技術的変化と産業システム、私たちの使命

セッズは、お客様にとって最善かつ経済的なソリューションを提供します。

Revolutionize Your Roofing Projects with Our Arc Roof Panel Forming Machine

冷間ロール成形機の異なるタイプ。私達は 2006 年以来の機械を形作るロールの設計そして製造で従事している長い歴史の工場です。私達が作り出してもいい機械は下記のものを含んでいます: 機械、機械を作る cz の母屋を作る屋根瓦機械、機械を作る軽い鋼鉄キール、金属浮彫りになる機械、機械を形作るドア システム天井システム高周波管の溶接機、ラインを切り開くこと、長さライン、機械を形作る棚システムを形作る床 Decking 機械、色の石造りのタイルの生産ライン、熱い薄板になるフィルムで形造る機械、等を切ります。

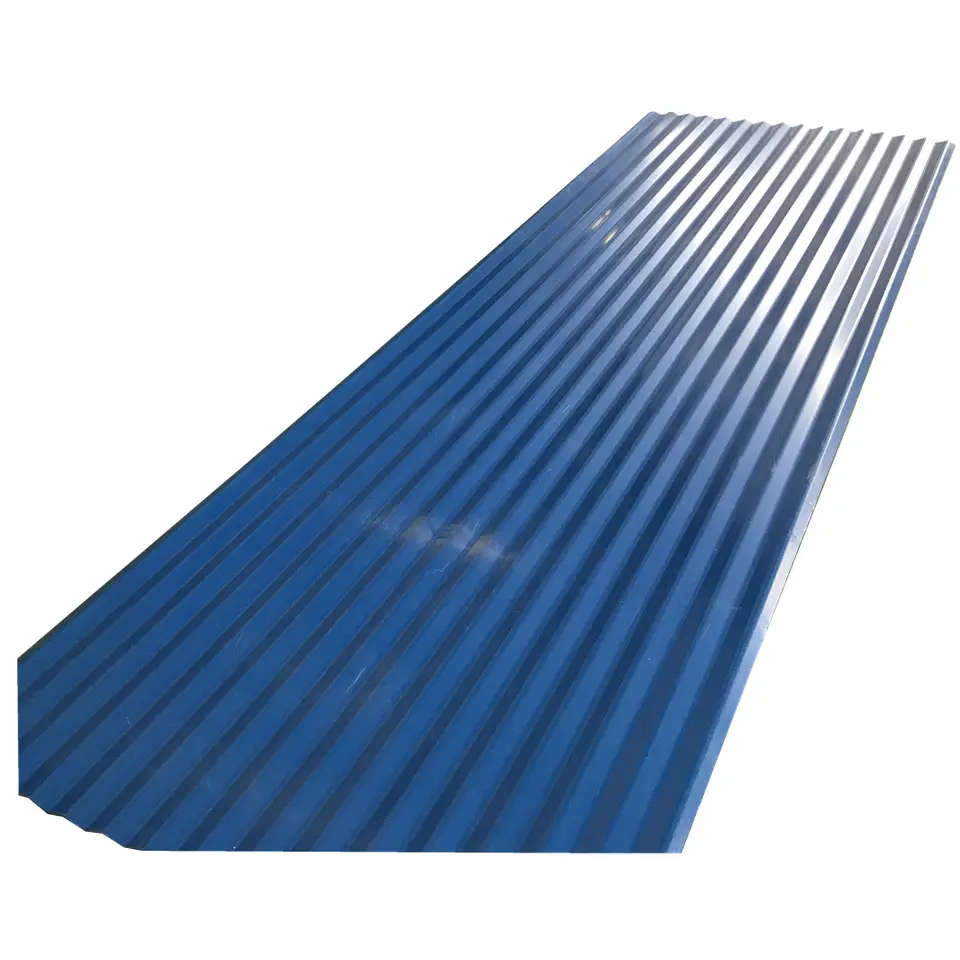

In the dynamic realm of modern construction, the pursuit of innovative and functional building designs has become a cornerstone for architects, builders, and developers worldwide. One design element that has been gaining significant traction is the use of arc – shaped roof panels. These panels not only add a touch of elegance and uniqueness to structures but also offer a host of practical advantages, from enhanced structural integrity to improved weather resistance.

