Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

High Speed Corrugated Roofing Roll Forming Machine

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

High Speed Corrugated Roofing Roll Forming Machine

High Speed Corrugated Roofing Roll Forming Machine is for making the corrugated roofing sheet in batch fully automatically, the speed can reach 50 to 60 meter per minute. The speed increased up by Invert and double hydraulic system. All Rollers are made of high quality material and gone under Taiwan vacuum heat treatment which makes them stronger and have long lifespan.

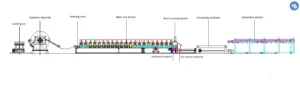

Take the following drawing profiles to show how the machine is designed:

High Speed Corrugated Roofing Roll Forming Machine features:

1.To make sure of the accuracy, all rollers are custom designed and machined precisely by state-of-the-art CNC machines placed inside the factory. Rollers are hardened through vacuum heat treatment (Taiwan technology) and chrome plating.

2.For the machine, all we use the the molding frame thickness of 45mm. Frame are made by hardened steel and connected by bolts which make machinery sturdy, easy to maintain, and avoid deformation while operating.

3.As to the shearing part, we do the cutting from down to top and then it will not damage the surface of raw material. Shearing (Cutting) made by S50C or SKD, gone through vacuum heat treatment to have a longer lifespan.

4.For the Control system with intelligent PLC and HMI touch-screen helps to operate machine simply and to create identical rollformed steel sheets which present your exact specifications.

There are more details pictures of High Speed Corrugated Roofing Roll Forming Machine for your reference:

Why our Hi-Speed Corrugated Galvanized Iron Roofing Roll Forming Machine differ from others:

1) Easy in installation and maintenance.

2) Hardened structural steel and components provide long life and safe operational stability.

3) Adopting advanced world famous brand components in controlling parts, electric parts and operation parts.

4) Running in an automation, high durability and stability.

5) Compact design, meet custom demands.

For this machine, if you want to know more information, please contact us at any time.

Corrugated Roof Sheet Machine video channel

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.