Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

High quality bending cold forming Angle bar making machine can customize multiple angles

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

This High speed Rotary punching L corner bead wall angle L trim roll forming machine is with high speed, the speed can achieve as high as 45 meters/min. It is with a rotary punching system. this rotary punching is a kind a rolling punching system. this rotary punching system is fast then the electric punching system.

The machine need two mold to produce different size. And we also improve the machine with no stop cutting,the totally speed will be 45m/min.

Also the High speed Rotary punching L corner bead wall angle L trim roll forming machine main machine body is with a servo power, so that to make tsure the speed of the machin running.

corner bead L trim corner protector steel angle making machine included below sections:

Manual decoiler,Feeding material into machine ,Roll forming machine ,Measure length ,Hydraulic cutting ,Receiving table

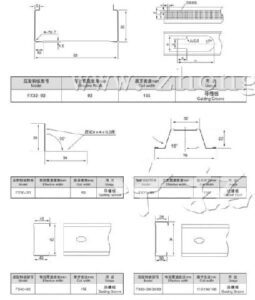

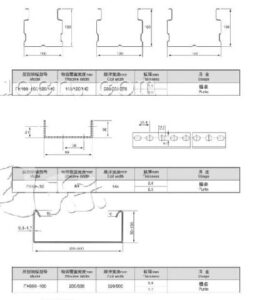

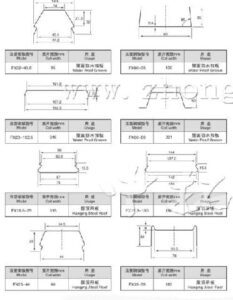

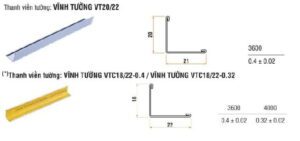

Profile drawing for your reference :

Below is some specifications of the main roll forming section:

1 machineForming steps9 stations

2 Shaft diameter40mm

3 Design typeMemorial arch frame type

4 roller materialGCr12MoV

5 shaft material45# steel

6 Work speed10-25m/min

7 TransportBy gear

8 Power of main machine3 kw

Below are some machine detail picture for you:

We design and make this machine according to customer’s require. ZHONGUO can design the combined machine to make different kinds of profiles of L and Omega, and C and U channels, which are used for suspended drop ceilings.

ZHONGTUO also provided with high quality after sales service as below:

- Warranty: Support the technology all the life. And the machine broken because of quality, we can change the broken part for free within one year.

- Training: If you come to our factory,we can teach you for free.

If you need technician go foreign, the buyer need pay the cost for visa, hotel, ticket, food and others, and buyer need pay the technician USD50/day for salary.

There need one technician. Training time will be one week.

The profiles of the c u w T channel omega roll forming machine

The difference between the c u w light steel channel omega roll forming machine and the c z u purlin roll forming machine

1 The biggest defference between the c u w profile stud and purlin is that the thickness is different. The C U H purlin often used as the support of the building, because it stree heavy.

The thickness range of the purlin is :2.0-4.0mm the thickness of the c u w L light steel stud is :0.3-0.8mm

so the C Z U purlin roll forming maQchine need much heavy and thick configuration.

2 The c z u w channel stud are often used in ceiling and wall structure. The C Z Purlin and U purlin are used for supporting the ceiling from the ground.

3 The difference between the c z u w channel stud furring and the cz u purline is the thickness, so the cz u purline machine is mu stronger , with big electric power and thick blade which can cut the purlin .

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.