Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

Automatic Multi-size C-channels & Box Channels Rolling Forming Machine

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

Automatic Multi-size C-channels & Box Channels Rolling Forming Machine

Automatic multi-size C-Channels & Box Channels rolling forming machine is designed to make the many sizes C profiles by one machine.

Automatic multi-size C-Channels & Box Channels rolling forming machine

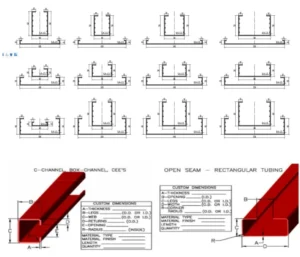

Automatic multi-size C-Channels & Box Channels rolling forming machine is designed to make the many sizes C profiles by one machine. C Channel & Box Channel thicknesses vary from .003″ thick up to .150″ thick. On 1/4 & 1/2 hard aluminum, Aluminum C Channel & Aluminum Box Channel thicknesses can reach up to .250″ thick. Many different decorative pre-coated metals are generally not recommended when more than .030″ thickness is required unless larger than normal corner radii can be used. Some coatings can be used, however, up to .125″ thick such as a pre-finished Hot Dip Galvanized coating. Box Channel & C-Channel Lengths may be from 3″ thru 40 feet long with close tolerances. Many different lengths can be put on one purchase order. Here are some sizes for your reference:

C Channels & Box Channels have many popular uses.

C Channels, Box Channels, Open Seam: Square and Rectangular Tubing are used in almost all industries for any possible application such as in this brief summary of other known terms:By this they can use two C channel instead of on metal tube.

Automatic multi-size C-Channels & Box Channels rolling forming machine

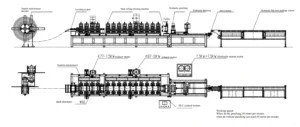

Machine working flow for your reference:

More details of the Automatic multi-size C-Channels & Box Channels rolling forming machine:

Advantages of Automatic multi-size C-Channels & Box Channels rolling forming machine:

Pressure roller material: Stainless steel and then it will not damage the coil and never go rusting.

Split rollers to realize one machine to produce C drywall products with different bottom widths.

Fully automatic PLC control.

It supports both manual adjustment and PLC adjusting for different sizes.

High speed to 50 meter per minute.

It supports online punching

Logo adding and others.

Purlin machine video channel

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.