The Arc Roof Panel Forming Machine, the key equipment for producing such arc – shaped roof panels, has thus become an essential asset in the construction machinery market. It is the driving force behind the transformation of flat metal sheets into precisely – curved, high – quality roof panels that meet the diverse needs of contemporary construction projects. Whether it’s for large – scale commercial buildings, industrial facilities, or even residential homes, the Arc Roof Panel Forming Machine plays a pivotal role in bringing architectural visions to life.

High – Precision Forming

Our arc roof panel forming machine is equipped with state – of – the – art servo control systems and advanced digital programming technology. This combination enables the machine to achieve an astonishing forming accuracy of ±0.5mm. Whether it’s a gentle curve for a residential villa or a more complex, sharp arc for a large – scale commercial dome, the machine can precisely replicate the design specifications. The high – precision forming not only ensures the aesthetic appeal of the arc – shaped roof panels but also significantly improves their structural integrity. For example, in the construction of a large – scale exhibition center, the precise curvature of the roof panels, achieved by our forming machine, allowed for seamless integration with the overall building structure, enhancing the building’s stability and durability.

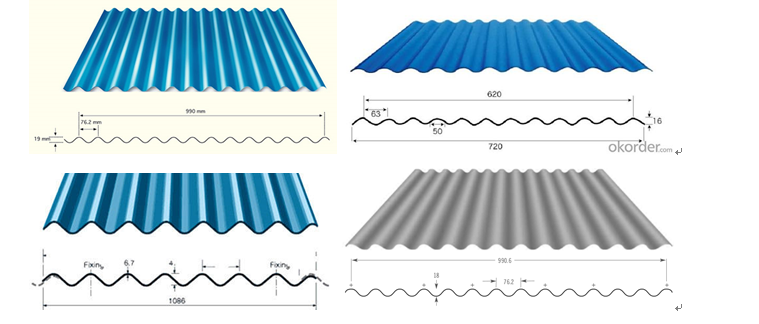

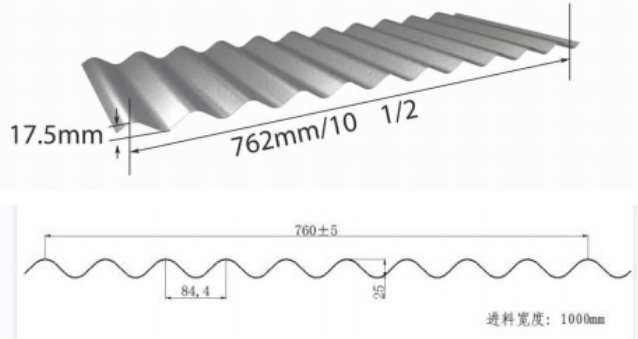

Customizable Options

We understand that every construction project is unique, and thus our arc roof panel forming machine offers a wide range of customizable options. It can produce roof panels with different radii of curvature, ranging from a minimum of 2 meters to a maximum of 10 meters, catering to various architectural designs. The thickness of the processed metal sheets can be adjusted from 0.3mm to 1.5mm, and the width can be customized from 800mm to 1200mm. This flexibility allows our clients to meet the specific requirements of their projects, whether it’s for a cost – effective small – scale project using thinner and narrower panels or a high – end luxury building demanding thicker and wider, more robust panels.

High – Efficiency Production

Designed for high – volume production, our forming machine is a paragon of efficiency. It has a production speed of up to 15 meters per minute, which means it can produce a significant amount of arc – shaped roof panels in a short time. The machine is also highly automated, with an automatic feeding system, a computer – controlled length – setting and cutting mechanism, and a quick – change mold system. The automatic feeding system can continuously supply metal sheets to the machine, eliminating the need for manual intervention during the feeding process. The computer – controlled length – setting and cutting mechanism ensures accurate cutting of the formed panels, reducing material waste. And the quick – change mold system allows for rapid switching between different panel profiles, further enhancing production efficiency.

