技術的変化と産業システム、私たちの使命

セッズは、お客様にとって最善かつ経済的なソリューションを提供します。

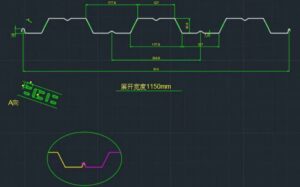

1150mm の入力コイルの幅を使用して 915 のための機械を形作る床の金属のデッキ

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

1150mm の入力コイルの幅を使用して 915 のための機械を形作る床の金属のデッキ

Our Floor Metal Deck Forming Machine For 915 using 1150mm input coil width, here is the drawing profile for your reference:

Floor Metal Deck Forming Machine finished products:

Floor Metal Deck Forming Machine design:

Advantage of Floor Metal Deck Forming Machine:

Adopt 85-95mm solid shaft and H-shaped steel as the under frame, so that the machine can withstand long-term production without deformation of the machine, thus ensuring long-term machine use life; For the metal embossing rollers, we use the 120mm diameter strong shaft, meanwhile with the keynote design.

The rollers are processed by CNC machine tools to ensure the accuracy of the rollers, and thus the accuracy of the final deck. For the metal embossing roller, we design with the brake system and then you can feed the coil easily and make sure the embossing is nice the accurate.

Our cut blade frame is stress-relieved to ensure that it is not deformed during long-term production and makes the final product smooth. Frame shearing system is good for the long time to use.

The steel decks are flat, high precision within 1mm, and the effective width is controlled within 5mm; When shearing there will be some wasted coil.

Use Mitsubishi or Siemens operating system with stable performance, simple operation, as long as the input length and quantity are automatically produced by the machine, and the cutting length tolerance is within ± 2mm

Forming speed can reach 8-12 meters per minute

The machine weighs about 15-18 tons

For the testing and quality control we are quite seriously.

Why choose us?

OEM/ODM&カスタマイズワンストップサービス

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

95800社以上の信頼

質の高い企業です。私たちとの協力を通じて、彼らは次のようなものを得ています。

強力なサポートを得て、事業の躍進と発展を遂げた。