技術的変化と産業システム、私たちの使命

セッズは、お客様にとって最善かつ経済的なソリューションを提供します。

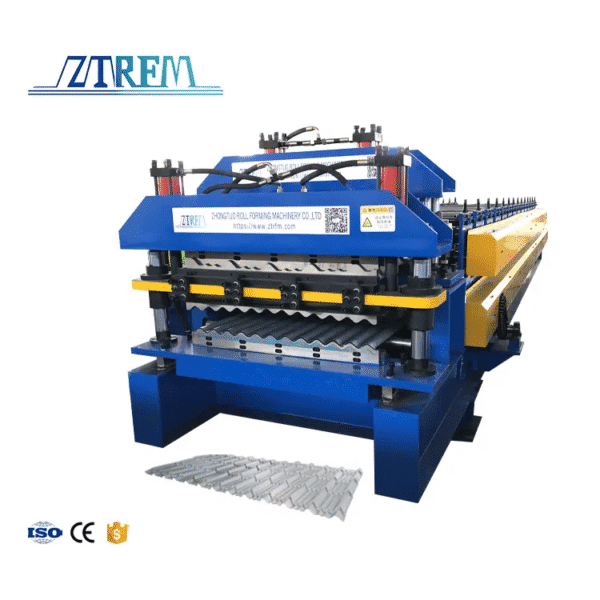

Automatic Double-layer Steel Roof Panel Roll Pressing Machine

冷間ロール成形機の異なるタイプ。私達は 2006 年以来の機械を形作るロールの設計そして製造で従事している長い歴史の工場です。私達が作り出してもいい機械は下記のものを含んでいます: 機械、機械を作る cz の母屋を作る屋根瓦機械、機械を作る軽い鋼鉄キール、金属浮彫りになる機械、機械を形作るドア システム天井システム高周波管の溶接機、ラインを切り開くこと、長さライン、機械を形作る棚システムを形作る床 Decking 機械、色の石造りのタイルの生産ライン、熱い薄板になるフィルムで形造る機械、等を切ります。

The innovative design of the double-layer steel roof sheet roll forming machine has revolutionized the limitations of traditional single-line production, making it the preferred equipment for industrial plants, warehousing and logistics centers, and residential buildings.

Precision Control System of Double Layer Molding

Our forming machine employs the core technology of ‘zoned drive + intelligent calibration’ to digitally control the entire process of converting steel strips into high-precision double-layer roof panels, ensuring both upper and lower layers meet international standards.

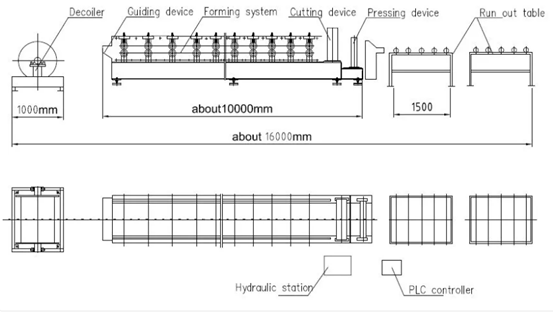

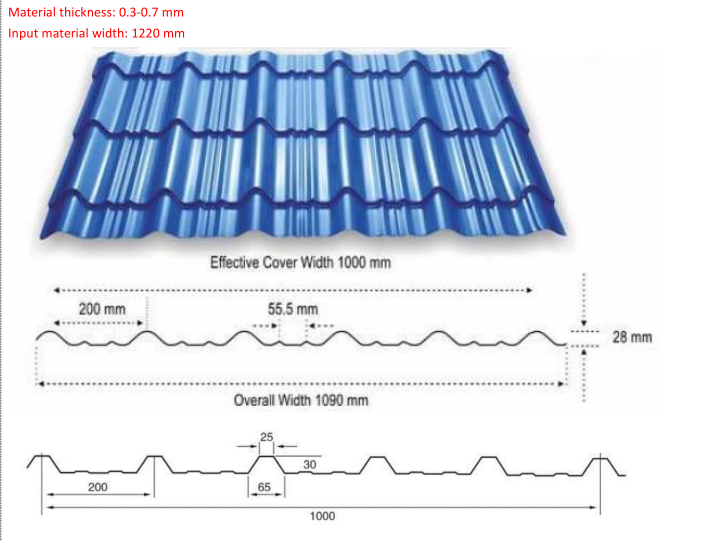

The raw material processing stage establishes dual safeguards: A 5-ton hydraulic uncoiler paired with a four-stage leveling system enables stable handling of various substrates, including color-coated steel plates, galvanized steel plates, and aluminum alloy plates, with widths ranging from 800 to 1220mm and thicknesses from 0.5 to 0.18-1.0mm. Through hydraulic tension control and laser alignment, feed deviations are maintained within ±0.05mm. The core forming stage employs a ‘dual independent roll system,’ featuring 24 corrugated plate forming rolls on the upper layer and 18 glazed tile forming rolls on the lower layer. These rolls are coated with hard chrome on 45# steel, achieving a surface roughness of Ra0.8μm to ensure scratch-free and pressure-free sheet formation.

Quality upgrade

The double-layer roof panels manufactured by our equipment achieve dual breakthroughs in mechanical performance and waterproofing. Third-party tests confirm that the corrugated panels exhibit a bending strength of 280MPa, while the glazed tiles demonstrate a flexural strength of 150MPa—both surpassing international standards by 30%. The proprietary edge-biting molding process enhances inter-panel overlap sealing by 80%, and when paired with specialized sealing strips, it achieves a water resistance of 0.3MPa, effectively resolving leakage issues common in traditional roof panels. In a Thai industrial park project, the panels produced by our equipment have been in stable service for 12 years, remaining rust-free and deformation-free despite exposure to tropical storms and intense UV radiation.

Full-scenario adaptation: from tropical typhoon zone to cold zone

To address diverse global climate and architectural requirements, our forming facility has developed a “multi-pattern, multi-material, and customized” adaptation system. The system covers 12 mainstream roofing panel types, including 840/850/900 corrugated sheets, glazed tiles, and antique-style tiles. Production can be achieved by combining any two panel types through rapid roller group replacement (type change ≤45 minutes). Material compatibility spans from standard color-coated steel sheets to 550MPa high-strength galvanized sheets, and from aluminum alloy plates to corrosion-resistant weathering steel, all achieving perfect forming through intelligent parameter adjustments.

私たちを選ぶ理由

OEM/ODM&カスタマイズワンストップサービス

充実したアフターサービス

OEM、ODMの提供

2.技術者の設計: デッサンのプロフィールおよび 3D 機械デッサンを作って下さい

3.構成と生産を決定する

4.納品前テスト

6.技術指導

7.アフターサービス:複雑な機械の設置サービスと定期的な顧客訪問

95800社以上の信頼

質の高い企業です。私たちとの協力を通じて、彼らは次のようなものを得ています。

強力なサポートを得て、事業の躍進と発展を遂げた。