技術的変化と産業システム、私たちの使命

セッズは、お客様にとって最善かつ経済的なソリューションを提供します。

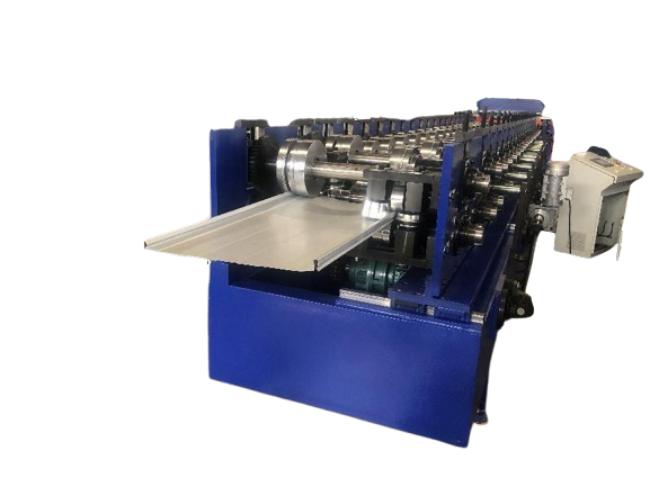

Standing Seam Roll Forming Machine: Precision & Efficiency Redefined

冷間ロール成形機の異なるタイプ。私達は 2006 年以来の機械を形作るロールの設計そして製造で従事している長い歴史の工場です。私達が作り出してもいい機械は下記のものを含んでいます: 機械、機械を作る cz の母屋を作る屋根瓦機械、機械を作る軽い鋼鉄キール、金属浮彫りになる機械、機械を形作るドア システム天井システム高周波管の溶接機、ラインを切り開くこと、長さライン、機械を形作る棚システムを形作る床 Decking 機械、色の石造りのタイルの生産ライン、熱い薄板になるフィルムで形造る機械、等を切ります。

As a leading supplier of metal forming equipment, we take pride in presenting our Standing Seam Roll Forming Machine—a game-changer for your roofing and cladding projects. Engineered with global standards in mind, this machine combines robust performance, exceptional precision, and user-friendly operation to elevate your production line and boost market competitiveness.

Unmatched Advantages for Your Production

Our standing seam roll forming machine is designed to address the core demands of metal processing industries, with advantages that stand out in the global market:

