Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

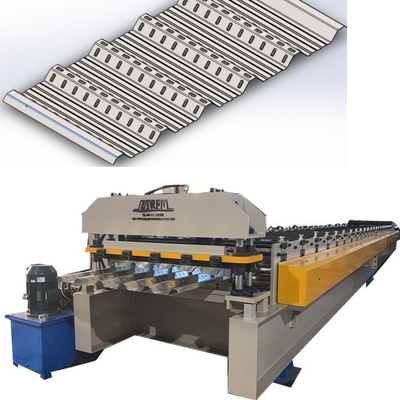

Composite Metal Floor Deck Roll Forming Machine:The Ideal Solution for Modern Construction

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

In the dynamic landscape of modern construction, the Composite Metal Floor Deck Roll Forming Machine has emerged as an indispensable asset. As the construction industry continues to evolve, demanding innovative and efficient solutions, this machine stands at the forefront, revolutionizing the production of composite metal floor decks.

Composite metal floor decks play a pivotal role in modern building projects. They provide a robust and reliable structural foundation for floors in various types of buildings, from towering skyscrapers to expansive industrial facilities. Their lightweight yet high – strength nature, combined with excellent fire – resistance and durability, makes them a preferred choice among architects, engineers, and contractors worldwide.

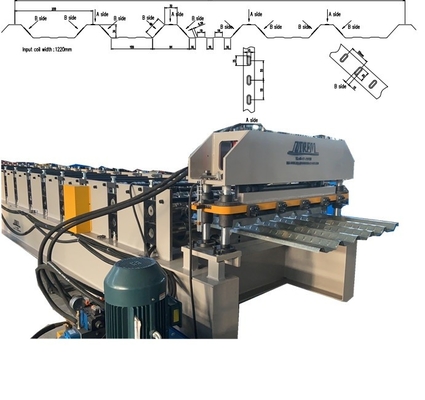

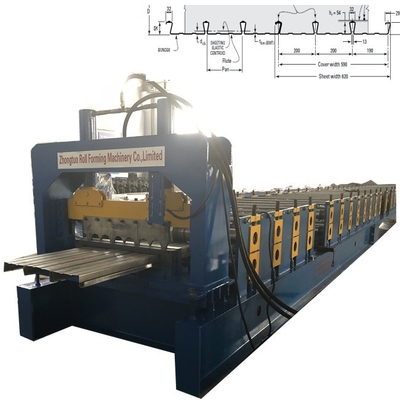

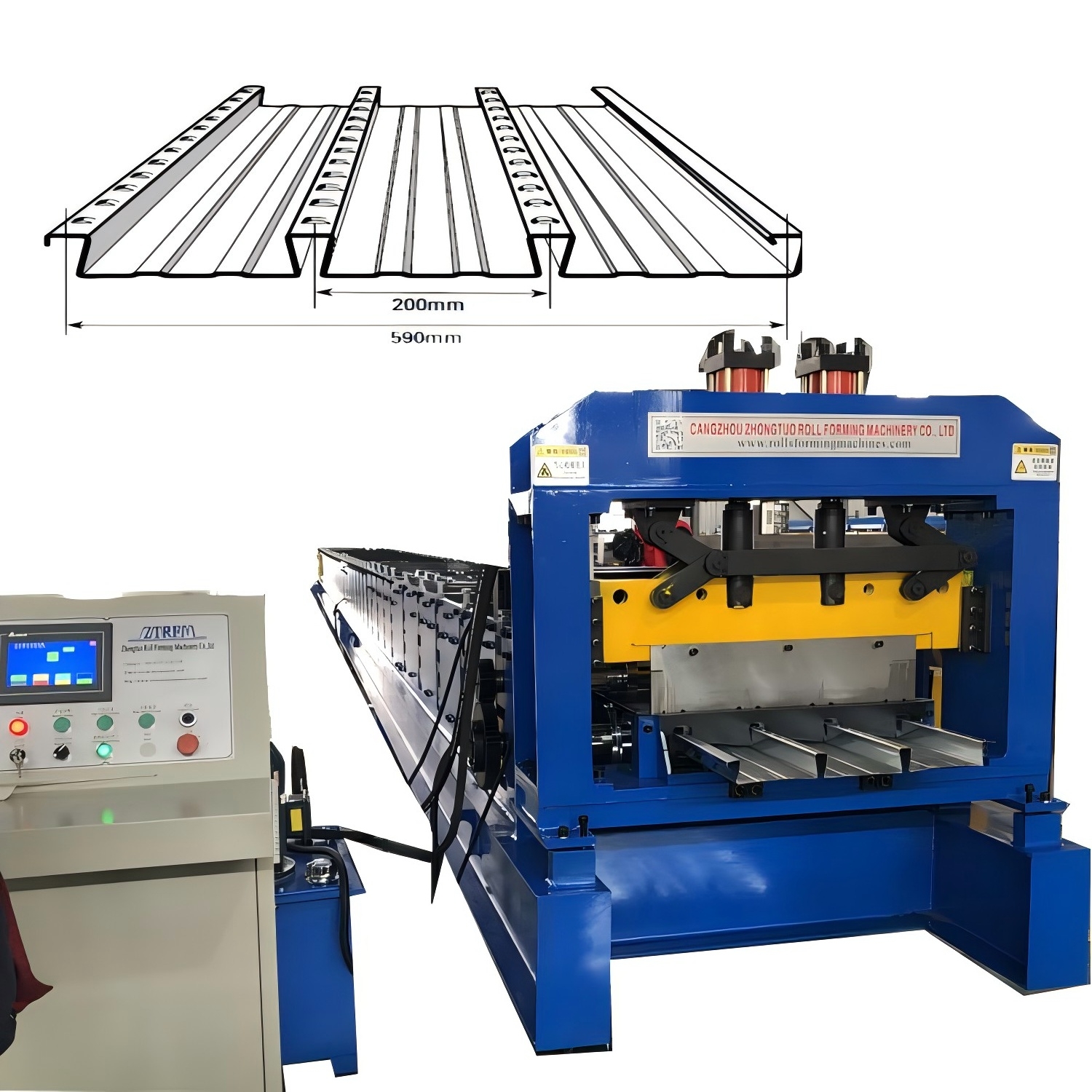

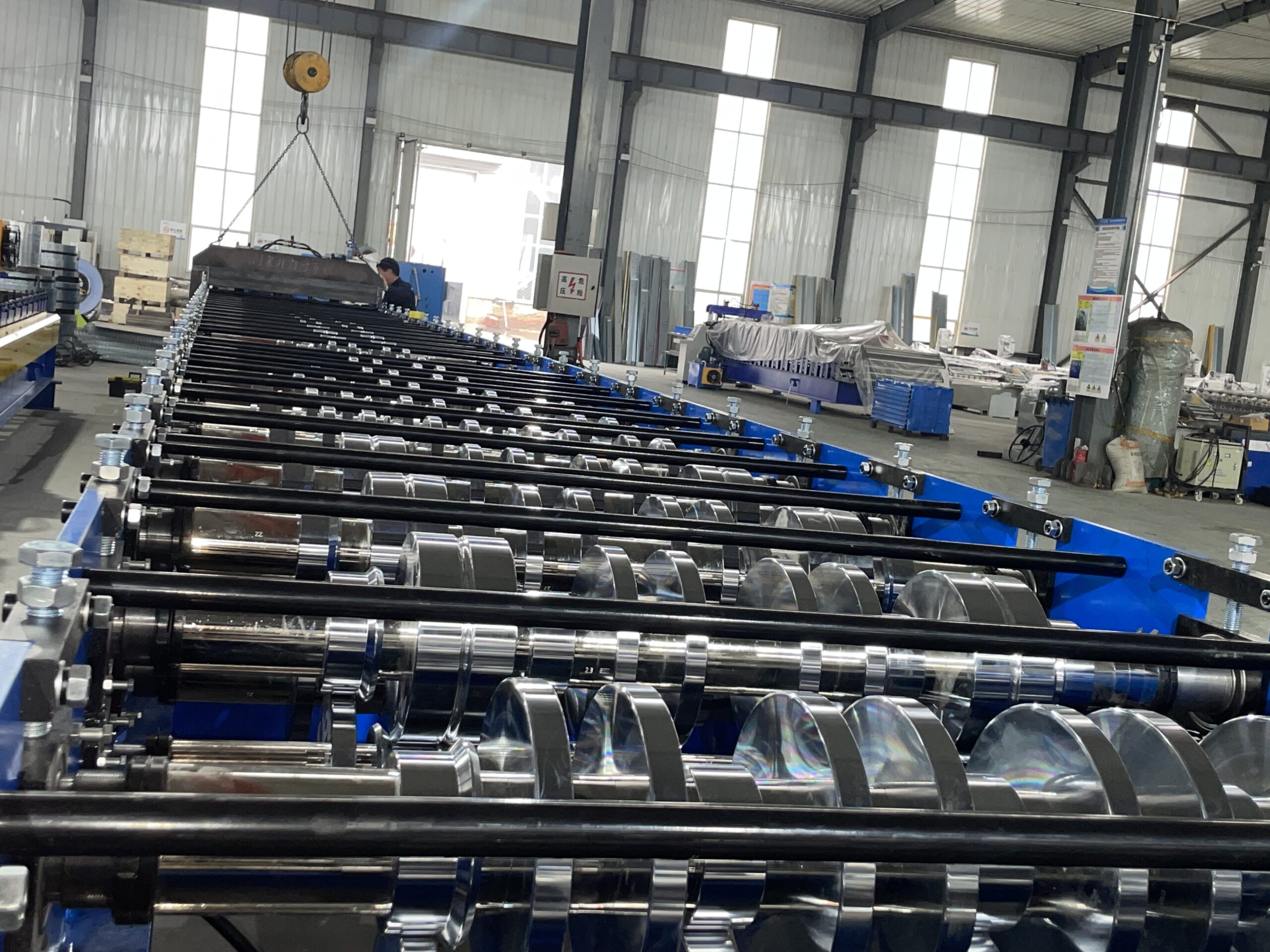

