Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

Double Layer Metal Roofing Sheet Rolling Forming Machine For Nicaragua

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

Double layer metal roofing sheet rolling forming machine for Nicaragua is specially designed rolling forming machine for Nicaragua market.

Double layer metal roofing sheet rolling forming machine for Nicaragua

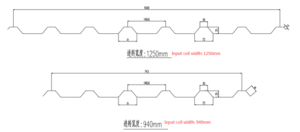

Double layer metal roofing sheet rolling forming machine for Nicaragua is specially designed rolling forming machine for Nicaragua market. Here are some drawing profile for your reference.

One double layer machine can make two type profiles. Upper layer is for IBR type and another layer is for round wave sheets. Both two profiles can support two input coil width 1250mm and 940mm. But then input coil width between this also could be used, for example 1000mm also could be used just the profile maybe not so good. Simple adjust the leveling beach then okay.

Double layer metal roofing sheet rolling forming machine for Nicaragua

How to adjust the input coil width for different input coil width:

At the leveling part, we will add the manual cutter by this way, you can cut the coil at any place.

The leveling roller we design use the stainless steel with the bearing inside of it and then it will not damage the surface of the coil.

Handrail for adjustment we give two, by this way you can adjust the input coil width center to center more easily.

Side roller can keep the coil going into the right direction.

As to the main rolling forming machine of double layer:

For all of our rollers, spacers and shafts, we all mark numbers on it, it’s very convenient for you to maintenance the machine in the future.

There is ball bearings inside the rollers, to make all the rollers run at same speed when machine is run. 3. Because the rollers inside with ball bearings, our rollers is bigger than others, so work speed is faster. 4. All rollers and spacers, we do 3mm thickness chrome coating, to increase hardness and anti-rust. Some factories maybe use 1-2mm chrome coating.

As to the shearing part, we design with two pole shearing by this way, it can work more steady.

About the quality control:

All the profiles we will test by ton of coil and measure sizes compared with the drawing profile, Meanwhile the overlap should be perfect.

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.