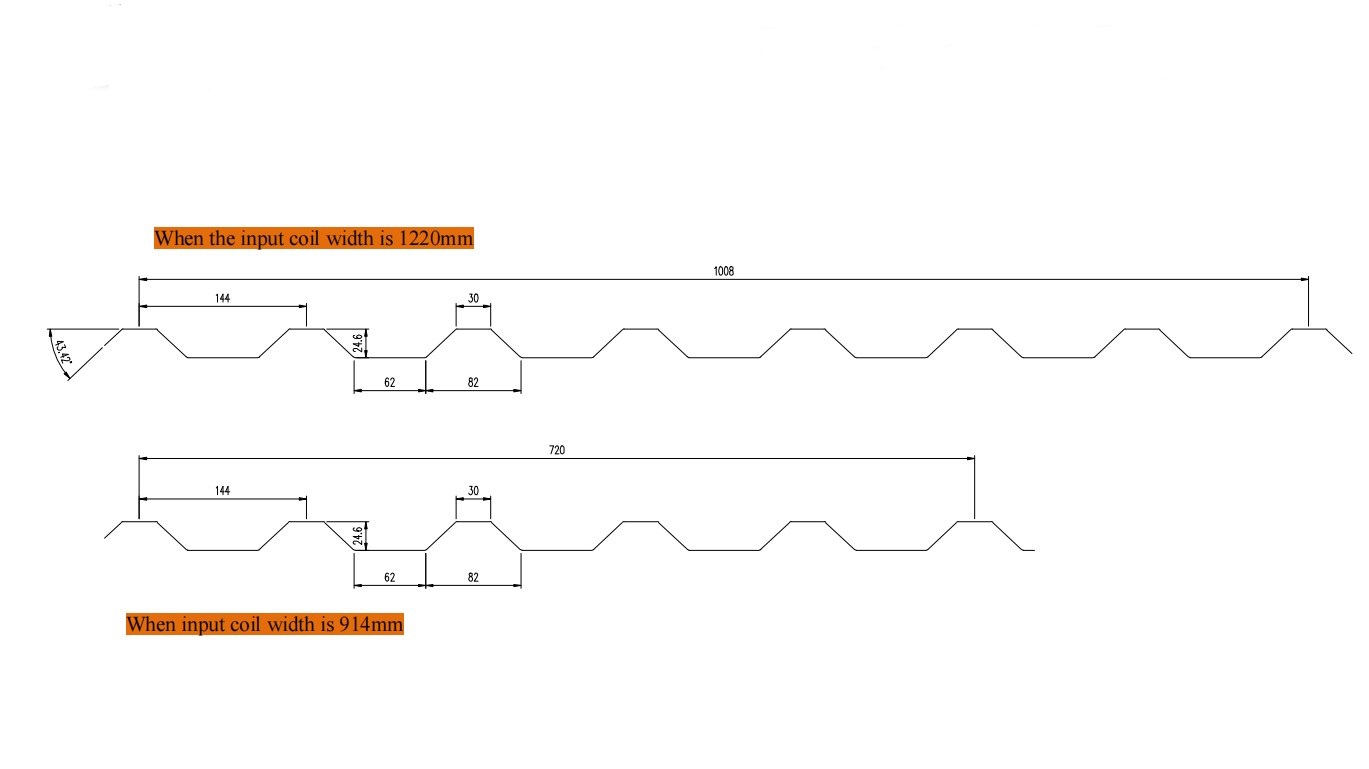

Width: 1000mm/1250mm (customizable)

Roller stand configuration: 26 rows (customizable)

Performance index

Forming speed: 0-60m/min (typically under 30m/min for conventional equipment)

Cut tolerance: ±1mm

Motor power: 5.5KW

Hydraulic power: 7.5 kW

Serviceability

This equipment achieves a groundbreaking 0-60m/min molding speed, effectively addressing schedule pressures in large-scale engineering projects. In a major industrial plant construction project, it significantly boosted overall efficiency. The high-speed operation not only saves time but also generates greater commercial value for the client.

Reliable and stable performance

The equipment replaces traditional chain drive systems with a gear box transmission, combined with a robust cast iron structural design that significantly reduces failure rates. According to 2024 customer feedback data, the equipment achieves an average 1,500 hours of trouble-free operation, far exceeding industry averages. This stability ensures uninterrupted production processes, preventing project delays and additional costs caused by equipment failures.

Precision Control

The Delta PLC control system enables fully automated production management, precisely controlling product length, quantity, and batch sizes. Omron’s high-precision encoder maintains cutting tolerances within ±1mm, meeting the most stringent construction standards. The system supports parameter presets and automatic switching, facilitating rapid conversion between different product specifications to enhance production line flexibility.

Personalized configuration

We understand that each project has unique requirements, so we provide comprehensive customized services. Key parameters such as roller station configuration, forming width, and control system functions can be adjusted according to customer requirements.

Technical support

Our professional engineering team provides full-process technical support, covering equipment selection, installation, commissioning, and operation training. Ensure long-term and efficient operation of equipment through regular remote diagnosis and preventive maintenance.

Epilogue

The high-speed trapezoidal roof tile forming machine represents the latest technological achievements in the field of roof building materials manufacturing, which not only solves the pain points of traditional production, but also leads the industry to the direction of intelligent and efficient development.Through technological innovation, we are committed to delivering superior and eco-friendly solutions for the global construction industry, empowering clients to gain a competitive edge in today’s fiercely competitive market.

Choosing our high-speed trapezoidal roof tile forming machine is not just about selecting equipment, but also about choosing a reliable long-term partner. Let us join hands to build a bright future for roofing construction.

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.