Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

EPS PU sandwich panel roll forming machine with high quality

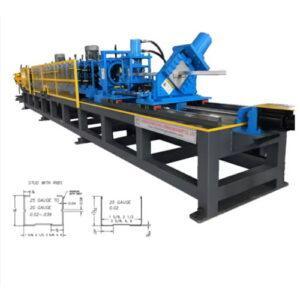

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

EPS PU sandwich panel roll forming machine with high quality including unwinding, before cutting, film, beading / molding, rock wool and spray delivery, Edge foam, continuous curing, cutting and other functions, high degree of automation, stable performance.Edge polyurethane foam systems, automatic feeding system, to ensure that the raw material requirements in full accordance with the ratio of mixing, spray evenly; using a reliable foam technology to ensure uniform sheet foam, dense, sheet closely connected.The production line is equipped with automaticcontrol system, userfriendly interface for easy operation, monitoring, advanced computer control, easy to adjust the entire line of argument, effectively ensure the production line stable and efficient operation.

EPS PU sandwich panel roll forming machine with high quality production Process:

(The upper)Dncoiler —Cutting —Film—Beading—Roll forming \

(Lower part)Uncoiler —Cutting →Film→Beading→Roll forming /

—Rock wool delivery—Glue—Sealing side foam— laminating machine with Foam,Solidify,Roll forming—

Cutting —Run-out table

Details of EPS PU sandwich panel roll forming machine with high quality :

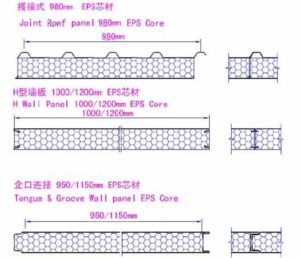

Panel showing :

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.