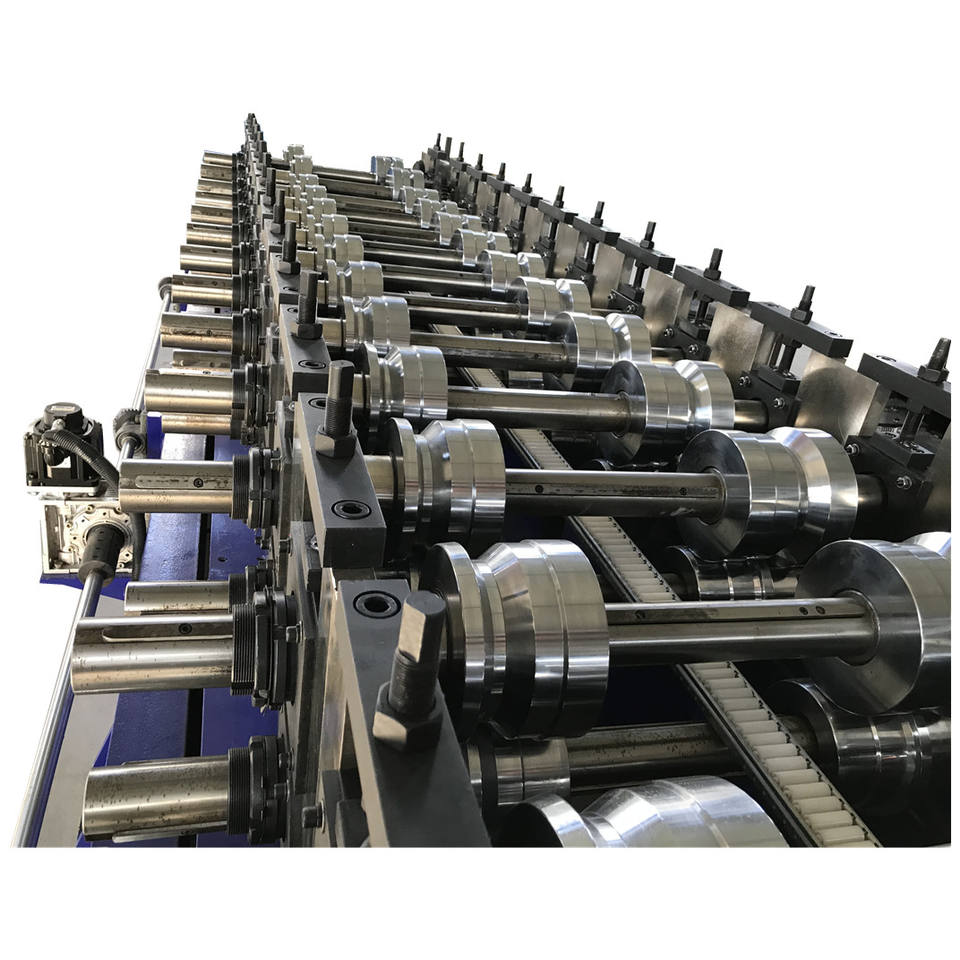

1.Superior Forming Precision, Consistent Quality

Equipped with high-hardness alloy rollers (HRC 58-62) and a precision-guided transmission system, the machine ensures uniform seam height, tight locking, and smooth surface finish for every metal sheet. The error margin of seam dimensions is controlled within ±0.1mm, perfectly meeting the strict standards of architectural and industrial roofing applications. No more rework—just reliable, consistent products batch after batch.

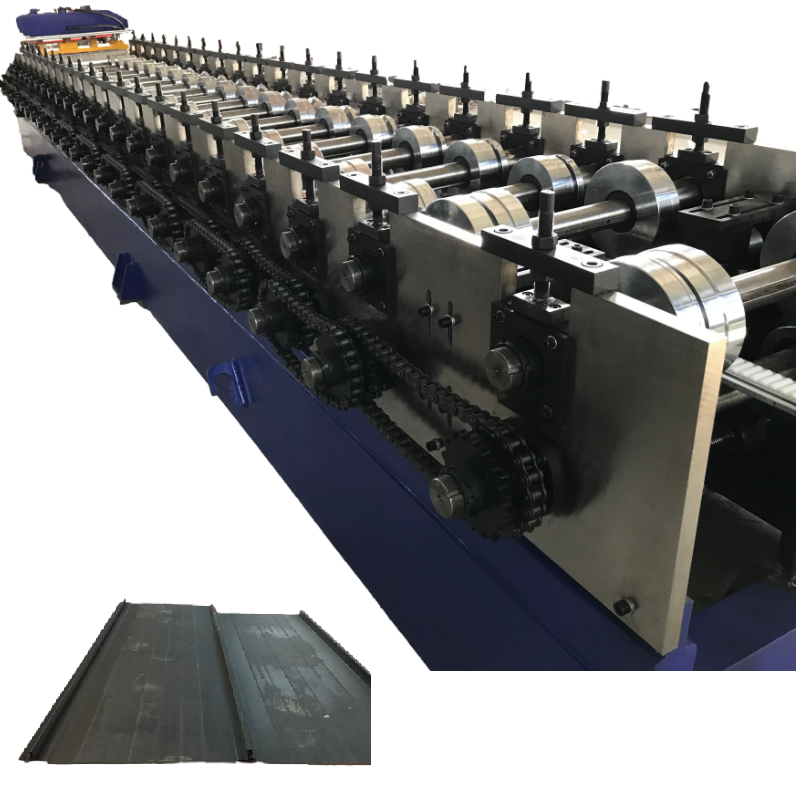

2.High-Speed Production, Maximized Output

With a maximum forming speed of 15-20m/min (adjustable according to material thickness), the machine significantly outperforms traditional equipment. It supports continuous feeding and automatic cutting, minimizing downtime between processes. Whether processing aluminum, galvanized steel, or color-coated steel (0.3-1.2mm thickness), it maintains stable performance, helping you fulfill large orders efficiently and meet tight delivery deadlines.

3.Flexible Customization, Wide Application

We understand that different markets have diverse requirements. Our machine offers flexible adjustment of seam types (such as snap-lock, mechanical lock) and sheet widths (300-600mm customizable). It is ideal for manufacturing standing seam roofing panels, wall cladding, and decorative metal sheets used in commercial buildings, industrial warehouses, villas, and agricultural facilities—adapting to your specific project needs with ease.

