Cambiamenti tecnologici e sistemi industriali, ci dedichiamo a

Fornisce a Seds le migliori e più economiche soluzioni ai suoi clienti.

Telaio della porta in metallo telaio del muro a secco rotolamento formando macchina

diversi tipi di macchine per la profilatura a freddo. Siamo una fabbrica con una lunga storia, impegnata nella progettazione e nella produzione di macchine profilatrici dal 2006. Le macchine che possiamo produrre includono: macchina per la produzione di tegole, macchina per la produzione di arcarecci in cz, macchina per la produzione di chiglie in acciaio leggero, macchina per la goffratura dei metalli, macchina per la formazione di sistemi di porte, macchina per la formazione di sistemi di soffitti, macchina per la saldatura di tubi ad alta frequenza, linea di taglio, linea di taglio a misura, macchina per la formazione di sistemi di scaffali, macchina per la formazione di decking per pavimenti, linea di produzione di piastrelle in pietra colorata, macchina per la laminazione a caldo filmata, ecc.

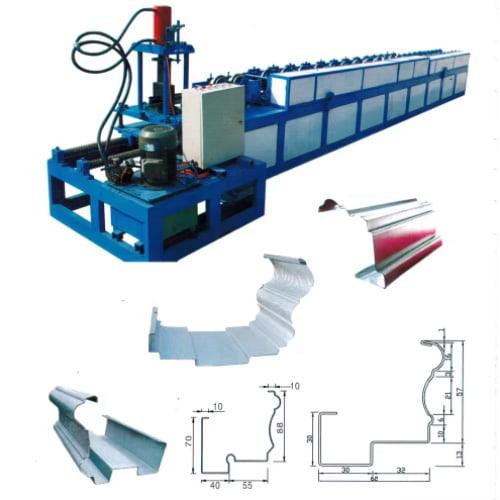

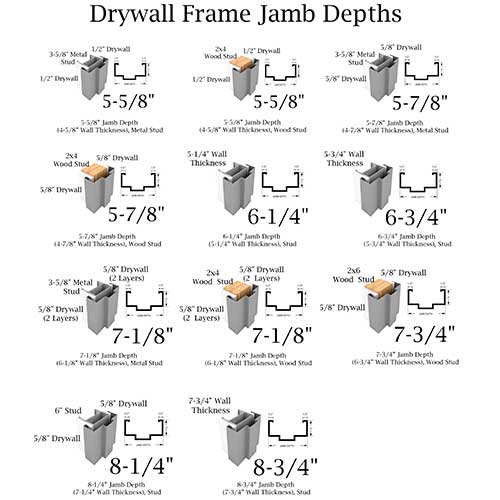

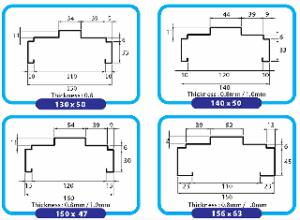

Metal door frame rolling forming machine is designed to make the metal door frame in batch fully automatically. The knocked down drywall frame is for interior stud walls and for use with steel or wood doors. Drywall frames are designed for light to heavy duty applications in both commercial and institutional buildings. Frames are installed in rough openings after the wall has been constructed and finished. They are supplied with a (knock-down) corner for quick installation. As to the metal door frame rolling forming machine we can make it either half automatic type or fully automatic type with online punching for hinges holes. Here are some standard metal door frame drawing profile for your reference:

Metal door frame rolling forming machine is designed to make the metal door frame in batch fully automatically.

Title: Metal drywall door frame rolling forming machine

Keywords: drywall door frame machine, rolling forming machine

Metallo telaio porta muro a secco rotolamento formando macchina

A hollow metal door frame is a type of door frame constructed from steel that has been formed into a hollow profile. This design provides structural integrity and durability while keeping the weight of the frame relatively light. Hollow metal door frames are commonly used in commercial and industrial buildings due to their strength and resistance to wear and tear. Here are some popular drawing profile for your reference:

Hollow metal door frames offer several advantages, including:

– Strength: They are very strong and can support heavy doors.

– Fire Rating: Many hollow metal frames are fire-rated and can withstand fire for a certain period of time.

– Security: The solid construction resists forced entry.

– Durability: They are resistant to warping, cracking, and damage from environmental factors.

-Customization: Hollow metal frames can be easily modified on-site to fit various door sizes and requirements.

Based on those we make the metal door frame rolling forming machine either has the fully automatic and half automatic metal door frame rolling machine.

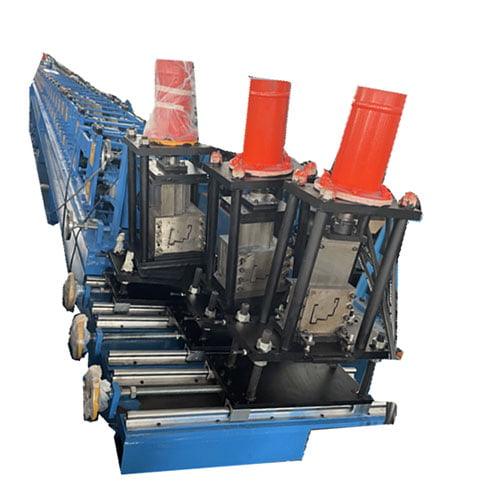

Metal door frame machine is a specialized piece of equipment used in the manufacturing process of hollow metal door frames. This machine is designed to shape or form steel strips or profiles into the desired shape of a door frame by a process called rolling.

The main features and functions of a metal door frame rolling machine may include:

- Rolling Process: The machine uses a series of rollers to bend and shape the steel strips into the U-shaped or C-shaped profile that makes up the door frame.

- Adaptability: The machine is often adjustable to accommodate different sizes and types of door frames, allowing for versatility in production.

- Automation: Modern machines can be automated to increase production efficiency and reduce labor costs. They can be programmed to produce frames of consistent size and shape.Take an example for the 45 degree shearing part, you can choose either online or offline. Also for the punching, you can also make based offline or online. For more information, you can contact me at any time.

Perché scegliere noi?

OEM/ODM e servizio di personalizzazione one-stop

Assistenza post-vendita completa

Fornire OEM、ODM

2.Progettazione tecnica: realizzazione di profili di disegno e disegno di macchine 3D

3.determinare la configurazione e la produzione

4.test prima della consegna

6.Guida tecnica

7.Servizio post-vendita: servizi di installazione per macchine complesse e visite periodiche ai clienti.

Affidato da oltre 95800 aziende

imprese di alta qualità. Grazie alla collaborazione con noi, hanno ricevuto

forte sostegno e ha ottenuto progressi e sviluppi commerciali.