기술 변화 및 산업 시스템, 우리는 다음과 같이 헌신합니다.

소중한 고객에게 최고의 경제적인 솔루션을 제공합니다.

Standing Seam Roll Forming Machine: Precision & Efficiency Redefined

다양한 유형의 냉간 압연 성형기. 우리는 2006 년부터 롤 성형 기계의 설계 및 제조에 종사하는 오랜 역사를 가진 공장입니다. 우리가 생산할 수있는 기계에는 지붕 타일 제조 기계, cz 도리 제조 기계, 경강 용골 제조 기계, 금속 엠보싱 기계, 도어 시스템 성형 기계, 천장 시스템 성형 기계, 고주파 파이프 용접기, 슬리 팅 라인, 절단 길이 라인, 선반 시스템 성형 기계, 바닥 데크 성형 기계, 컬러 석재 타일 생산 라인, 핫 라미네이팅 필름 기계 등이 있습니다.

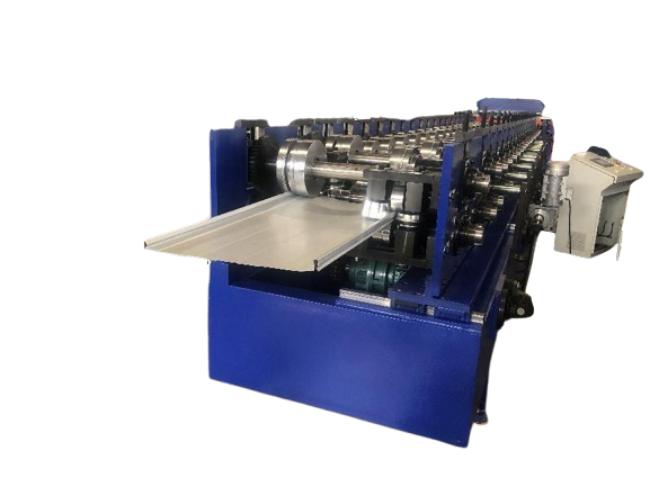

As a leading supplier of metal forming equipment, we take pride in presenting our Standing Seam Roll Forming Machine—a game-changer for your roofing and cladding projects. Engineered with global standards in mind, this machine combines robust performance, exceptional precision, and user-friendly operation to elevate your production line and boost market competitiveness.

Unmatched Advantages for Your Production

Our standing seam roll forming machine is designed to address the core demands of metal processing industries, with advantages that stand out in the global market:

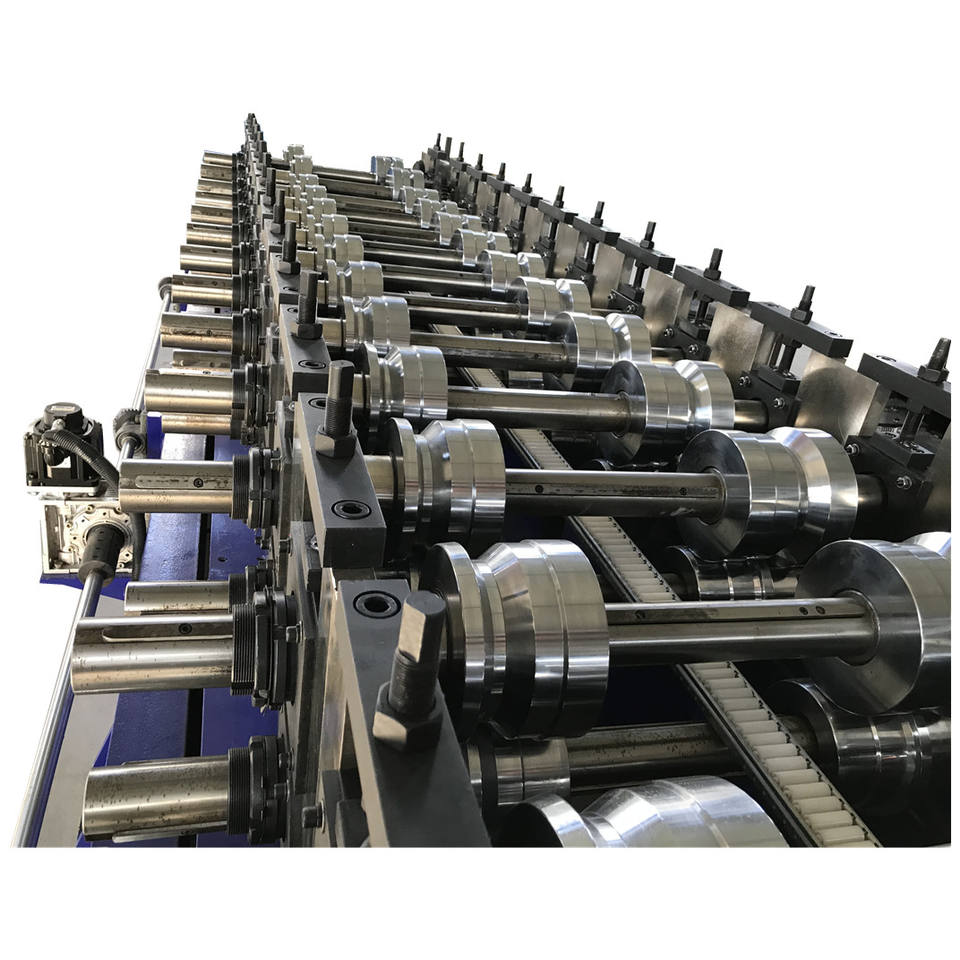

1.Superior Forming Precision, Consistent Quality

Equipped with high-hardness alloy rollers (HRC 58-62) and a precision-guided transmission system, the machine ensures uniform seam height, tight locking, and smooth surface finish for every metal sheet. The error margin of seam dimensions is controlled within ±0.1mm, perfectly meeting the strict standards of architectural and industrial roofing applications. No more rework—just reliable, consistent products batch after batch.