The roll forming machine is the key to producing these high – quality composite metal floor decks. It takes raw metal coils and, through a series of precision – engineered rollers and forming processes, transforms them into the intricately shaped and dimensionally accurate floor deck profiles required by the construction industry. This not only ensures the consistent quality of the end – product but also significantly enhances production efficiency, reducing both time and labor costs.

High – Precision Roll Forming

Our Composite Metal Floor Deck Roll Forming Machine is equipped with state – of – the – art high – precision roll forming technology. The rollers are crafted with meticulous attention to detail, ensuring that each composite metal floor deck produced has exact dimensions. Whether it’s the width, depth, or the intricate profile of the deck, the tolerance levels are kept to a minimum. This results in floor decks that fit together seamlessly during construction, reducing the need for on – site adjustments. For high – rise buildings where structural integrity and dimensional accuracy are of utmost importance, our machine’s high – precision output meets and exceeds the most stringent international construction standards. It guarantees a consistent quality of floor decks, providing a reliable base for the entire building structure.

Robust Construction

Built to last, the machine features a robust construction. We use only the highest – quality materials in its manufacturing. The main frame is constructed from heavy – duty steel, which can withstand the high – pressure forces exerted during the roll forming process. The components, such as the shafts, bearings, and gears, are sourced from renowned suppliers known for their durability. This not only ensures the long – term stable operation of the machine but also significantly reduces the frequency of maintenance. With less downtime for repairs, your production can run smoothly, maximizing productivity and minimizing production disruptions. In the long run, the reduced maintenance costs contribute to a lower total cost of ownership for your business.

Customizable Production

We understand that every construction project is unique, and that’s why our roll forming machine offers customizable production options. Whether you need floor decks with specific rib heights, different sheet thicknesses, or unique cross – sectional shapes, our machine can be adjusted to meet your requirements. Our experienced engineering team works closely with clients to understand their project needs and then modifies the machine settings and tooling accordingly. This flexibility allows us to serve a wide range of construction applications, from standard commercial buildings to specialized industrial facilities with unique design specifications.

