Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

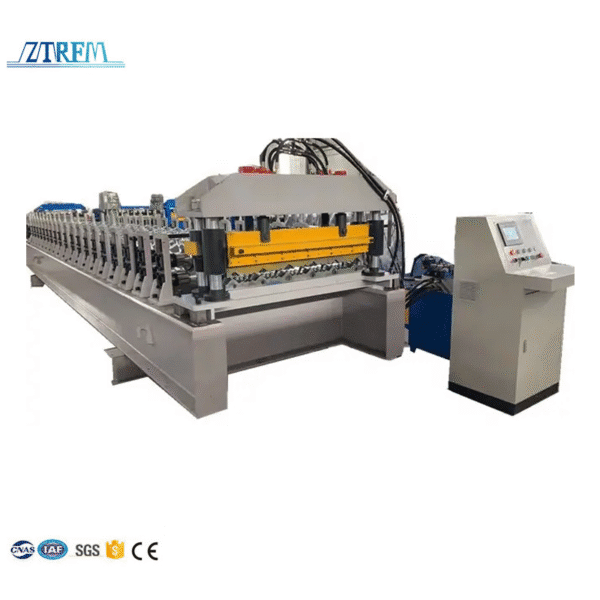

High Efficiency Color Glaze Roof Panel Roller Forming Machine

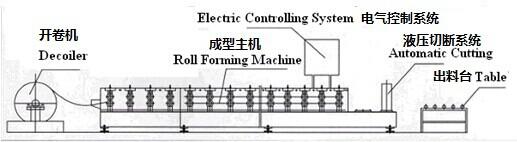

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

The high-precision forming system ensures that each roof panel has the same size and smooth surface, and the fully automated process significantly improves manufacturing efficiency to meet the high strength and durability requirements of modern roofing materials.

Technological superiority

The equipment features an intelligent PLC control system that enables precise parameter adjustment and fully automated operation, achieving a forming speed of 8-15 meters per minute. Its plate thickness compatibility spans the 0.3-0.8mm range, flexibly adapting to diverse order specifications. The core patented technology—automated stacking and conveying system—eliminates industry pain points of tile stacking collapse in traditional equipment through innovative partition plates and guide rod fixation structures, achieving over 30% production efficiency improvement. Energy-saving and eco-friendly design optimizes motor energy consumption, while automated waste collection devices reduce material waste and lower operational costs by 20%, aligning with green manufacturing trends.

Customer Value

Our products deliver stable and reliable performance, reducing rework rates and significantly enhancing market competitiveness. We provide lifetime technical support and rapid response services to ensure long-term efficient operation of equipment, creating sustainable value for customers and helping enterprises reduce costs and improve efficiency.

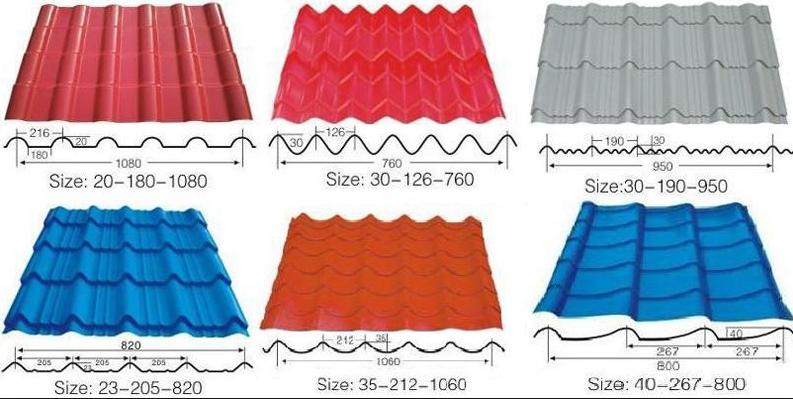

The profile drawing for the finished product:

Here are some profiles for your reference:

Application scenarios

This equipment is widely used in industrial plants, large sports venues, agricultural greenhouses, and commercial complex roofing projects. In heavy industry projects, it enables rapid production of large-area roof panels. In greenhouse construction, its high adaptability meets the requirements of curved roofs, ensuring efficient project delivery and providing reliable solutions for the construction industry.

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.