기술 변화 및 산업 시스템, 우리는 다음과 같이 헌신합니다.

소중한 고객에게 최고의 경제적인 솔루션을 제공합니다.

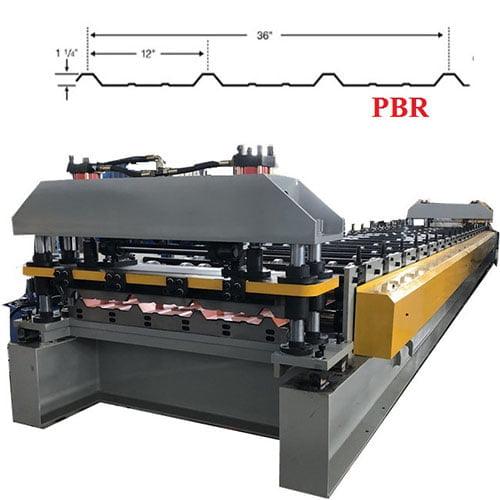

PBR panel, Max rib panel , Ag panel metal roofing sheet rolling forming machine

다양한 유형의 냉간 압연 성형기. 우리는 2006 년부터 롤 성형 기계의 설계 및 제조에 종사하는 오랜 역사를 가진 공장입니다. 우리가 생산할 수있는 기계에는 지붕 타일 제조 기계, cz 도리 제조 기계, 경강 용골 제조 기계, 금속 엠보싱 기계, 도어 시스템 성형 기계, 천장 시스템 성형 기계, 고주파 파이프 용접기, 슬리 팅 라인, 절단 길이 라인, 선반 시스템 성형 기계, 바닥 데크 성형 기계, 컬러 석재 타일 생산 라인, 핫 라미네이팅 필름 기계 등이 있습니다.

PBR panel, Max rib panel , Ag panel metal roofing sheet rolling forming machine

PBR panel, Max rib panel , Ag panel metal roofing sheet rolling forming machine is designed to make the metal roofing sheets in batch fully automatically. PBR panel, Max rib panel , Ag panel metal roofing sheet are quite popular in USA and South American. Here we will take those drawing profile for example to show you how our metal roofing sheet machine is designed.

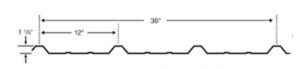

R-Panel roofing sheet

R-Panel is a multi-use wall and roof panel used primarily in pre-engineered metal building applications. R-Panel is also a popular choice for residential metal roofing, especially in the Southwest. An optional purlin bearing leg (PBR] rests on purlins and provides support for fastening the panel lap

.

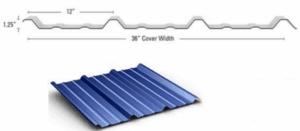

Max- Rib Panel roofing sheet

Max: Rib is a low profile (3/4″) panel that is equally well suited for residential roofing and post frame applications.

Varying applications, end uses, and expectations require different metal panel alternatives. Fortunately, Zhongtuo

popular Max-Rib profile is available in five distinct options: Max-Rib UItra, Max Rib I, Max-Rib 100, and Max-Rib

Commodity/Liner. The best choice for your individual project depends on factors such as performance, desired

longevity, and budget.

The PBR metal roof profile:

The PBR metal roof and wall panel is a high-quality, versatile option. They can be easily installed both horizontally and vertically, ensuring a functional design that meets the requirements of your customers’ building projects.

PBR panel, Max rib panel , Ag panel metal roofing sheet rolling forming machine:

| Machine frame | 350mm H beam structure, with 20mm welded steel middle support plate. |

| Material of rollers

| High grade 45# forged steel |

| Chromed treatment (Chrome thickness:0.05 mm), make the rollers surface more smoothly, improve the hardness and prevent abrasion, anti corrosion increase of service life | |

| Forming stations

| Upper layer 18 roller station |

| Rolling type: separate rolling design concept, it can release internal stress from the sheets, then the sheet will be in good shape and high precision. | |

| Diameter of shafts | Φ80mm solid |

| Material of shafts | High grade 45#,with heat treatment |

| Forming speed | 0-25m/min |

| voltage | 380V/50HZ/3P (as requested) |

| Transmission way | By 1 inch chain |

| Main motor | 7.5KW |

| Cutting blade material | Gcr12 quenched treatment |

| Cutting type | hydraulic post cutting |

| Driving method | By pillar type Cylinder |

And if you like to add the cut to length function, we can also add for you. The cut to length could be together with the PLC and help you cut the coil to pieces and then use for ridge cap or gutters bending profile.

Machine base frame

1.There are diagonal brace in the machine base frame,which can make the machine frame more stable and stronger.

2.After the whole welding, vibration is used to weld the stress. After large-scale planer machining, the horizontal and rigidity of the frame are ensured.

3.Hand wheels on both sides can be used to adjust the feeding width.

4.Four stainless rollers can make the material go into the machine smoothly and prevent the scratch on the material surface.

5.There are three rows of orange plastic rollers can make the steel coil go into the machine smoothly.

As to the decoiler and stacker, you can choose the manual one or hydraulic one according to your requirements

| Machine frame | 350mm H beam structure, with 20mm welded steel middle support plate. |

| Material of rollers

| High grade 45# forged steel |

| Chromed treatment (Chrome thickness:0.05 mm), make the rollers surface more smoothly, improve the hardness and prevent abrasion, anti corrosion increase of service life | |

| Forming stations

| Upper layer 18 roller station |

| Rolling type: separate rolling design concept, it can release internal stress from the sheets, then the sheet will be in good shape and high precision. | |

| Diameter of shafts | Φ80mm solid |

| Material of shafts | High grade 45#,with heat treatment |

| Forming speed | 0-25m/min |

| voltage | 380V/50HZ/3P (as requested) |

| Transmission way | By 1 inch chain |

| Main motor | 7.5KW |

| Cutting blade material | Gcr12 quenched treatment |

| Cutting type | hydraulic post cutting |

| Driving method | By pillar type Cylinder |

왜 우리를 선택해야 할까요?

OEM/ODM 및 커스터마이징 원스톱 서비스

완벽한 애프터 서비스 지원

OEM, ODM 제공

2.기술자 설계: 도면 프로파일 및 3D 기계 도면 만들기

3.구성 및 프로덕션 결정

4.배송 전 테스트

6.기술 가이드

7.판매 후 서비스: 복잡한 기계의 설치 서비스 및 정기 고객 방문 서비스

95800개 이상의 기업이 신뢰하는 기업

고품질 기업. 당사와의 협력을 통해 다음과 같은 혜택을 받았습니다.

강력한 지원과 비즈니스 혁신 및 발전을 이루었습니다.