Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

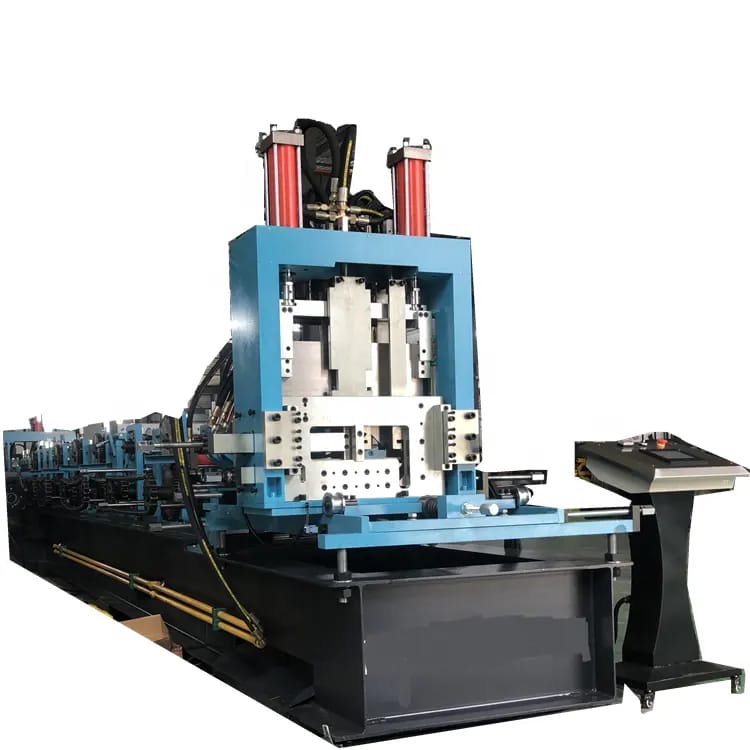

CZ Purlin Roll Forming Machine: Your Trusted Partner for High-Quality Steel Structure Production

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

In the fast-paced world of steel structure manufacturing, efficiency, precision, and reliability are the keys to staying ahead. Our CZ Purlin Roll Forming Machine is engineered to meet and exceed these demands, providing a one-stop solution for producing high-performance C-shaped and Z-shaped steel purlins—essential components for roofs, walls, and mezzanines in industrial plants, warehouses, commercial buildings, and residential projects.

High Efficiency: Boost Your Production Capacity

Time is money in manufacturing, and our CZ purlin roll forming machine is designed to maximize productivity.

Fast Forming Speed: With a forming speed of up to 15-25 meters per minute (adjustable based on material thickness), it significantly reduces production cycles compared to traditional manual or semi-automatic equipment.

Continuous Production: Equipped with an automatic material feeding system and coil decoiler, the machine enables non-stop operation, minimizing downtime and ensuring consistent output even for large-volume orders.

Dual-Function Design: One machine can produce both C-shaped and Z-shaped purlins by simply adjusting the mold—no need to invest in separate equipment, saving your workshop space and capital costs.

Precision Craftsmanship: Ensure Consistent Quality

Steel purlins require strict dimensional accuracy to fit perfectly in steel structures. Our machine guarantees exceptional precision through advanced technology:

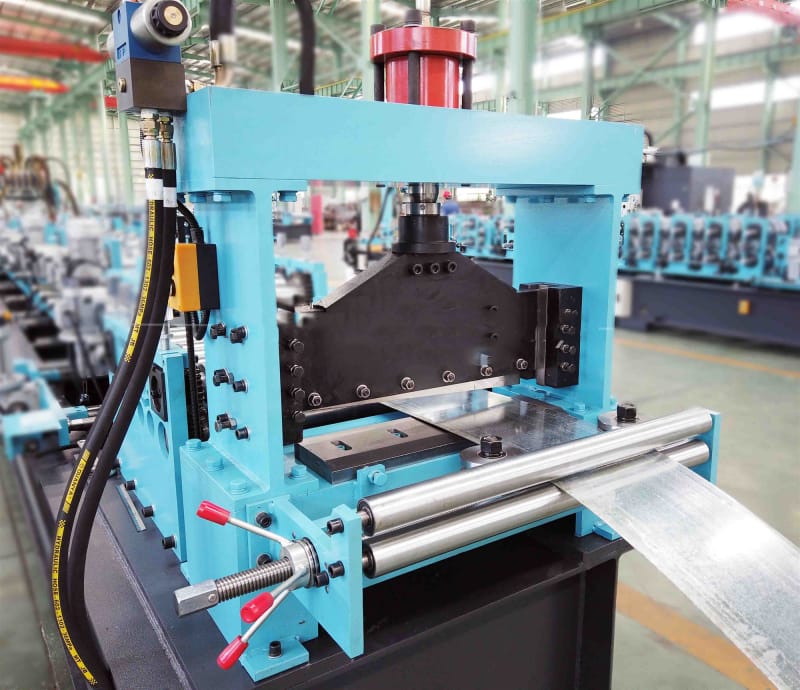

High-Precision Roll Forming Stands: Made of high-quality alloy steel, the forming stands undergo strict heat treatment and grinding, ensuring stable forming and reducing material deformation. The dimensional tolerance of finished purlins is controlled within ±0.5mm, meeting international standards (e.g., AISI, DIN, GB).

Automatic Cutting System: Equipped with a hydraulic or servo-driven cutting device, the machine cuts purlins to custom lengths (from 1m to 12m) with smooth edges and no burrs—no secondary processing required.

Digital Control Panel: The user-friendly PLC touchscreen allows operators to set parameters (length, quantity, speed) easily. It also has a memory function to store common production recipes, improving operational efficiency.

Flexible Adaptability: Meet Diverse Needs

Every project has unique requirements, and our CZ purlin roll forming machine is highly flexible to adapt to different scenarios:

Wide Material Compatibility: It can process hot-rolled steel coils, cold-rolled steel coils, and galvanized steel coils with thicknesses ranging from 1.5mm to 4.0mm—suitable for various environmental conditions (e.g., humid, corrosive areas).

Customizable Purlins: From standard sizes (C100-C300, Z100-Z300) to non-standard dimensions, we can customize the forming molds according to your specific drawings. This ensures that the purlins fit perfectly with your steel structure designs.

Easy Installation & Maintenance: The machine is modularly designed, making on-site installation and debugging quick (usually 3-5 days). Key components (e.g., bearings, motors) are from well-known international brands (Siemens, SKF), ensuring durability and easy access to replacement parts globally.

Why Choose Our CZ Purlin Roll Forming Machine?

Cost-Effective: High efficiency reduces labor costs; dual-function design saves equipment investment.

Quality-Guaranteed: Precision forming meets international standards; durable components ensure long service life.

Customer-Centric: Customizable solutions and global after-sales support adapt to your needs.

Whether you are a small steel fabricator or a large construction company, our CZ Purlin Roll Forming Machine will be your reliable partner to enhance production efficiency and expand business opportunities. Contact us today for a customized quote and detailed technical specifications!

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.