技術的変化と産業システム、私たちの使命

セッズは、お客様にとって最善かつ経済的なソリューションを提供します。

自動 C 形母屋クイック変更サイズ ロール成形機

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

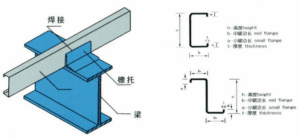

C section purlins or cee section purlins are designed to form the walls and floor joists of a building shell structure, making

them also ideal for supporting beams needed for mezzanine flooring.

Our Automatic C shaped Purlin Quick Change Size Roll Forming Machine is used to produce the C section purlins,our machine is also customized as customer’s request.

Standard size:80-300mm(customized)

Standard thickness:max 3mm(customized)

C-shaped purlin, also known as C-shaped steel or C-shaped purlin, is a common cold-formed thin-walled steel structural component. They are widely used in various building structures due to their excellent mechanical properties, high strength to weight ratio, and ease of installation.

Industrial and commercial buildings:

In large industrial buildings such as factories and warehouses, C-shaped purlins are used as support structures for roofs and walls.

Commercial complexes such as shopping centers and office buildings also use C-shaped purlins to construct lightweight and stable structures.

Agricultural facilities:

Greenhouse: C-shaped purlins, due to their good corrosion resistance (usually treated with galvanizing), are suitable for the skeleton of greenhouses and support plastic film or other covering materials.

Livestock shed: used to construct roofs and wall supports for livestock sheds.

Purlin machine video channel

Why choose us?

OEM/ODM&カスタマイズワンストップサービス

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

95800社以上の信頼

質の高い企業です。私たちとの協力を通じて、彼らは次のようなものを得ています。

強力なサポートを得て、事業の躍進と発展を遂げた。