기술 변화 및 산업 시스템, 우리는 다음과 같이 헌신합니다.

소중한 고객에게 최고의 경제적인 솔루션을 제공합니다.

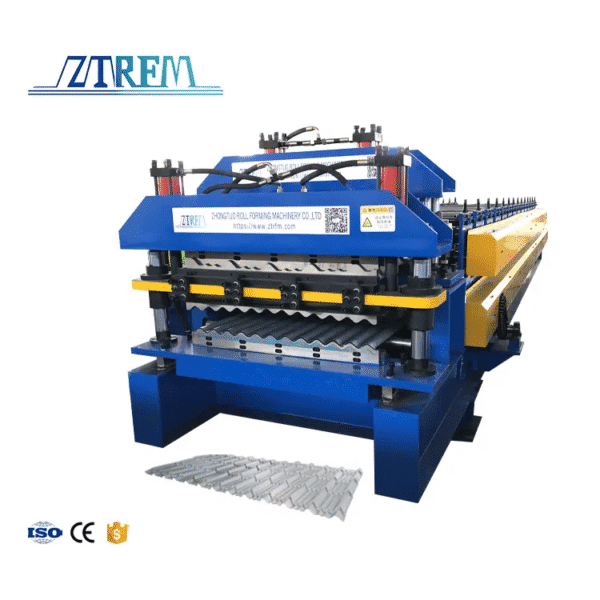

Automatic Double-layer Steel Roof Panel Roll Pressing Machine

다양한 유형의 냉간 압연 성형기. 우리는 2006 년부터 롤 성형 기계의 설계 및 제조에 종사하는 오랜 역사를 가진 공장입니다. 우리가 생산할 수있는 기계에는 지붕 타일 제조 기계, cz 도리 제조 기계, 경강 용골 제조 기계, 금속 엠보싱 기계, 도어 시스템 성형 기계, 천장 시스템 성형 기계, 고주파 파이프 용접기, 슬리 팅 라인, 절단 길이 라인, 선반 시스템 성형 기계, 바닥 데크 성형 기계, 컬러 석재 타일 생산 라인, 핫 라미네이팅 필름 기계 등이 있습니다.

The innovative design of the double-layer steel roof sheet roll forming machine has revolutionized the limitations of traditional single-line production, making it the preferred equipment for industrial plants, warehousing and logistics centers, and residential buildings.

Precision Control System of Double Layer Molding

Our forming machine employs the core technology of ‘zoned drive + intelligent calibration’ to digitally control the entire process of converting steel strips into high-precision double-layer roof panels, ensuring both upper and lower layers meet international standards.

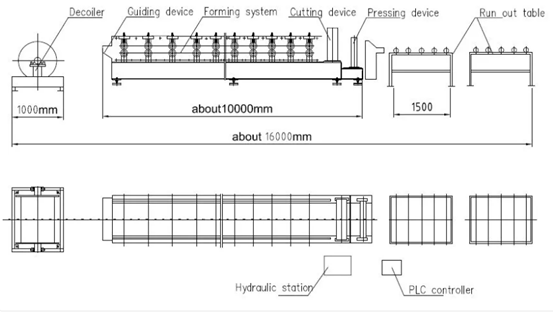

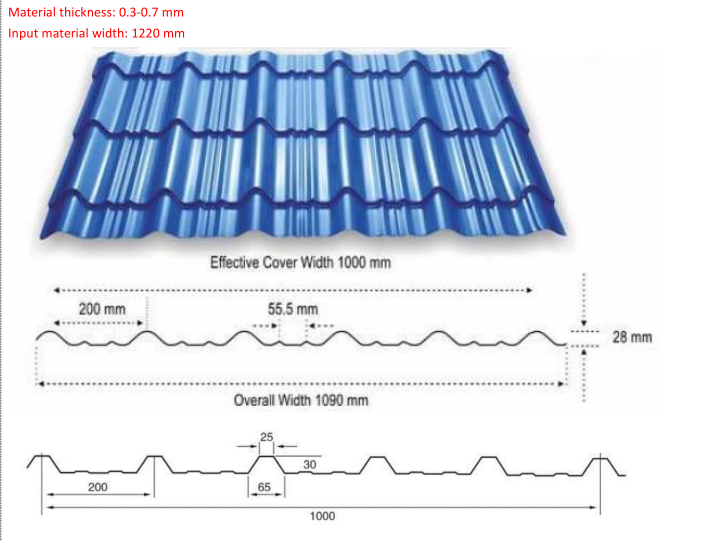

The raw material processing stage establishes dual safeguards: A 5-ton hydraulic uncoiler paired with a four-stage leveling system enables stable handling of various substrates, including color-coated steel plates, galvanized steel plates, and aluminum alloy plates, with widths ranging from 800 to 1220mm and thicknesses from 0.5 to 0.18-1.0mm. Through hydraulic tension control and laser alignment, feed deviations are maintained within ±0.05mm. The core forming stage employs a ‘dual independent roll system,’ featuring 24 corrugated plate forming rolls on the upper layer and 18 glazed tile forming rolls on the lower layer. These rolls are coated with hard chrome on 45# steel, achieving a surface roughness of Ra0.8μm to ensure scratch-free and pressure-free sheet formation.

Quality upgrade

The double-layer roof panels manufactured by our equipment achieve dual breakthroughs in mechanical performance and waterproofing. Third-party tests confirm that the corrugated panels exhibit a bending strength of 280MPa, while the glazed tiles demonstrate a flexural strength of 150MPa—both surpassing international standards by 30%. The proprietary edge-biting molding process enhances inter-panel overlap sealing by 80%, and when paired with specialized sealing strips, it achieves a water resistance of 0.3MPa, effectively resolving leakage issues common in traditional roof panels. In a Thai industrial park project, the panels produced by our equipment have been in stable service for 12 years, remaining rust-free and deformation-free despite exposure to tropical storms and intense UV radiation.

Full-scenario adaptation: from tropical typhoon zone to cold zone

To address diverse global climate and architectural requirements, our forming facility has developed a “multi-pattern, multi-material, and customized” adaptation system. The system covers 12 mainstream roofing panel types, including 840/850/900 corrugated sheets, glazed tiles, and antique-style tiles. Production can be achieved by combining any two panel types through rapid roller group replacement (type change ≤45 minutes). Material compatibility spans from standard color-coated steel sheets to 550MPa high-strength galvanized sheets, and from aluminum alloy plates to corrosion-resistant weathering steel, all achieving perfect forming through intelligent parameter adjustments.

왜 우리를 선택해야 할까요?

OEM/ODM 및 커스터마이징 원스톱 서비스

완벽한 애프터 서비스 지원

OEM, ODM 제공

2.기술자 설계: 도면 프로파일 및 3D 기계 도면 만들기

3.구성 및 프로덕션 결정

4.배송 전 테스트

6.기술 가이드

7.판매 후 서비스: 복잡한 기계의 설치 서비스 및 정기 고객 방문 서비스

95800개 이상의 기업이 신뢰하는 기업

고품질 기업. 당사와의 협력을 통해 다음과 같은 혜택을 받았습니다.

강력한 지원과 비즈니스 혁신 및 발전을 이루었습니다.