Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

Double Layer Roll Forming Machine(0-20m/min)

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

Double Layer Roll Forming Machine

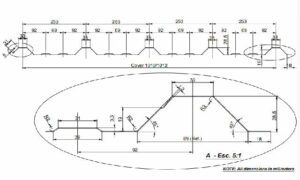

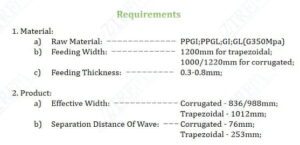

Double Layer Roll Forming Machine is designed to make the metal roofing sheet in the double layer forms, that means one machine can make two profiles by the rolling forming machine principle. In the following part, let us take the following drawing profile for example:

First IBR Layer:

Second layer:

Double Layer Roll Forming Machine we design like this:

- Description Of Goods:Double Layer Roll Forming Machine

Packing List:

Hydraulic Decoiler or manual decoiler ———- 1 set;

Main Roll Forming Machine ——- 1 set;

3M Simple Collecting Product Table — 1 set;

Hydraulic Station ————– 1 set;

PLC Control Cabinet ———— 1 set;

Double Layer Machine Production Line Layout And Process Flow:

| No. | Item | Specification |

| Whole Line | Working Speed | 0-20m/min |

| Total Power | 22kW; 380V-50Hz-3Phase | |

| Equipment Weight | 8.5 Tons | |

| Equipment Dimension | 8500mm*1850mm*1500mm | |

| Container | 1*40”GP | |

| Equipment Color | Blue Or Customizable | |

| Equipment Package | Nude Package | |

| Protective Cover | Optional |

For the hydraulic decoiler 7 ton, 8 ton or 10 Ton decoiler, we make it like the following pictures:

| No. | Item | Specification |

| Hydraulic Decoiler | Decoiling Type | Actively Uncoiling Type |

| Loading Capacity | 12 Tons | |

| Loading Width | Max. 1250mm | |

| Coil Inner Diameter | 450-550mm | |

| Coil Outer Diameter | Max. 1500mm | |

| Motor | 7.5kW+3kW |

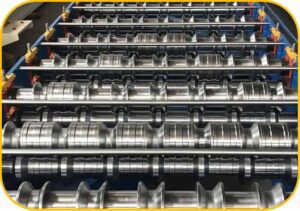

Double layer rolling forming machine Images And Specifications

| No. | Item | Specification |

| Main Roll Forming Machine | Main Forming Power | 7.5 kW; 380V-50Hz-3Phase |

| Speed | 0-20m/min | |

| Drive Type | 1” Single Chain | |

| Machine Architecture | Midde-plate Construction; 20mm Thick | |

| Roller Station | 18 Stations + 18 stations | |

| Roller Shaft | φ75mm Solid Shafts, with quenched | |

| Roller | 45# Steel HRC58-62°; Surface Hard Chromium Plating | |

| Bearing | Chinese Famous Brand Harbin | |

| Main Frame | 400# H-beam Steel Welded |

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.