Robust and Durable Construction

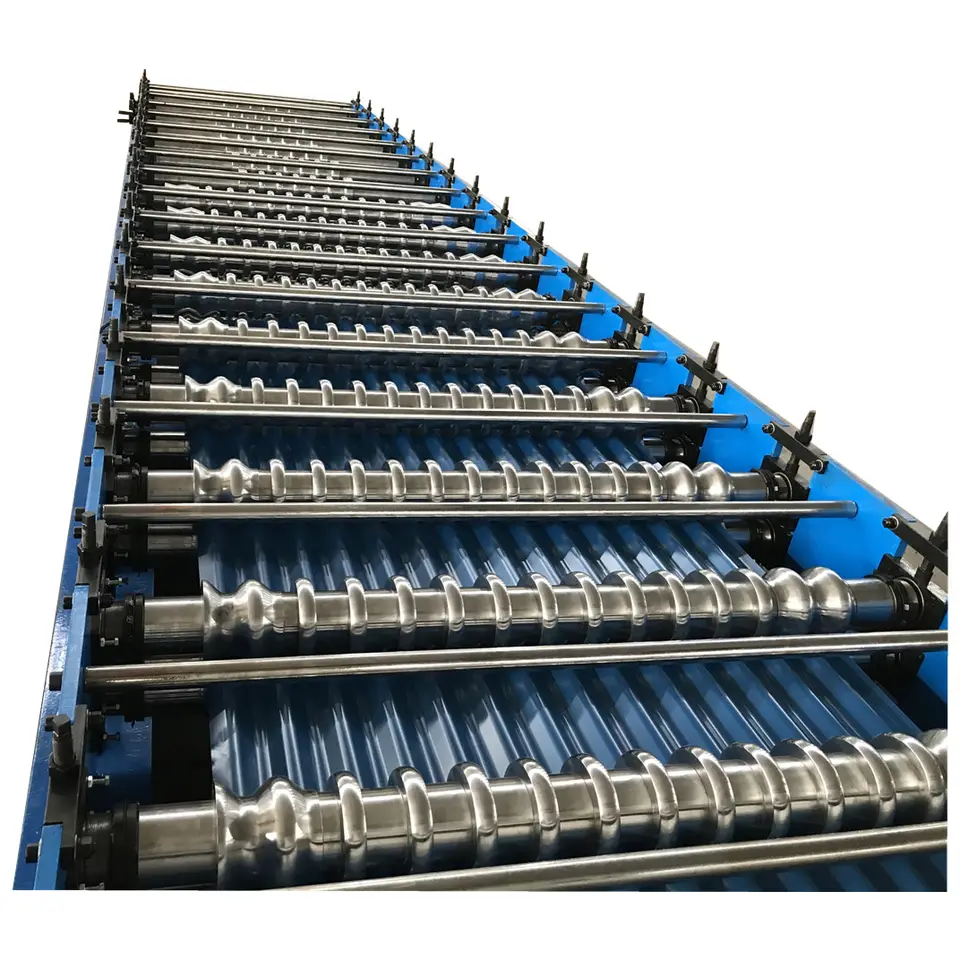

Built to last, our arc roof panel forming machine features a robust construction. The main frame is made of high – strength steel, which has excellent load – bearing capacity and can withstand the rigors of continuous operation. The rollers are crafted from high – quality alloy steel, heat – treated to enhance their hardness and wear resistance. The surface of the rollers is also precision – ground and chrome – plated, reducing friction and extending the service life of the rollers. Additionally, the machine is equipped with a comprehensive lubrication system that ensures all moving parts are properly lubricated at all times, minimizing wear and tear. This durable construction enables the machine to operate smoothly even in harsh working environments, such as in dusty construction sites or areas with high humidity.

Technical Specifications at a Glance

| Parameter | Details |

| Overall Dimensions | Length: 12 – 15 meters, Width: 1.3 – 1.5 meters, Height: 1.2 – 1.4 meters |

| Machine Weight | Approximately 5 – 8 tons |

| Power Consumption | Main Motor Power: 7.5 – 11 KW; Hydraulic Station Motor Power: 2.2 – 3 KW |

| Applicable Plate Thickness Range | 0.3 – 1.5 mm |

| Applicable Plate Width Range | 800 – 1200 mm |

| 成形速度 | Up to 10 meters per minute |

| Forming Accuracy | ±0.5mm |

| Curvature Radius Range | Minimum: 2 meters; Maximum: 10 meters |

| Roll Material | High – quality alloy steel, heat – treated, surface precision – ground and chrome – plated |

| Frame Material | High – strength steel |

| Control System | Advanced servo control system with digital programming, PLC – based control for high – precision operation |