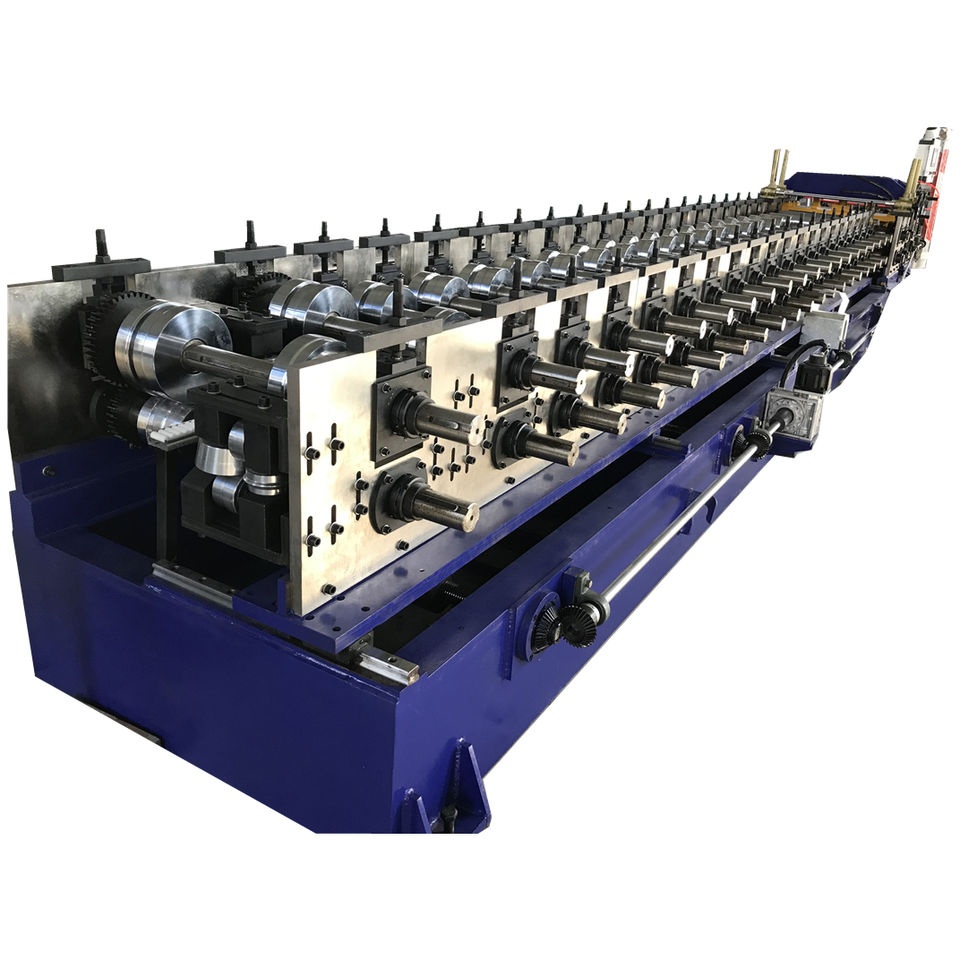

4.Durable Structure, Low Maintenance Cost

The main frame is made of heavy-duty steel with integral welding and tempering treatment, ensuring strong load-bearing capacity and resistance to deformation. Key components are sourced from international brands, reducing failure rates. The machine features a modular design, making routine maintenance and part replacement simple—lowering your long-term operation costs.

5.Intelligent Operation, Easy to Master

Equipped with a touch-screen control system, the machine allows one-click setting of parameters (length, quantity, speed) and real-time monitoring of production status. It has built-in fault alarm functions (such as material shortage, overload) to avoid production accidents. Even new operators can master the operation within a short training period, reducing labor costs.

スタンディングシームマシン ビデオチャンネル

私たちを選ぶ理由

OEM/ODM&カスタマイズワンストップサービス

充実したアフターサービス

OEM、ODMの提供

2.技術者の設計: デッサンのプロフィールおよび 3D 機械デッサンを作って下さい

3.構成と生産を決定する

4.納品前テスト

6.技術指導

7.アフターサービス:複雑な機械の設置サービスと定期的な顧客訪問

95800社以上の信頼

質の高い企業です。私たちとの協力を通じて、彼らは次のようなものを得ています。

強力なサポートを得て、事業の躍進と発展を遂げた。