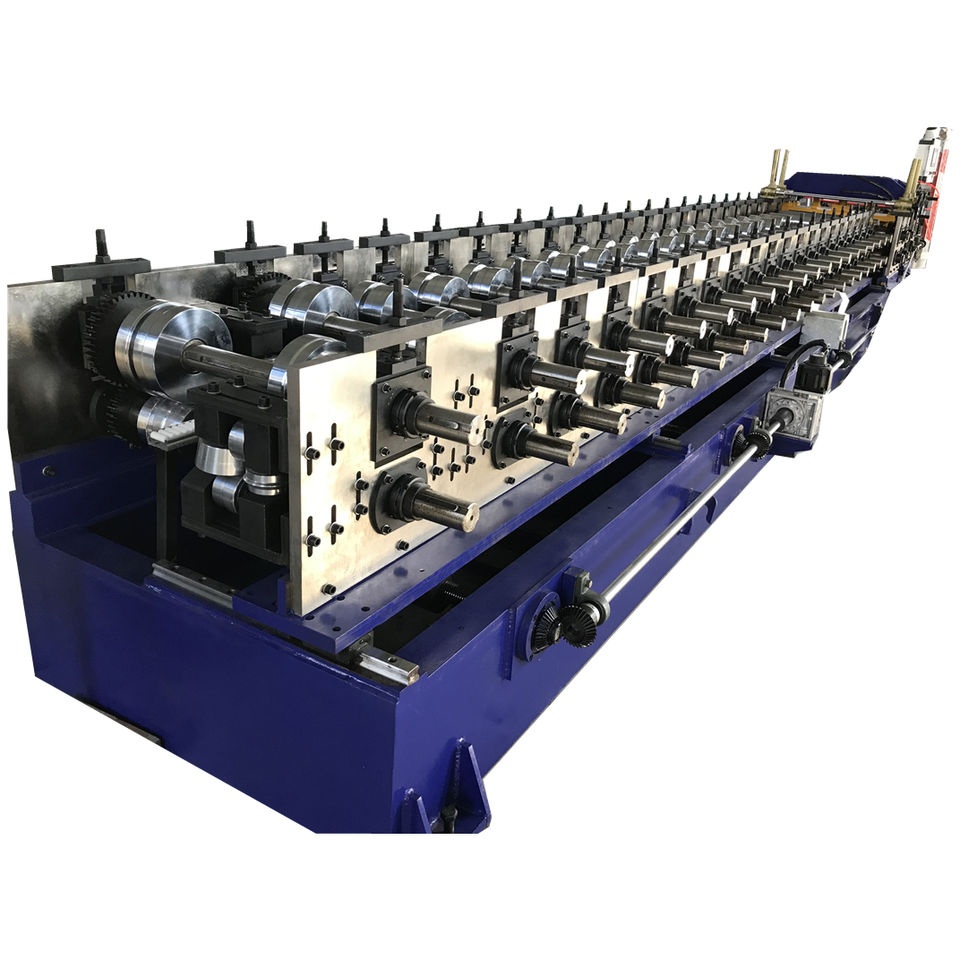

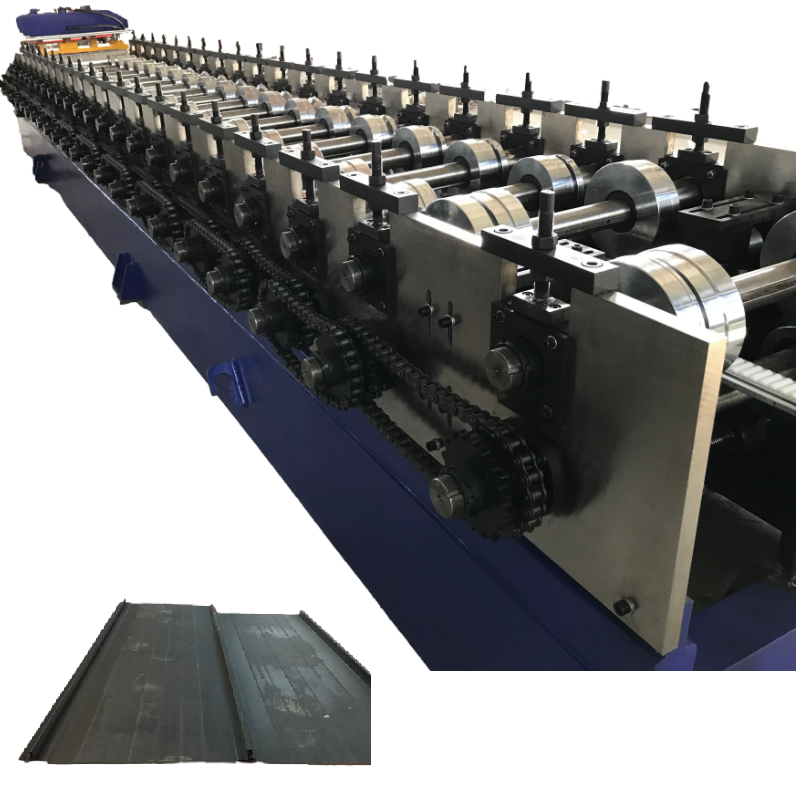

2.High-Speed Production, Maximized Output

With a maximum forming speed of 15-20m/min (adjustable according to material thickness), the machine significantly outperforms traditional equipment. It supports continuous feeding and automatic cutting, minimizing downtime between processes. Whether processing aluminum, galvanized steel, or color-coated steel (0.3-1.2mm thickness), it maintains stable performance, helping you fulfill large orders efficiently and meet tight delivery deadlines.

3.Flexible Customization, Wide Application

We understand that different markets have diverse requirements. Our machine offers flexible adjustment of seam types (such as snap-lock, mechanical lock) and sheet widths (300-600mm customizable). It is ideal for manufacturing standing seam roofing panels, wall cladding, and decorative metal sheets used in commercial buildings, industrial warehouses, villas, and agricultural facilities—adapting to your specific project needs with ease.

4.Durable Structure, Low Maintenance Cost

The main frame is made of heavy-duty steel with integral welding and tempering treatment, ensuring strong load-bearing capacity and resistance to deformation. Key components are sourced from international brands, reducing failure rates. The machine features a modular design, making routine maintenance and part replacement simple—lowering your long-term operation costs.

5.Intelligent Operation, Easy to Master

Equipped with a touch-screen control system, the machine allows one-click setting of parameters (length, quantity, speed) and real-time monitoring of production status. It has built-in fault alarm functions (such as material shortage, overload) to avoid production accidents. Even new operators can master the operation within a short training period, reducing labor costs.

스탠딩 심 머신 비디오 채널

왜 우리를 선택해야 할까요?

OEM/ODM 및 커스터마이징 원스톱 서비스

완벽한 애프터 서비스 지원

OEM, ODM 제공

2.기술자 설계: 도면 프로파일 및 3D 기계 도면 만들기

3.구성 및 프로덕션 결정

4.배송 전 테스트

6.기술 가이드

7.판매 후 서비스: 복잡한 기계의 설치 서비스 및 정기 고객 방문 서비스

95800개 이상의 기업이 신뢰하는 기업

고품질 기업. 당사와의 협력을 통해 다음과 같은 혜택을 받았습니다.

강력한 지원과 비즈니스 혁신 및 발전을 이루었습니다.