Wide Applications in the Construction Industry

Industrial Buildings

In industrial buildings such as factories and warehouses, arc – shaped roof panels produced by our forming machine offer numerous advantages. Firstly, their unique shape allows for better space utilization. The smooth curve of the roof panels can create a more open – and – airy interior space, eliminating the need for excessive internal supporting structures that might otherwise take up valuable floor space. This is particularly beneficial for factories with large – scale production equipment that requires unobstructed areas for operation and movement.

Secondly, the drainage performance of arc – shaped roof panels is outstanding. The curved surface naturally guides rainwater towards the eaves or drainage systems, reducing the risk of water accumulation on the roof. In areas with heavy rainfall, this feature can significantly enhance the durability of the building, as standing water can cause corrosion and damage to the roof structure over time. For example, in a large – scale industrial plant located in a region with frequent typhoons and heavy rains, the use of arc – shaped roof panels produced by our forming machine has effectively withstood the test of extreme weather conditions, ensuring the normal operation of the factory without any roof – related water leakage issues.

Commercial Buildings

In commercial buildings like shopping malls and exhibition halls, the arc – shaped roof panels produced by our equipment bring a perfect combination of aesthetics and practicality. From an aesthetic perspective, the graceful curves of the roof panels can add a touch of modernity and elegance to the building’s exterior, making it more eye – catching and appealing to customers. In a bustling shopping district, a mall with an arc – shaped roof stands out among the surrounding rectangular – shaped buildings, attracting more foot traffic due to its unique architectural style.

Functionally, these roof panels can also provide better insulation and sound – proofing properties. In a large – scale exhibition hall, where various events and exhibitions are held, the excellent insulation of the arc – shaped roof panels helps maintain a stable indoor temperature, reducing the energy consumption of heating and cooling systems. At the same time, the sound – proofing function can effectively isolate external noise, creating a quiet and comfortable environment for exhibitions and visitors. For instance, a well – known international exhibition center renovated its roof using our arc – shaped roof panels. After the renovation, not only did the building’s appearance become more stunning, but also the interior environment became more conducive to hosting high – end exhibitions, receiving widespread acclaim from exhibitors and visitors.

Residential Buildings

In residential buildings, especially in villas and high – end houses, the application of arc – shaped roof panels has its own unique characteristics. One of the most prominent features is that it can significantly enhance the overall style of the building. The curved roof adds a sense of luxury and uniqueness, making the house stand out in the neighborhood. It can also blend well with different architectural styles, whether it is a Mediterranean – style villa with its warm – toned walls and terracotta – colored arc – shaped roof panels, or a modern – minimalist high – end house with sleek, silver – gray arc – shaped metal roof panels.

Moreover, the arc – shaped roof can also improve the living comfort of residents. It can create a more spacious – feeling attic space under the roof, which can be used as a study, a leisure area, or a storage room. The unique shape also allows for better natural lighting and ventilation. Sunlight can penetrate deeper into the rooms through the curved roof, brightening up the interior, and the natural ventilation effect is enhanced, ensuring fresh air circulation throughout the house. For example, in a luxury villa area, many homeowners have chosen to use arc – shaped roof panels for their houses. The result is not only a group of beautiful and unique – looking residences but also a more comfortable and healthy living environment for the residents.

波形屋根シートマシン ビデオチャンネル

私たちを選ぶ理由

OEM/ODM&カスタマイズワンストップサービス

充実したアフターサービス

OEM、ODMの提供

2.技術者の設計: デッサンのプロフィールおよび 3D 機械デッサンを作って下さい

3.構成と生産を決定する

4.納品前テスト

6.技術指導

7.アフターサービス:複雑な機械の設置サービスと定期的な顧客訪問

95800社以上の信頼

質の高い企業です。私たちとの協力を通じて、彼らは次のようなものを得ています。

強力なサポートを得て、事業の躍進と発展を遂げた。