Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

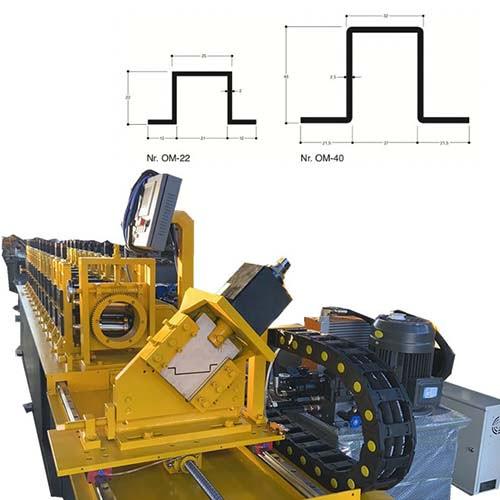

Galvanized Omega Steel Profile Rolling Forming Machine

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

Galvanized Omega Steel Profile Rolling Forming Machine

Steel Omega section matches to excellent plasticity and flexibility, high structural stability and more sensitive construction.he omega profile is used as a batten or self-supporting element for separating the facade and cladding. It is also used as a separator on roofs and ceilings. Other applications include the manufacture of greenhouses, metal shelves and metal furniture. Here are some drawing profiles for your reference:

Galvanized Omega Steel Profile Rolling Forming Machine:

For the Galvanized Omega Steel Profile Rolling Forming Machine parameters for your reference:

| Voltage | 380V ,50Hz, 3Phase (as customer request) |

| Frame type | Memorial arch frame |

| Drive mode | Chain as transmission |

| Material of rollers | GCr12mov |

| Material of shafts | 45# steel with tempering |

| Diameter of shafts | Φ70mm |

| Number of rollers | 15 rollers with dotting rollers |

| Main power | 7.5 kw |

| Raw Materials of the steel coil | Galvanized steel plate |

| Material thickness | 0.5-1.2 mm |

| Forming speed | 20 m per minute |

If you want to make a range of profiles by one machine we have two options for your reference:

Option A: Full;y automatic sizes adjustment like the following machine design, controlling sizes by PLC.

Option B: Manual adjustments for different sizes.

For the sizes 14x50x20, 20x50x55, 20x50x24, only need to adjust the first 5 roller station and change the cutting blade.

For the 20x120x35, you need to change the whole molds.

If you do not want to do the production in huge rate, better one sizes one machine.

Single profile, we can use the molding frame and servo tracking system to make sure the speed can reach 45 meter per minute. With the oiling system to make sure not peel off zine coating and not go heating when machine use for a long time.

If you want to enhance the working speed when you have punching, you can use online servo punching machine. Or use the CNC high speed punching machine.

Here is the receiving table for your reference:

For more information, you can contact us at any time.

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.