Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

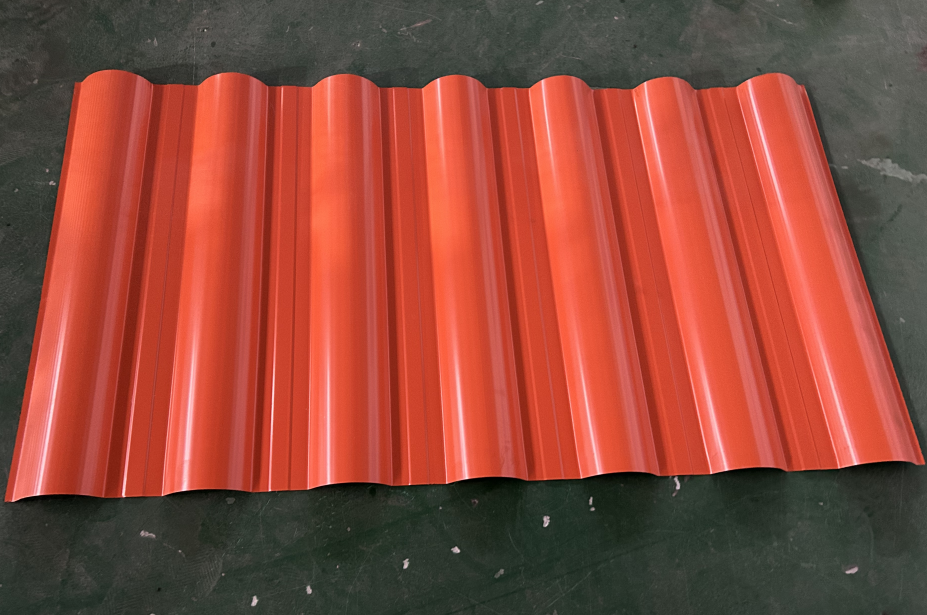

High Quality and High Precision Glazed Tile Molding Machine

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

In architectural practice, roofing serves as a critical envelope structure that not only shapes a building’s visual identity but also determines its waterproofing, thermal insulation, heat resistance, and durability. In this context, roofing forming technology plays a pivotal role. Cutting-edge forming techniques enable roofing materials to achieve precise geometries and superior performance, thereby better fulfilling diverse architectural requirements.

An in-depth analysis of the working principle

The working principle of the High Quality and High Precision Glazed Tile Molding Machine embodies sophisticated mechanical design and efficient production concepts. The process begins with metal sheet feeding, where sheets are precisely positioned on the feeding device. This device then delivers the sheets into the machine at a steady, uniform speed.

Upon entering the equipment, the metal sheet undergoes a critical rolling and shaping phase. Inside the machine, multiple sets of rollers are arranged in a stepped configuration, resembling a meticulously designed production line. These rollers work in coordination to gradually apply pressure to the sheet, continuously bending it into the preset shape and dimensions. During this process, the sheet evolves from its initial flat state into a glazed tile roof profile with specific curvature, ridges, and valleys through the action of successive rollers. Each set of rollers is precisely engineered and manufactured to ensure uniform and stable pressure application, guaranteeing dimensional accuracy and consistent shape in the final glazed tile.

Upon completing the roller pressing process, the sheets proceed to the fixed-length cutting stage. The system features a high-precision cutting mechanism that precisely cuts the continuously formed glazed tile sheets according to preset length parameters, producing standardized lengths tailored to practical applications. This seamless process, driven by automated control and coordinated mechanical components, achieves efficient and accurate conversion from metal sheets to finished glazed tile roofing products, demonstrating exceptional production efficiency and technical expertise.

Design and Construction Highlights

The High Quality and High Precision Glazed Tile Molding Machine boasts remarkable design and construction features. As the core component, the rollers are made of premium #45 steel with polished and chrome-plated surfaces achieving HRC55-60 hardness. This material and treatment process provide exceptional wear and corrosion resistance, ensuring stable performance during prolonged high-intensity operation while effectively reducing product quality issues and maintenance downtime caused by roller wear. The rollers’ unique design also addresses the forming requirements of glazed tiles, with their surface geometry and dimensions precisely engineered to accurately shape complex tile configurations, providing a solid foundation for high-quality product formation.

The equipment’s robust and stable frame is constructed from high-strength steel. Its base frame employs 35# H-beam steel, which delivers exceptional load-bearing capacity and deformation resistance to withstand operational forces, ensuring stability during high-speed operation and extended use. The 16mm-thick structural plates further enhance the frame’s strength, enabling adaptation to diverse complex working environments and production requirements. Moreover, the design prioritizes user-friendly operation and maintenance, with logically arranged components that simplify daily operations, monitoring, and upkeep. This approach significantly boosts production efficiency while extending the equipment’s service life.

Outstanding features and advantages

High precision molding, superior quality

In roofing engineering, product precision and quality directly determine a building’s overall performance and longevity. The High Quality and High Precision Glazed Tile Molding Machine delivers high-precision forming through its advanced manufacturing techniques and precision control systems, providing reliable quality assurance for roofing projects.

The equipment features precision-engineered rollers meticulously designed to control every detail of metal sheet forming. With ultra-precise dimensional tolerances, each glazed tile roof panel achieves perfect consistency in critical measurements like ridge height, valley depth, and width, fully complying with industry standards and client specifications. This high-precision forming capability not only ensures a sleek, uniform roof appearance but also significantly enhances waterproofing, wind resistance, and thermal insulation. For instance, precise panel alignment eliminates seams between sheets, reducing rainwater leakage risks. The uniform ridge and valley patterns strengthen the roof’s structural integrity, making it more resilient against strong winds and snow accumulation. This design dramatically extends the roof’s lifespan while lowering long-term maintenance costs.

Efficient production, time saved

In today’s fast-paced construction market, production efficiency is a key factor in corporate competitiveness. The High Quality and High Precision Glazed Tile Molding Machine delivers exceptional efficiency, helping businesses stand out in the cutthroat competition.

The equipment employs advanced continuous forming technology, enabling metal sheets to undergo high-speed continuous roll forming within the machine without frequent stops or adjustments, significantly shortening production cycles. Its forming speed can be flexibly adjusted according to actual production needs, reaching up to 15 meters per minute, which substantially improves production efficiency compared to traditional roof forming equipment. Additionally, the automated control system integrated into the equipment achieves full automation throughout the entire process—from sheet feeding, forming, cutting to finished product collection—reducing manual intervention, lowering labor intensity, and further enhancing production efficiency. Operators only need to set relevant parameters on the control panel, after which the equipment automatically operates according to preset programs, greatly improving production accuracy and stability. For instance, in large-scale roofing projects, this equipment can rapidly produce large quantities of glazed tile roof panels to meet urgent engineering demands, ensuring timely project delivery and helping enterprises gain excellent market reputation and economic benefits.

Multiple application scenarios

The High Quality and High Precision Glazed Tile Molding Machine, with its outstanding performance and broad material adaptability, demonstrates strong application potential in various construction projects. As an indispensable key equipment in the construction industry, it is widely used in commercial buildings, residential buildings, and industrial plants.

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.