High – Efficiency Production Speed

Time is money in the construction industry, and our Composite Metal Floor Deck Roll Forming Machine is designed to save both. It operates at a high – efficiency production speed, capable of processing large volumes of metal coils in a short period. The automated feeding and roll forming processes are optimized to minimize the time between each cycle, allowing for a continuous and rapid production flow. For large – scale construction projects, this high – speed production can significantly shorten the project’s overall duration. By getting the floor decks produced and delivered faster, construction teams can move on to subsequent construction phases earlier, ultimately accelerating the completion of the entire building project and improving overall production efficiency.

Wide Application Scenarios

1.Commercial Buildings

In commercial buildings such as shopping malls and office buildings, the Composite Metal Floor Deck Roll Forming Machine – produced floor decks are widely used. In large – scale shopping malls, these floor decks need to support heavy loads from large – scale commercial equipment, display racks, and a large number of pedestrians. The high – strength and load – bearing capacity of the composite metal floor decks produced by our machine meet these requirements perfectly. For example, in a newly built large – scale shopping center, the multi – story structure requires a floor system that can ensure long – term stability and safety. Our composite metal floor decks, with their excellent structural integrity, provide a reliable foundation.

In office buildings, especially high – rise office towers, the need for a lightweight yet strong floor system is crucial. The lightweight nature of the composite metal floor decks helps to reduce the overall weight of the building, which is beneficial for the building’s foundation and structural design. At the same time, their fire – resistance properties add an extra layer of safety, protecting the building and its occupants in case of a fire. Moreover, the smooth and flat surface of the floor decks can be easily finished with various floor coverings, such as carpets or wooden floors, meeting the aesthetic and functional needs of modern office spaces.

2.Residential Buildings

For residential buildings, our composite metal floor decks offer a host of advantages. In multi – story apartment buildings, the floors need to meet strict sound – insulation and vibration – reduction requirements. The composite structure of the floor decks, with its combination of metal and other materials, helps to absorb and reduce sound and vibrations, providing a more comfortable living environment for residents.

In addition, in modern residential construction, speed of construction is also a key factor. The high – efficiency production of our roll forming machine allows for a quick supply of floor decks, which can significantly shorten the construction period of residential projects. This not only reduces construction costs but also enables developers to deliver the housing units to the market faster. What’s more, the durability of the composite metal floor decks means that they can withstand the wear and tear of daily life in residential buildings, ensuring a long – lasting and reliable floor system for homeowners.

3.Industrial Facilities

Industrial facilities, such as factories and warehouses, have unique requirements for floor structures, and our composite metal floor decks are well – suited to meet them. In industrial plants, heavy machinery and equipment are often in use, which requires a floor that can bear extremely high loads. The high – strength composite metal floor decks produced by our roll forming machine can easily handle these heavy – duty applications. For example, in an automotive manufacturing plant, where large – scale stamping machines and conveyor systems are in operation, the floor decks need to be able to support the weight and vibrations of these machines without deformation.

Warehouses also benefit from the use of composite metal floor decks. Their smooth surface allows for easy movement of forklifts and other material – handling equipment, improving the efficiency of warehouse operations. Additionally, the corrosion – resistance of the metal components in the floor decks is especially important in industrial environments where they may be exposed to various chemicals and moisture. This ensures the long – term performance and structural integrity of the floors in industrial facilities, reducing the need for frequent floor replacements and maintenance.

Professional R & D Team

Our company takes pride in its professional R & D team, which is the driving force behind the continuous innovation and improvement of our Composite Metal Floor Deck Roll Forming Machine. Comprising experienced mechanical engineers, electrical engineers, and materials experts, this team stays at the forefront of industry trends and technologies.

They are constantly exploring new ways to enhance the machine’s performance, from optimizing the roll forming process to improving the control system. For instance, they recently developed a new roller design that reduces friction during the forming process, resulting in less wear and tear on the machine and an even higher – quality finish on the floor decks. The R & D team also conducts regular research on new materials and manufacturing techniques, enabling us to offer our customers the most advanced and efficient solutions in the market. They work closely with our production and sales teams, ensuring that the products we develop meet both the technical requirements of the industry and the specific needs of our clients.

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.