Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

High speed rolling shutter machine 35 meter per minute

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

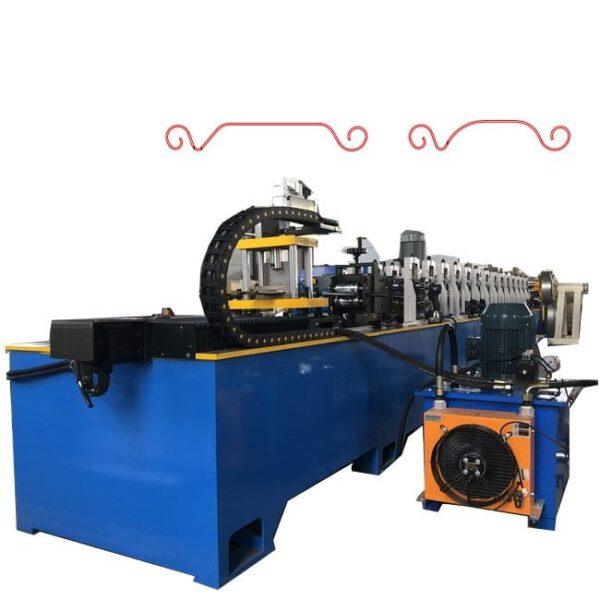

High speed rolling shutter machine 35 meter per minute

High speed rolling shutter machine 35 meter per minute is designed to make the rolling shutters in batch fully automatically with embossing. The Roller shutter is a door that is connected in series with multi joint movable door pieces and rotates up and down in the fixed slide way with the roller above the door as the center. Roller shutter is usually widely used in shops.

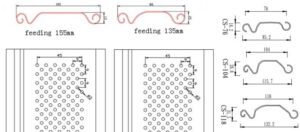

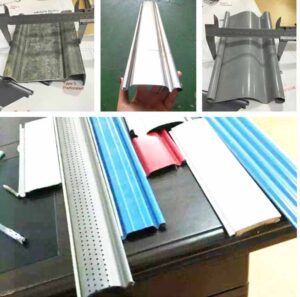

The Roller shutter, like the wall, plays the role of horizontal separation. It is composed of many parts, such as the shutter, base plate, guide rail, support, reel, box, control box, rolling door machine, limiter, door header, manual quick release switch device, button switch and safety device. It is generally installed at the location where wall separation is inconvenient. Here are some drawing profiles for your reference:

For the profile making, one machine we can design it either with punching or without punching. One machine we can design it either with embossing or without embossing.

High speed rolling shutter machine 35 meter per minute:

Advantages of high speed rolling shutter door machine:

- The machine we designed using gearbox transmission for long time to use and small noise.

- The machine we use the molding frame so even if in high speed working, it still steady.

- Using servo tracking shearing system to reach the high speed, non-stop shearing and cutting.

- More type embossing rollers, you can choose to use which type embossing.

- With oil cooling system to make sure the rollers are cool when high speed working.

| Packing list for shutter door roll forming machine | ||||

| Part 1 | 3 T hydraulic decoiler | set | 1 | Automatic |

| Part 2 | Roll forming system | set | 1 | Gear transmission |

| Part 3 | PLC control station | set | 1 | Delta brand |

| Part 4 | Hydraulic system | set | 1 | YUKEN STANDARD |

| Part 5 | Product collect table | set | 1 | Manual/3m length |

| Part 6 | Extra cutting blade and embossing roller | set | 1 | |

More parameters of the high speed rolling shutter door machine:

Rolling shaft: Shaft material: 45# steel

Shaft diameter: 50 mmTempering treatment

Roller Roller : material: Cr12 Quenched treatment

Rolling station :14 stations

Machine frame:Molding frame of thickness 35 to 45mm

Machine body:steel plate welded with grinding

Bearing :Chinese famous brand Harbin Work power 7.5 kw

Transmission: By Gear box

As to the PLC, you can chose the portable type or cabinet type:

Here are more types shutter designs for your reference:

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.