技術的変化と産業システム、私たちの使命

セッズは、お客様にとって最善かつ経済的なソリューションを提供します。

ケーブルラダーフレームZプロファイル圧延成形機

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc. Cable ladder frame Z profile rolling forming machine is designed to make the ladder frame in batch fully automatically.

ケーブルラダーフレームZプロファイル圧延成形機

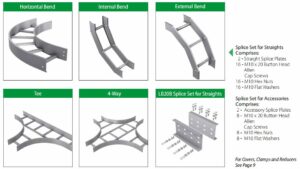

Cable ladder frame Z profile rolling forming machine is designed to make the ladder frame in batch fully automatically. This cable ladder range is a complete cable support system that is easily assembled on site and it is is specifically designed to carry electrical cables in horizontally mounted, heavy duty industrial and mining applications. Here are some usage cases for your reference:

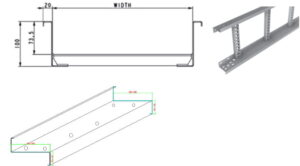

This type ladder is composed by two parts, the Z frame part and the C connection beam with punching. Here is the drawing profiles for your reference. By this type, the ladder could be any width. And for the Z frame, you can choose to do the punching online or offline.

Cable ladder frame Z profile rolling forming machine:

Z frame roll forming parameters for your reference:

Main motor power: 18.5kw

Drive: Chain

Main shaft dia: ¢85mm, material: 45﹟refined forge steel

Roller material: GCr15 bearing steel, quenching HRC58-62,surface coated chrome with thickness 0.05mm

Roll station: 16stations with 7 leveling rollers

Raw material: Black steel or galvanized steel

Thickness of raw material: 2-3mm

Working speed: about 7-15m/min(include cutting time)

Coder: OMROM

PLC: YASKAWA , made in Japan. 380V 50HZ(Depend on customer)

Computer operating panel: touching screen

And for the shearing system:

Hydraulic cutting

Four sets of the cutting mould to replace for different size

Hydraulic power: 5.5KW

Hydraulic pressure: 20Mpa

Blade material: Cr12mov, quenched 58°-62°

This machine we design is slow speed and more economic. If you want to make more sizes and like more high speed machine, we could make also. There are other types same working principle, we could also make.

For this type machine, if you want to know more information, please contact us at any time.

私たちを選ぶ理由

OEM/ODM&カスタマイズワンストップサービス

充実したアフターサービス

OEM、ODMの提供

2.技術者の設計: デッサンのプロフィールおよび 3D 機械デッサンを作って下さい

3.構成と生産を決定する

4.納品前テスト

6.技術指導

7.アフターサービス:複雑な機械の設置サービスと定期的な顧客訪問

95800社以上の信頼

質の高い企業です。私たちとの協力を通じて、彼らは次のようなものを得ています。

強力なサポートを得て、事業の躍進と発展を遂げた。